10. ASSEMBLY

KE-430F, BE-438F

90

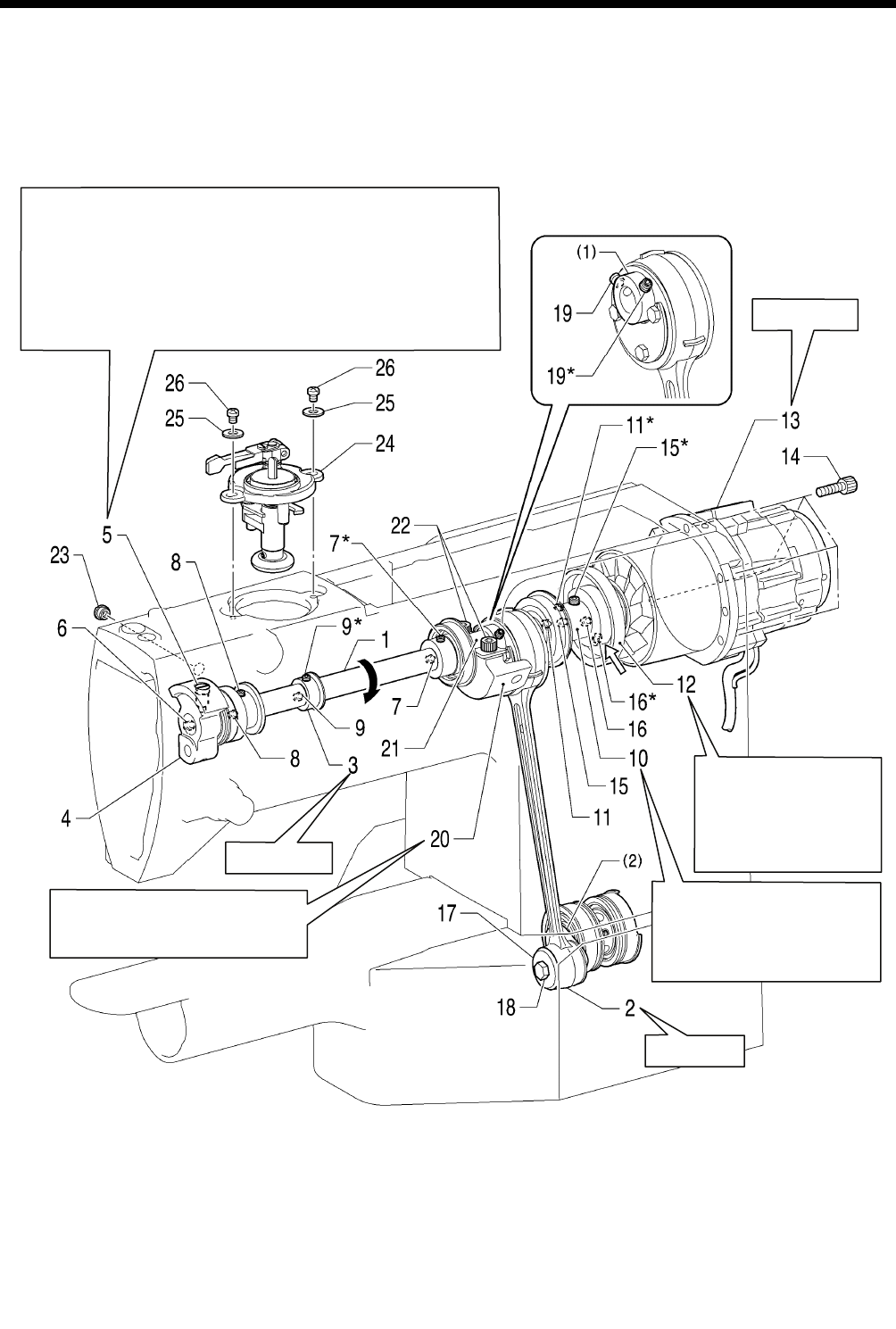

10-8. Upper shaft mechanism

Apply grease <GREASE BZL-300P> specified by Brother to the portions indicated by the white arrows.

* 17, 18 and 19 should be installed after carrying out the installations in “10-10. Lower shaft mechanism”.

* Set screws marked with * in the illustration are on the screw stop side.

* Refer to the next page for the points to note during reassembly.

(Continued on next page.)

1. Upper shaft

2. Crank rod base

3. Pulley gear R

4. Thread take-up crank

5. Screw

6. Set screw [Tighten]

7. Set screws [2 pcs: Tighten]

8. Set screws [2 pcs: Tighten]

9. Set screws [2 pcs: Tighten]

10. Joint assembly

21. Balancer plate

22. Bolts [2 pcs]

23. Rubber cap

24. Bobbin winder unite

25. Plain washers [2 pcs]

26. Screws [2 pcs]

1) Tighten the screw 5 of the thread take-up crank 4 so that it

is aligned with the hole in the upper shaft 1.

2) While pressing the thread take-up crank 4 so that there is

no play in it, tighten the two set screws 7.

Apply adhesive (Threebond 1401 or similar) to the thread

section of the screw 5.

Apply adhesive (Threebond

1324 or similar) to the outer

circumference of the joint

assembly bearing 10.

・ A on next page

・ Adjust while referring

to “11-14. Adjusting

the thread trimmer

cam position”.

・ D on next page

・ Be careful not to drop the

balancer 20.

11. Set screws [2 pcs: Tighten]

12. Thread trimmer cam

13. Motor assembly

14. Bolts [4 pcs]

15. Set screws [2 pcs: Tighten]

16. Set screws [2 pcs: Tighten]

17. Crank rod washer

18. Bolt

19. Set screws [2 pcs: Tighten]

20. Balancer

(1) Eccentric wheel

(2) Rock gear shaft assembly

2860B

C on next page

B on next page

E on next page