3

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, personal

injury, or loss of life. Refer to the User’s Information

Manual provided with this unit for more details.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

What to do if you smell gas:

1. DO NOT try to light any appliance.

2. DO NOT touch any electrical switch, or use any

phone in your building.

3.IMMEDIATELY call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

4. If you cannot reach your gas supplier, call the fire

department.

!

WARNING

GENERAL

This publication contains Start−Up, Controls, Operation, Service,

and Troubleshooting information for the 48/50PG and 48/50PM

rooftop units. (See Table 1.) These units are equipped with

ComfortLink controls version 5.X or higher and use Puron

refrigerant. The specific base unit installation instructions and/or

wiring label diagram may also be required in conjunction with this

book as a guide to a specific unit on the roof. All the units in table

1 are Constant Volume (CV) units that provide stand−alone or

network operation.

Table 1 – Rooftop Units

MODEL SIZE NOMINAL TONS

48/50PG

03 2

04 3

05 4

06 5

07 6

08 7.5

09 8.5

12 10

14 12.5

48/50PM

16 15

20 18

24 20

28

25

BASIC CONTROL USAGE

ComfortLink Control

The ComfortLink control is a comprehensive unit-management

system. The control system is easy to access, configure, diagnose

and troubleshoot.

The ComfortLink control is fully communicating and cable-ready

for connection to the Carrier Comfort Network (CCN) building

management system. The control provides high-speed

communications for remote monitoring via the Internet. Multiple

units can be linked together (and to other ComfortLink control

equipped units) using a 3-wire communication bus.

The ComfortLink control system is easy to access through the use

of a unit-mounted display module. There is no need to bring a

separate computer to this unit for start-up. Access to control menus

is simplified by the ability to quickly select from 11 menus. A

scrolling readout provides detailed explanations of control

information. Only four, large, easy-to-use buttons are required to

maneuver through the entire controls menu. The display readout is

designed to be visible even in bright sunlight.

For added service flexibility, an accessory hand-held Navigator

module is also available. This portable device has an extended

communication cable that can be plugged into the unit’s

communication network at the main control box. The Navigator

display provides the same menu structure, control access and

display data as is available at the unit-mounted Scrolling Marquee

display.

Run Status

Service Test

Temperature

Pressures

Setpoints

Inputs

Outputs

Configuration

Time Clock

Operating Modes

Alarms

Alarm Status

ENTER

MODE

ESCAPE

C06320

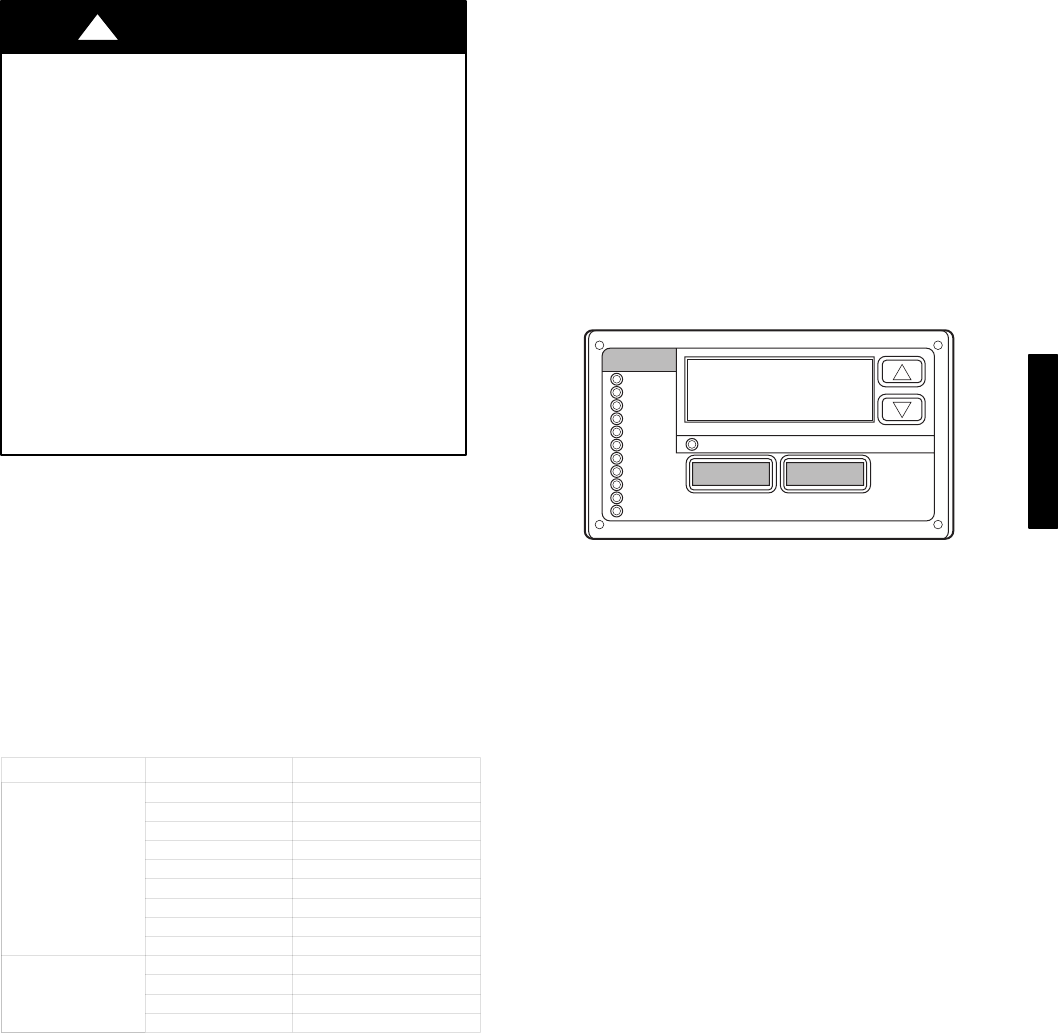

Fig. 1 − Scrolling Marquee

Scrolling Marquee

This device is the keypad interface used to access the control

information, read sensor values, and test the unit. The Scrolling

Marquee is located in the main control box and is standard on all

units. The Scrolling Marquee display is a 4-key, 4-character,

16-segment LED (light-emitting diode) display module. The

display also contains an Alarm Status LED. (See Fig. 1.)

The display is easy to operate using 4 buttons and a group of 11

LEDs that indicate the following menu structures:

Run Status

Service Test

Temperatures

Pressures

Set points

Inputs

Outputs

Configuration

Timeclock

Operating Modes

Alarms

Through the Scrolling Marquee, the user can access all of the

inputs and outputs to check on their values and status, configure

operating parameters plus evaluate the current decision status for

operating modes. The control also includes an alarm history which

can be accessed from the display. In addition, through the Scrolling

Marquee, the user can access a built-in test routine that can be used

at start-up commissioning and to diagnose operational problems

with the unit. (See Table 2.)

48/50PG and PM