52

This appliance uses a single cylindrical burner installed vertically

into the cavity located in the center of the primary heat

exchanger. There is a unique burner for each one of the three

models.

Burners may NOT be changed between different Btu/hr input

models. The burner consists of a round mounting flange welded

to a mixing tube. The top side of the mixing tube provides the

transition which mounts the discharge from the combustion air

blower into the burner. The bottom side of the mixing tube is

attached to a stainless steel perforated sleeve. This stainless steel

sleeve is covered with a loose fitting, woven alloy

ma te ri al that forms the burner port sur face. The woven burner

port material is called Alcromesh which is a unique alloy of iron,

chrome, aluminum and several rare earth metals. This alloy is

designed to operate stress free as a burner port surface. The

Alcromesh burner port surface can sustain op er a tion from a blue

flame down to infrared conditions as the burner input varies.

Internally, the burner has a cone and distribution baffles to

balance the air/gas mixture over the surface of the burner. The

burner mounting flange provides a flame view port and the

mounting point for the hot surface igniter. The hot surface igniter

is removable from the burner mounting flange without removing

the burner assembly from the heat exchanger.

NOTE:

An index mark is provided on the burner flange to ensure

proper ori en ta tion when removing and reinstalling the

burner. A properly indexed burner will ensure correct

location of the com bus tion air blower and adequate

clearances from other components in the top jacket

chamber.

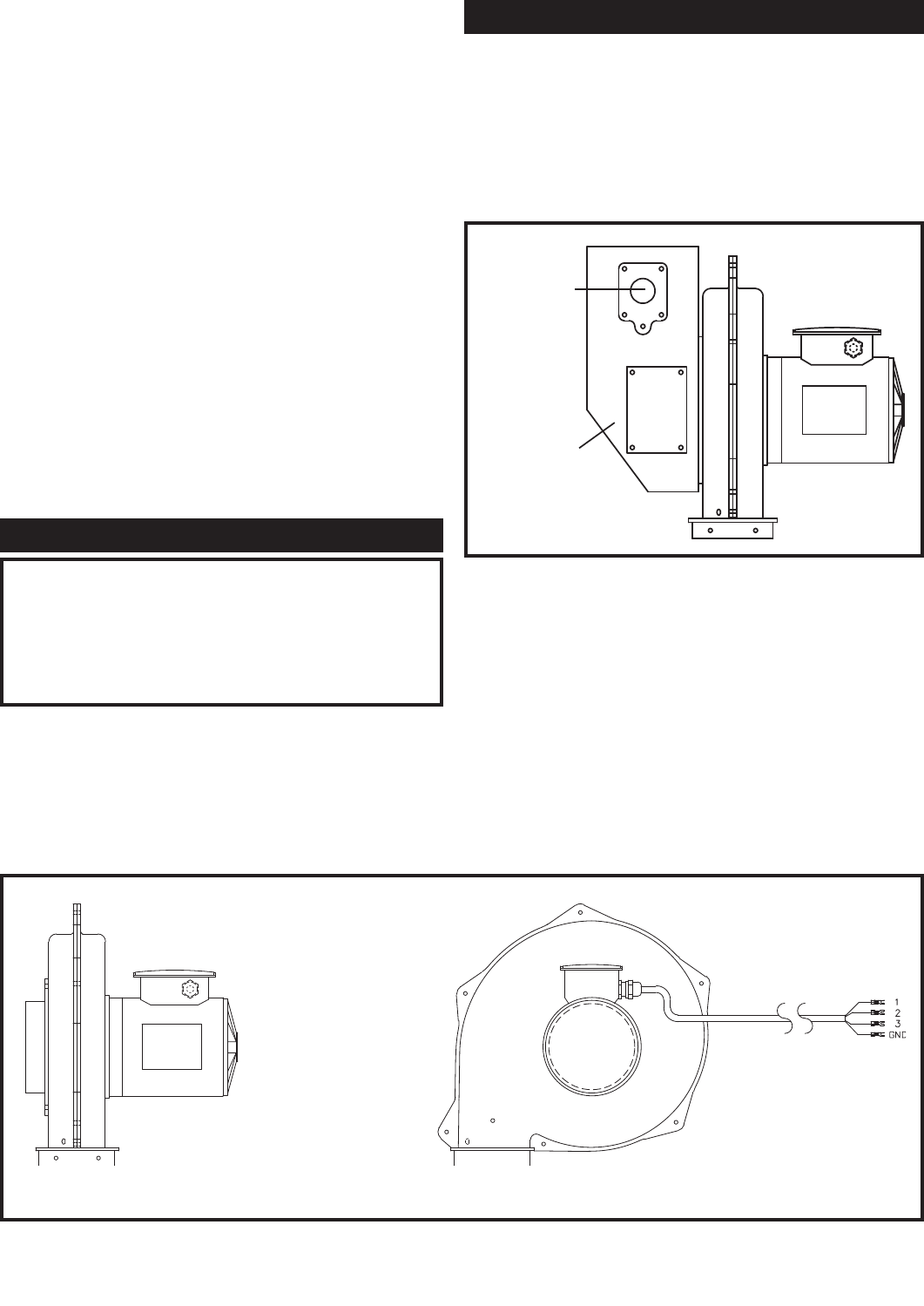

FIG. 68 Combustion Air Blower

The burner is designed to operate from 100% of rated input down

to 25% of rated input in normal operation. Burn er operation at

input rates of less than 50% may include operation in the infrared

state. At input rates firing above 50%, there may be some slight

infrared visible on the tips of the woven burner port material.

This is normal burner operation.

COMBUSTION AIR BLOWER

ORIFICE

MOUNTING

TRANSITION

CHAMBER

FIG. 69 Combustion Air Blower and Transition Chamber

A sealed transition chamber is mounted on the inlet to the

combustion air blower. This chamber contains the gas orifice and

a sensing point for op er a tion of the ratio gas valve. Inside the

transition chamber, at the inlet to the combustion air blower there

is a filter to prevent particulate matter and small foreign objects

from entering the blower and burner. This filter should be checked

and cleaned on a six month interval or more often in a con tam inated

environment. An inspection port is provided on the side of the

transition chamber to allow access to the internal filter for

inspection and cleaning. If cleaning is required, remove the filter

through the inspection port and clean with soapy water or

compressed air.

This appliance uses a sealed air blower to provide combustion air

for the burn er and operate the Category IV venting system. The

blower assembly consists of a sealed housing and blower wheel

constructed from cast aluminum. The blower is operated by a fully

en closed 230 VAC, 3 Phase electric motor. This motor has a 3/4 HP

rating on the 1,500,000 Btu/hr model and a 1 HP rat ing on the

1,700,000 and 2,000,000 Btu/hr models. The blower housing and

motor assembly is fully sealed and CANNOT be field serviced.