Troubleshooting and Service Teledyne API Model T360/T360M Operation Manual

260

8.7. FREQUENTLY ASKED QUESTIONS

The following is a list from the Teledyne API’s Technical Support Department of

the most commonly asked questions relating to the Model CO

2

Analyzer.

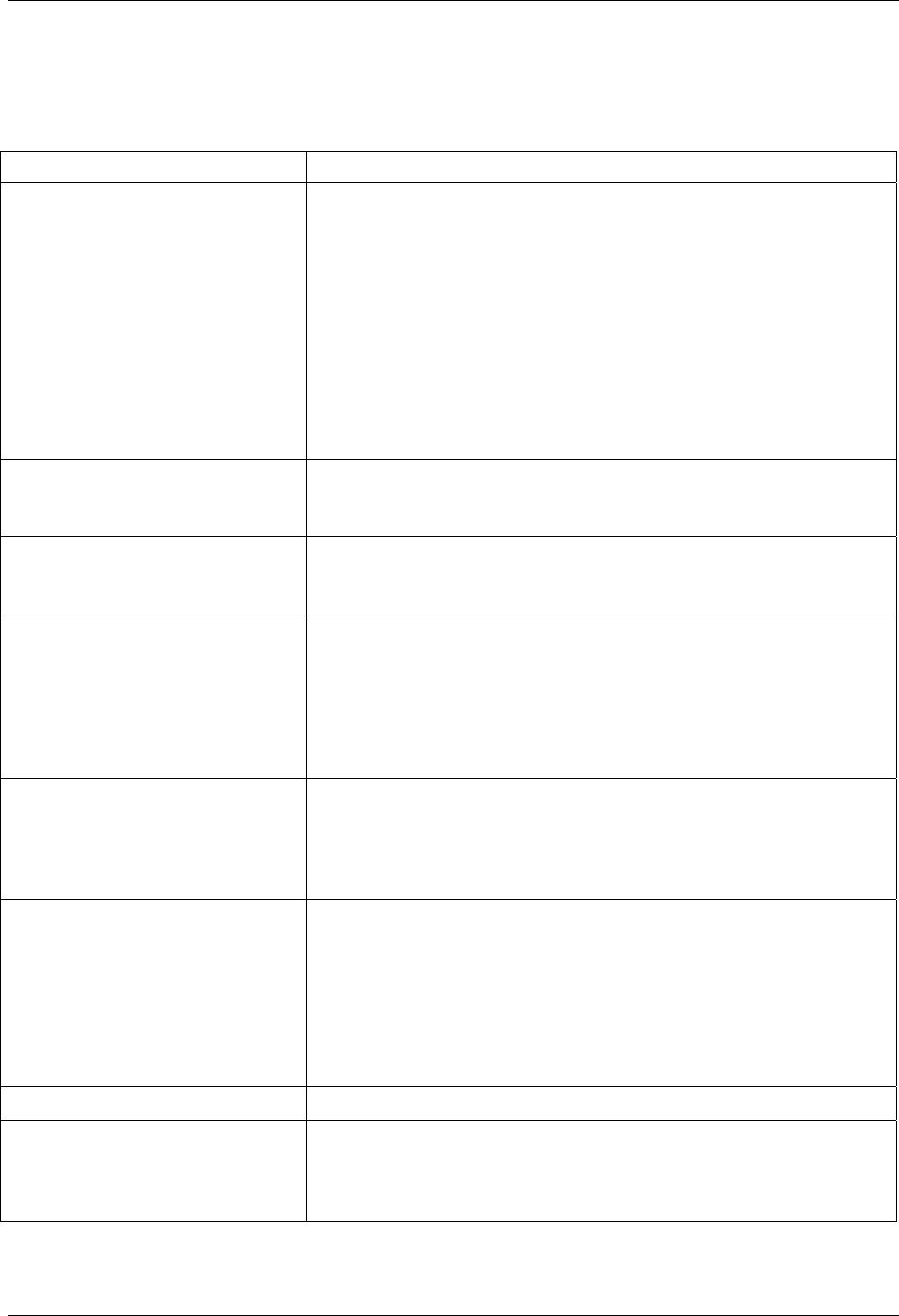

Question Answer

Why does the instrument not

appear on the LAN or Internet?

Most problems related to Internet communications via the Ethernet

card will be due to problems external to the instrument (e.g. bad

network wiring or connections, failed routers, malfunctioning

servers, etc.) However, there are several symptoms that indicate

the problem may be with the Ethernet card itself. If neither of the

Ethernet cable’s two status LED’s (located on the back of the cable

connector) is lit while the instrument is connected to a network:

Verify that the instrument is being connected to an active

network jack.

Check the internal cable connection between the Ethernet card

and the CPU board.

How do I get the instrument to

zero / Why is the zero button not

displayed?

See Section 8.3.4 Inability to zero.

How do I get the instrument to

span / Why is the span button not

displayed?

See Section 8.3.3 Inability to span.

Why does the ENTR button

sometimes disappear on the

Front Panel Display?

During certain types of adjustments or configuration operations, the

ENTR button will disappear if you select a setting that is

nonsensical (such as trying to set the 24-hour clock to 25:00:00) or

out of the allowable range for that parameter (such as selecting a

DAS Holdoff period of more than 20 minutes). Once you adjust the

setting in question to an allowable value, the

ENTR button will re-

appear.

Is there an optional midpoint

calibration?

There is an optional mid point linearity adjustment; however,

midpoint adjustment is applicable only to applications where CO

2

measurements are expected above 100 ppm. Call Teledyne

Instrument’s Technical Support Department for more information on

this topic.

How do I make the display and

data logger analog input agree?

This most commonly occurs when an independent metering device

is used besides the data logger/recorded to determine gas

concentration levels while calibrating the analyzer. These

disagreements result from the analyzer, the metering device and

the data logger having slightly different ground levels. Both the

electronic scale and offset of the analog outputs can be adjusted

(see Section 4.13.4.3). Alternatively, use the data log

ger itself a

s

the metering device during calibrations procedures.

How do I perform a leak check? See Section 6.3.3.

How do I measure the sample

flow

Sample flow is measured by attaching a calibrated rotameter, wet

test meter, or other flow-measuring device to the sample inlet port

when the instrument is operating. The sample flow should be 800

cm

3

/min 10%. See Section 6.3.4.

07272B DCN6552