7

All dimensions based on net free area in square inches. Metal

louvers or screens reduce the free area of a com bus tion air opening

a minimum of ap prox i mate ly 25%. Check with louver

manufacturers for exact net free area of louvers. Where two

openings are provided, one must be within 12" (30 cm) of the

ceiling and one must be within 12" (30 cm) of the floor of the

mechanical room. Each opening must have net free area as

specified in Table - B. Single openings shall commence within 12"

(30 cm) of the ceiling.

The combustion air supply must be com plete ly free of any

flammable vapors that may ignite or chemical fumes which may

be corrosive to the appliance. Common corrosive chemical fumes

which must be avoided are fluorocarbons and other halogenated

compounds, most commonly present as refrigerants or solvents,

such as Freon, trichlorethylene, perchlorethylene, chlorine, etc.

These chemicals, when burned, form acids which quickly attack

the heat exchanger finned tubes, headers, flue collectors, and the

vent system. The result is improper combustion and a non-

warrantable, premature appliance failure.

These chemicals, when burned form acids which quickly attack the

boiler tubes, tube sheets, flue collectors, and the ap pli ance stack.

The result is improper combustion and a non-warrantable, pre ma -

ture failure of the appliance.

EXHAUST FANS: Any fan or equipment which exhausts air from

the equipment room may deplete the combustion air supply and/or

cause a downdraft in the venting system. Spillage of flue prod ucts

from the venting system into an occupied living space can cause a

very hazardous condition that must be im me di ate ly corrected. If a

fan is used to supply combustion air to the equipment room, the

installer must make sure that it does not cause drafts that could lead

to nuisance operational problems with the appliance.

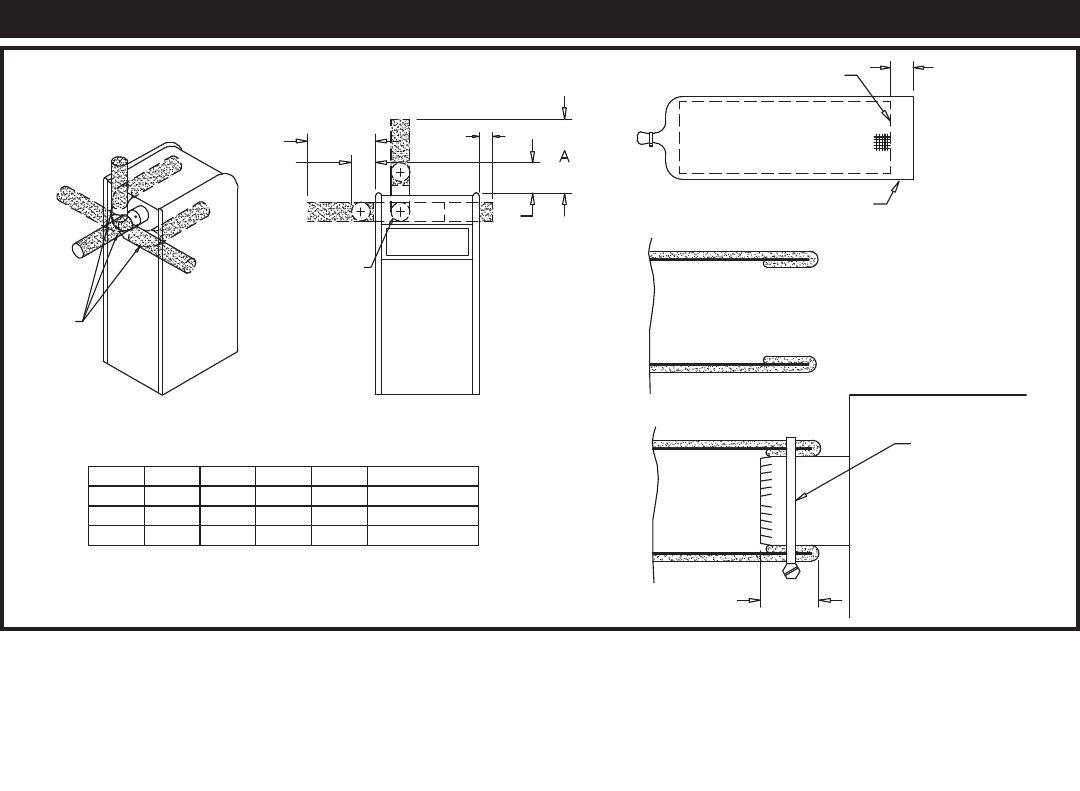

A construction air filter is installed on the ap pli ance as shipped.

The filter assembly is installed on the combustion air inlet located

at the rear of the appliance. The filter assembly slips over the air

inlet collar and is secured in place with the clamp provided with

the filter. If limited space is available at the rear of the appliance,

field supplied elbows may be used to mount the filter in the

alternate positions shown in the illustration. This filter is For

Temporary Use Only on an appliance that must be operated for

temporary heat or hot water when a building is under construction.

The filter will provide a temporary means to remove airborne dust,

dirt and particulate matter generated by construction. The filter

prevents airborne particulate contaminants from being drawn into

the burner with the combustion air. The filter can be cleaned

routinely during construction if necessary. Remove the filter to

clean. Wash the filter with water. A flow of water from the inside

to the outside should remove most particle matter. Allow the filter

to dry before reinstalling. Unfiltered com bus tion air from a

construction site can contain con tam i nants that will collect in the

burner reducing the firing rate. A burner that becomes clogged with

airborne particulate contaminants must be removed and cleaned to

restore proper operation to the burner. Sustained operation of an

appliance with a clogged burner may result in nuisance operational

prob lems, bad combustion and non-warrantable component failures.

CONSTRUCTION AIR FILTER

9.000

ELBOW(S)

NOT

PROVIDED

CABINET AIR

INLET OPENING

D

E

C

B

EDGE OF SCREEN

2"

MEDIA OVERLAP

FOLD OVERLAP AROUND

EDGE OF SCREEN AS

SHOWN.

PUSH FILTER ONTO AIR

INLET AND FASTEN WITH

CLAMP AS SHOWN.

BAND CLAMP

2"

MODEL

A

B

C

D E REAR

2.0 19.750

12.250 4.875

15.000

24.000

1.7

1.5

19.250

18.750

10.750

9.250

4.375

3.875

6.000

7.500

14.000

24.000

14.500

24.000

FRONT

REAR

FIG. 9 Construction Air Filter