Operation 6-21MN1928

6.7 Servo axis - eliminating steady-state errors

In systems where precise positioning accuracy is required, it is often necessary to position

within one encoder count. Proportional gain, KPROP, is not normally able to achieve this

because a very small following error will only produce a small demand for the drive which may

not be enough to overcome mechanical friction (this is particularly true in current controlled

systems). This error can be overcome by applying integral gain. The integral gain, KINT,

works by accumulating following error over time to produce a demand sufficient to move the

motor into the required position with zero following error.

KINT can therefore overcome errors caused by gravitational effects such as vertically moving

linear axes. With current controlled drives a non-zero demand output is required to hold the

load in the correct position, to achieve zero following error .

Care is required when setting KINT since a high value will cause instability during moves.

A typical value for KINT would be 0.1. The effect of KINT should also be limited by setting the

integration limit, KINTLIMIT, to the smallest possible value that is sufficient to overcome friction

or static loads, for example 5. This will limit the contribution of the integral term to 5% of the full

demand output range.

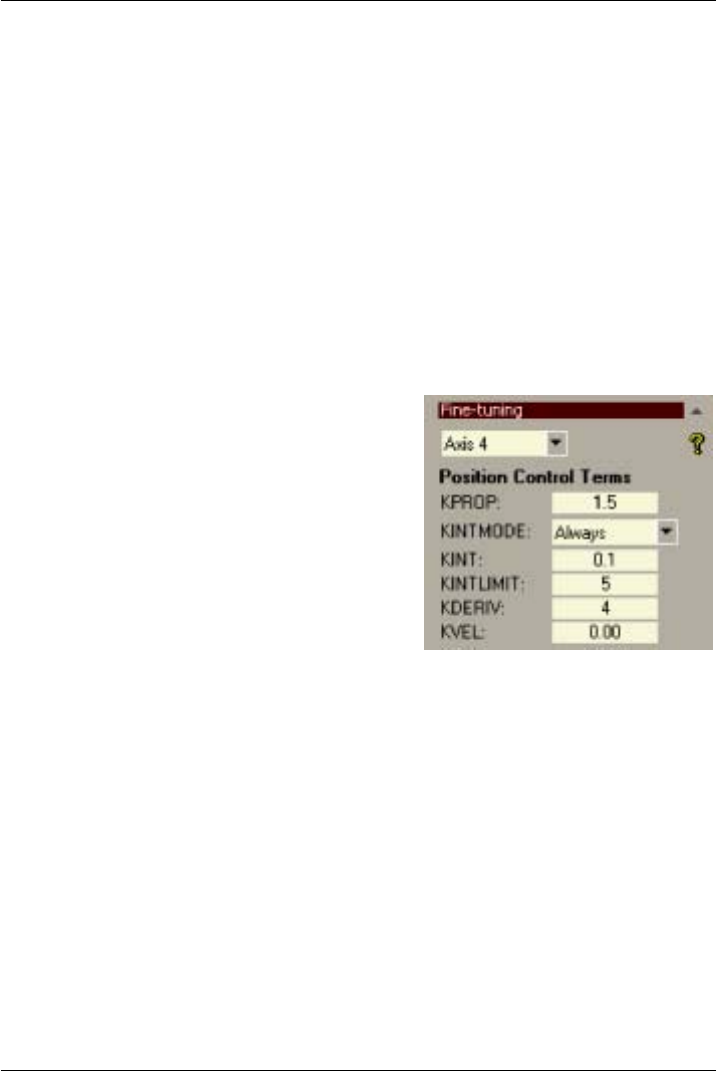

1. Click in the KINT box and ent er a small

starting value, for example 0.1.

2. Click in the KINTLIMIT box and enter a value

of 5.

With NextMove ES, the action of KINT and KINTLIMIT can be set to operate in various modes:

H Never - the KINT term is never applied

H Always - the KINT term is always applied

H Smart - the KINT term is only applied when the demand speed is zero or constant.

H Steady State - the KINT term is only applied when the demand speed is zero.

This function can be selected using the KINTMODE drop down box.