TROUBLESHOOTING & REPAIR PROCEDURES Model 360E Instruction Manual

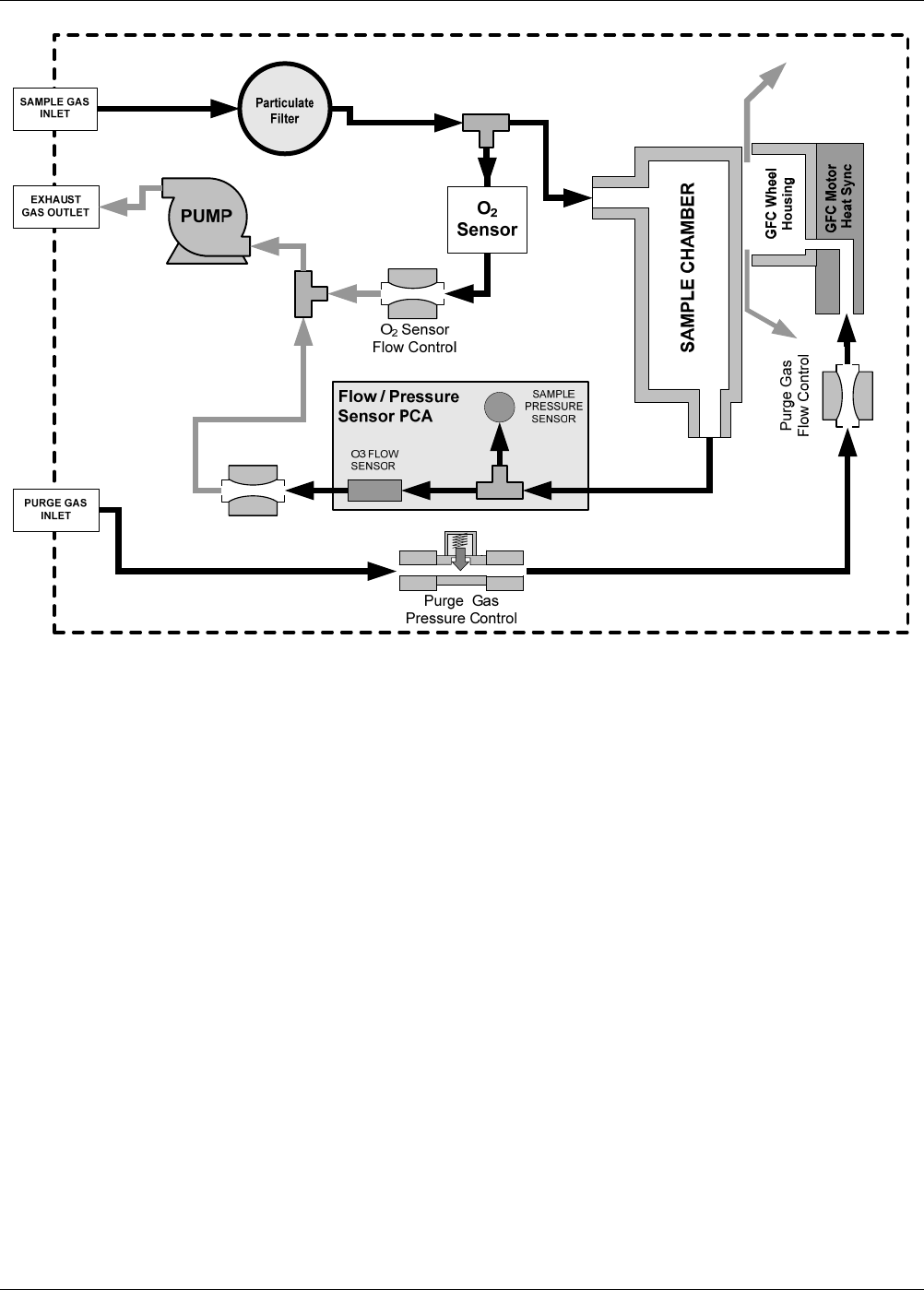

Figure 11.9: M360E – Internal Pneumatics with O

2

Sensor Option 65

11.2.2. Typical Sample Gas Flow Problems

11.2.2.1. Flow is Zero

The unit displays a SAMPLE FLOW warning message on the front panel display or the SAMPLE FLOW test

function reports a zero or very low flow rate.

Confirm that the sample pump is operating (turning). If not, use an AC voltmeter to make sure that power is

being supplied to the pump. If no power is present at the electrical leads of the pump.

1. If AC power is being supplied to the pump, but it is not turning, replace the pump.

2. If the pump is operating but the unit reports no gas flow, perform a flow check as described in Section

9.3.4.

3. If no independent flow meter is available:

Disconnect the gas lines from both the sample inlet and the exhaust outlet on the rear panel of the

instrument.

Make sure that the unit is in basic SAMPLE Mode.

Place a finger over an Exhaust outlet on the rear panel of the instrument.

If gas is flowing through the analyzer, you will feel pulses of air being expelled from the Exhaust

outlet.

202 05232 Rev B3