TROUBLESHOOTING & REPAIR PROCEDURES Model 360E Instruction Manual

11.2. Gas Flow Problems

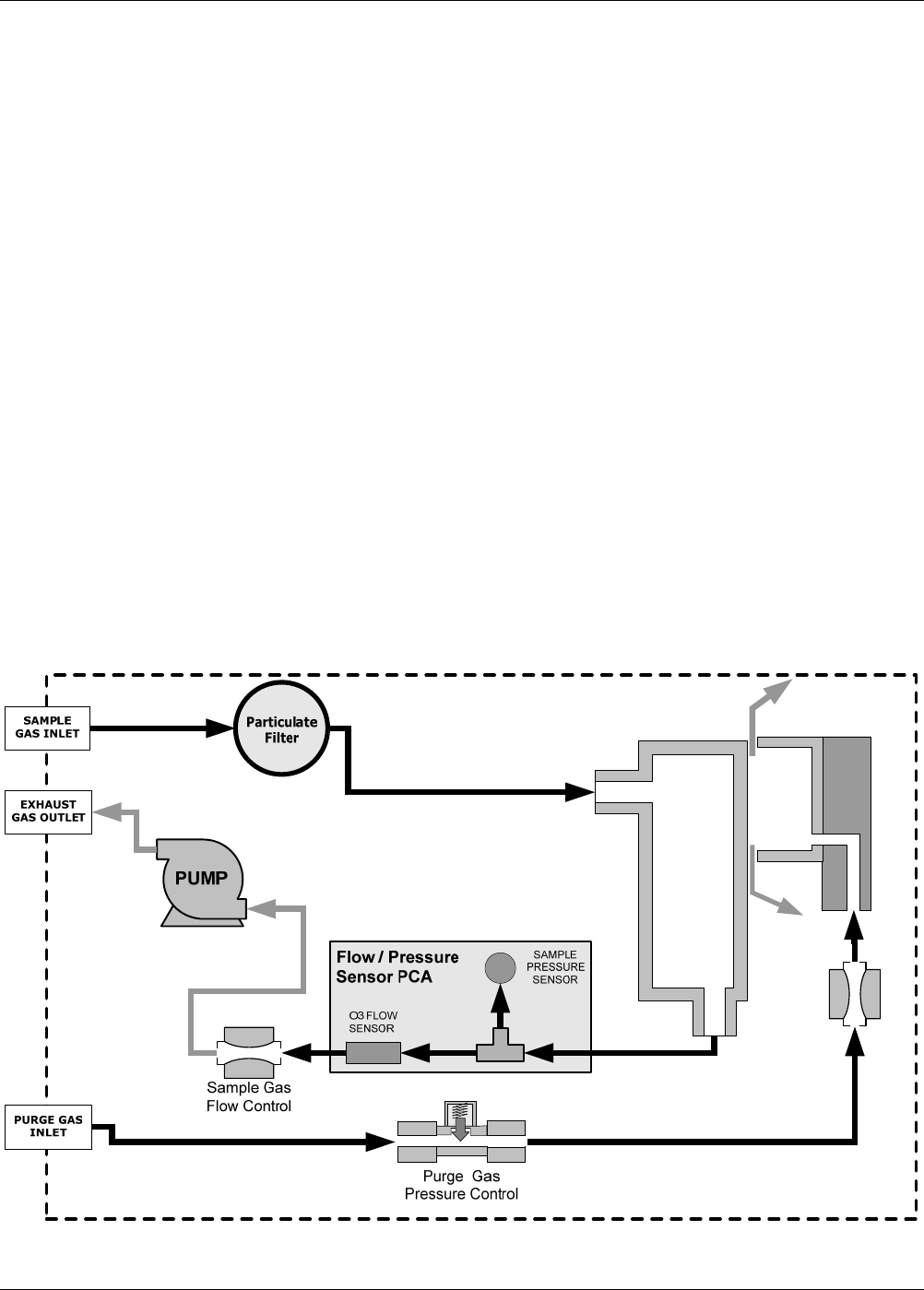

The M360E has two main gas flow path, the sample gas flow path and the GFC purge gas flow path. Both are

controlled by a critical flow orifice. Only the sample gas path is measured and reported. When the IZS or

zero/span valve options are installed, there are several subsidiary paths but none of those are displayed on the

front panel or stored by the iDAS.

With the O

2

sensor option installed, third gas flow controlled with a critical flow orifice is added, but this flow is

not measured or reported.

In general, flow problems can be divided into three categories:

Flow is too high

Flow is greater than zero, but is too low, and/or unstable

Flow is zero (no flow)

When troubleshooting flow problems, it is crucial to confirm the actual flow rate without relying on the analyzer’s

flow display. The use of an independent, external flow meter to perform a flow check as described in Section

9.3.4 is essential. If this test shows the flow to be correct, check the pressure sensors as described in Section

11.5.6.5.

The flow diagrams found in a variety of locations within this manual depicting the M360E in its standard

configuration and with options installed can help in trouble-shooting flow problems. For your convenience they

are colleted here.

11.2.1. M360E Internal Gas Flow Diagrams

GFC Wheel

Housing

SAMPLE CHAMBER

GFC Motor

Heat Sync

Purge Gas

Flow Control

Figure 11-7: M360E – Basic Internal Gas Flow

200 05232 Rev B3