38

Excel 10 Boiler Interface Controller - The boiler interface

control ler for this appliance is based on the Excel 10 controller

platform with unique software customized for op er a tion of the

Lochinvar Intelli-Fin. The Excel 10 is also compatible with

LonWorks

®

building management systems. All of the appliances’

internal safety, operating and ignition controls in ter face with the

Excel 10 controller. Local communication, programming and a

digital display of the appliance func tions and operating

conditions are accessible through a Command Display. The

Command Display is mounted on the front control panel of the

appliance as shipped from the manufacturer. If mul ti ple Intelli-Fin

appliances are to be installed in a single application, see

“Multiple Appliance Installations” for information on interfacing,

sequencing and display of multiple Intelli-Fin appliances.

NOTE:

A single Command Display is shipped for each job site

installation with up to 16 Intelli-Fin appliances. A

single Command Display is used to display and access

the operating conditions of up to 16 Intelli-Fin

appliances.

The Excel 10 Boiler Interface Control serves as the operating

temperature control to regulate the amount of heat added to the

water system for both heating boilers and potable water heat ers.

Custom software programmed into the Excel 10 will determine

the proper operating profile for your specific application. Ensure

that an Intelli-Fin is properly applied. A unit or dered as a heating

boiler must be ap plied as a heating boiler and a unit ordered as a

potable water heater must be applied as a water heater. The Excel

10 Boiler Interface Control provides on/off control of the gas

supply to the burner, operation of a VFD to control a variable

speed combustion air blower, interface with the ignition control

system, on/off control of the integral circulating pump, operation

of a float ing point bypass valve, control of water temperature set

points, and mon i tor ing of all safety functions. The operation and

status of these and all related functions are displayed on the

Command Display.

The Excel 10 has a single LED located in the middle of the control

module. In normal operation of a boiler equipped with an optional

outdoor reset function, this LED will blink at the rate of one blink

per second. Active alarms will blink this service LED at a faster

than normal rate of two blinks per second to indicate an alarm. The

alarms which are displayed in this manner are: Network

communications failure, sensor failure, hard lockout, water flow

failure, low air, blocked drain, low/high gas pressure, flame failure,

soft lockout, heat mode fail ure, high temperature alarm, and boiler

not operational. A boiler that is not equipped with the outdoor reset

func tion or a water heater will always blink the LED at the faster

rate of approximately two blinks per second. This LED is not to

be used as a di ag nos tic indicator.

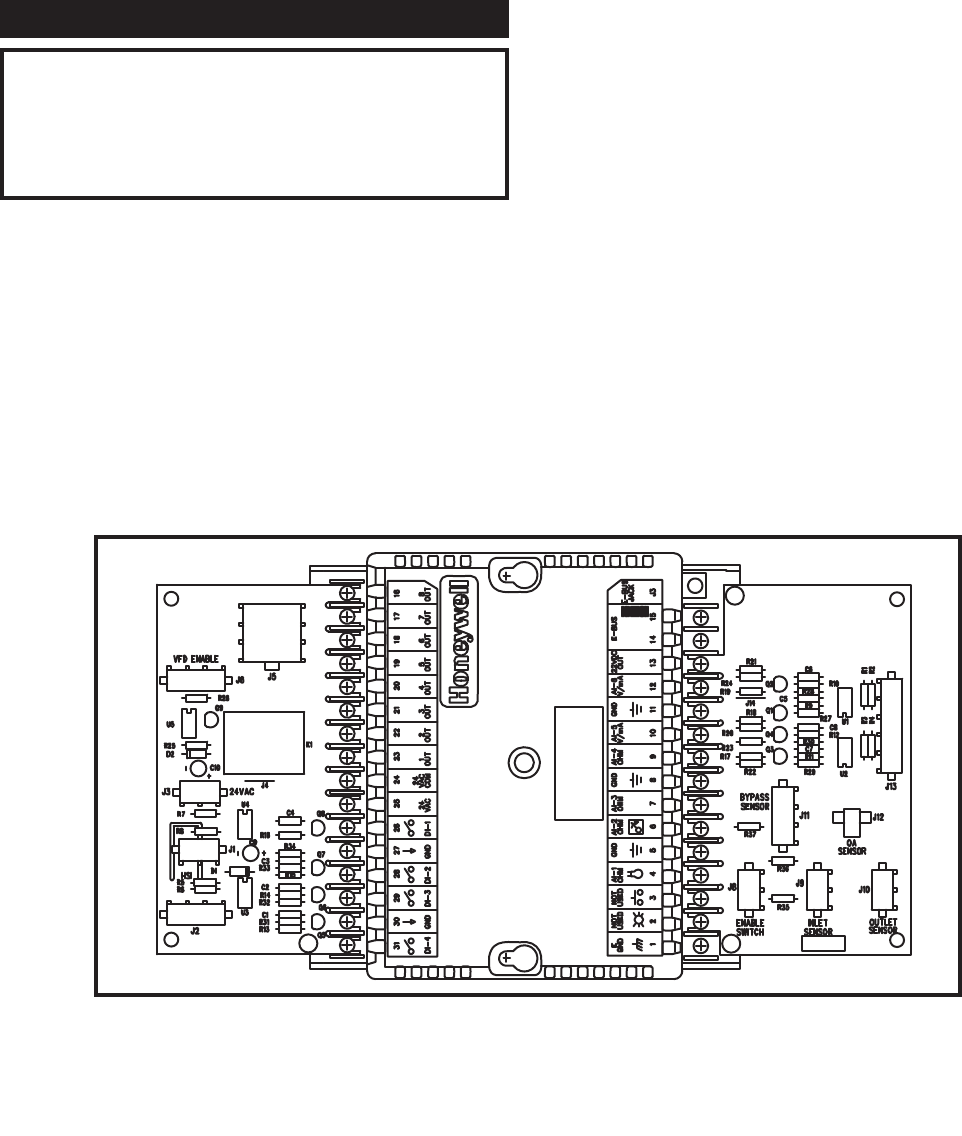

The Excel 10 controller is mounted on the backside of the front

control panel that mounts the Command Display and the Ignition

Control Module. This panel is hinged on the right side so it can be

exposed for viewing and service. All connections from the

appliance safety and operating controls to the Excel 10 are

accomplished with multiple wiring harnesses. Each wiring harness

is connected to unique multiple pin terminations to ensure proper

con nec tion of all components. The multiple termination points are

located on two printed circuit boards mounted on ei ther side of the

Excel 10 controller. Use caution when connecting or dis con necting

wires at the plug in terminals to prevent damage to the printed

circuit boards.

There is a bar code label on the back of the Intelli-Fin near the

terminal connections. This is the Neuron I.D. label which identifies

the exact nu mer i cal sequence applied to the Excel 10 control

installed in the boiler/water heater. This information is required for

the local/remote communication network. The numerical sequence

FIG. 53 Excel 10 Control Module with Circuit Boards and Wire Terminal Connections