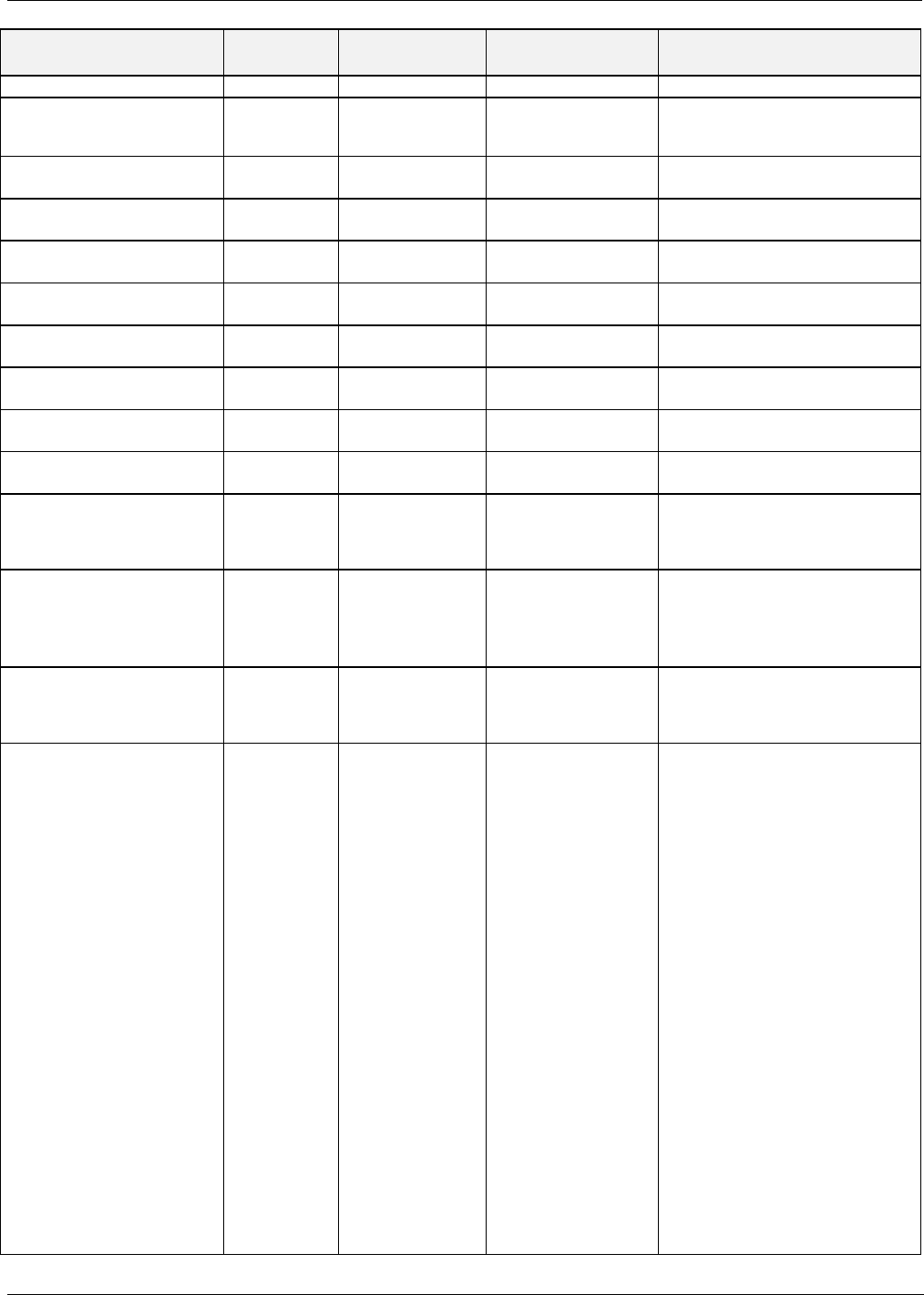

Model 360E Instruction Manual APPENDIX A-2: Setup Variables For Serial I/O, Revision G.4

SETUP VARIABLE

NUMERIC

UNITS

DEFAULT

VALUE

VALUE RANGE DESCRIPTION

period.

WHEEL_PROP 1/ºC 1 0–100

Wheel temperature PID proportional

coefficient. Proportional band is the

reciprocal of this setting.

WHEEL_INTEG — 0.035 0–100

Wheel temperature PID integral

coefficient.

WHEEL_DERIV — 2 0–100

Wheel temperature PID derivative

coefficient.

O2_CELL_CYCLE

5

Seconds 10 0.5–30

O

2

cell temperature control cycle

period.

O2_CELL_PROP

5

— 1 0–10

O

2

cell PID temperature control

proportional coefficient.

O2_CELL_INTEG

5

— 0.1 0–10

O

2

cell PID temperature control

integral coefficient.

O2_CELL_DERIV

5

— 0 (disabled) 0–10

O

2

cell PID temperature control

derivative coefficient.

TPC_ENABLE — ON OFF, ON

ON enables temperature/ pressure

compensation; OFF disables it.

CONC_LIN_ENABLE — ON OFF, ON

ON enables concentration

linearization; OFF disables it.

SERIAL_NUMBER — “00000000 ”

1

Any character in the

allowed character set.

Up to 100 characters

long.

Unique serial number for instrument.

DISP_INTENSITY — HIGH

1

HIGH,

MED,

LOW,

DIM

Front panel display intensity.

I2C_RESET_ENABLE — ON OFF, ON

ON enables automatic reset of the

I

2

C bus in the event of

communication failures; OFF

disables automatic reset.

CLOCK_FORMAT —

“TIME=%H:%M:%S

”

Any character in the

allowed character set.

Up to 100 characters

long.

Time-of-day clock format flags.

Enclose value in double quotes (")

when setting from the RS-232

interface.

“%a” = Abbreviated weekday name.

“%b” = Abbreviated month name.

“%d” = Day of month as decimal

number (01 – 31).

“%H” = Hour in 24-hour format (00 –

23).

“%I” = Hour in 12-hour format (01 –

12).

“%j” = Day of year as decimal

number (001 – 366).

“%m” = Month as decimal number

(01 – 12).

“%M” = Minute as decimal number

(00 – 59).

“%p” = A.M./P.M. indicator for 12-

hour clock.

“%S” = Second as decimal number

(00 – 59).

“%w” = Weekday as decimal number

(0 – 6; Sunday is 0).

“%y” = Year without century, as

05233 Rev G.4 A-21