Principles of Operation Teledyne API Model T360/T360M Operation Manual

200

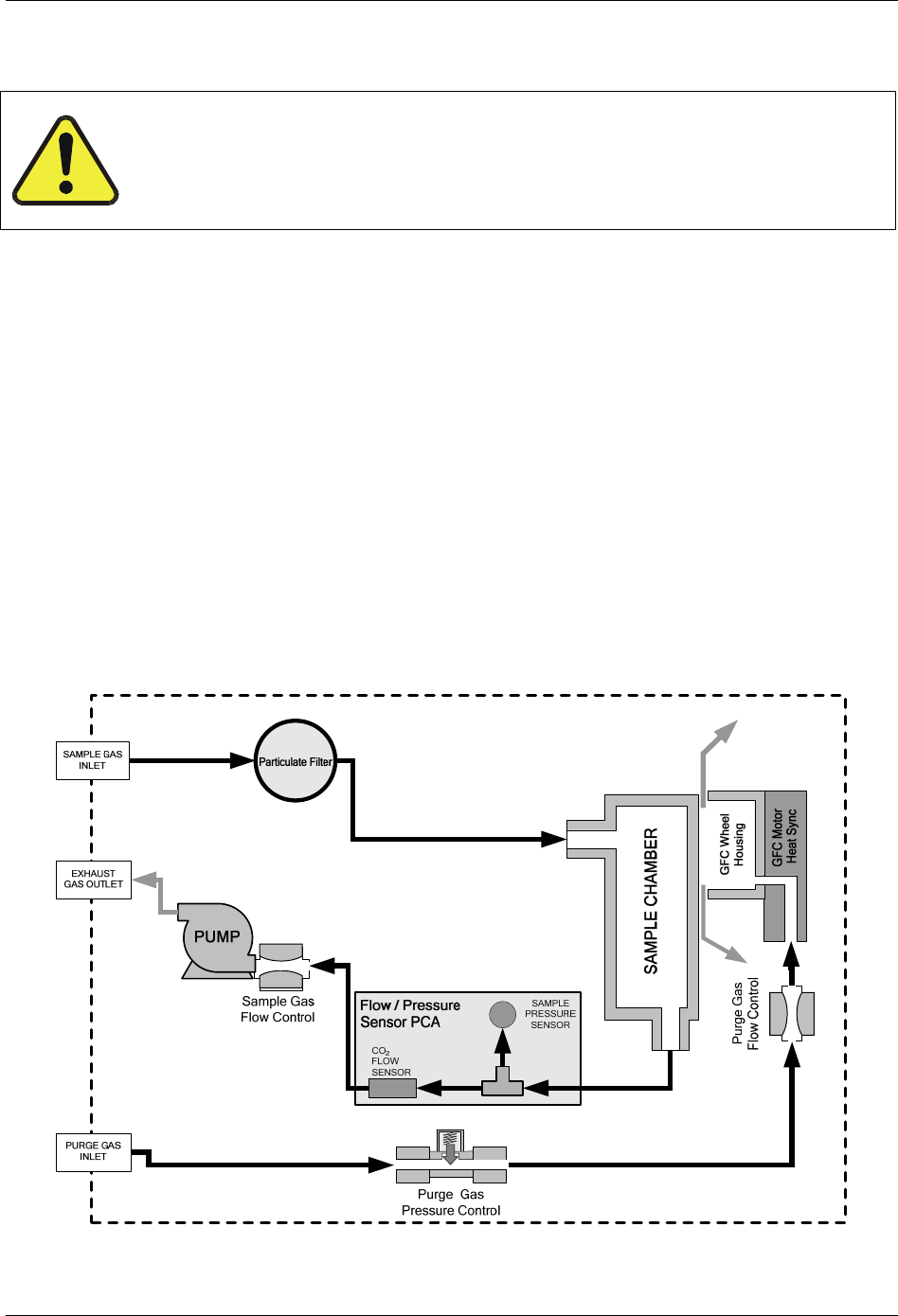

7.3. PNEUMATIC OPERATION

CAUTION

It is important that the sample airflow system is both leak tight and not

pressurized over ambient pressure. Perform regular leak checks (refer to

the maintenance schedule, Table 6-1) on the analyzer as described in the

procedures for correctly performing leak checks in Section 6.3.3.

An internal pump evacuates the sample chamber creating a small vacuum that

draws sample gas into the analyzer. Normally the analyzer is operated with its

inlet near ambient pressure either because the sample is directly drawn at the inlet

or a small vent is installed at the inlet. There are several advantages to this “pull

through” configuration.

By placing the pump down stream from the sample chamber several

problems are avoided.

First the pumping process heats and compresses the sample air

complicating the measurement process.

Additionally, certain physical parts of the pump itself are made of materials

that might chemically react with the sample gas.

Finally, in certain applications where the concentration of the target gas

might be high enough to be hazardous, maintaining a negative gas pressure

relative to ambient means that should a minor leak occur, no sample gas will

be pumped into the atmosphere surrounding analyzer.

7.3.1. Sample Gas Flow

Figure 7-8: Internal Pneumatic Flow – Basic Configuration

07272B DCN6552