37

blower from 25% up to 100% of capacity corresponding to the

same variation in burner input. The output from the Excel 10 to

the variable frequency drive ensures that combustion air and gas

are always supplied in the proper ratio for clean combustion. The

vari able frequency drive is driven to 100% during the pre-purge

portion of the start-up sequence. The variable fre quen cy drive is

then provided a signal to operate at 50% for initial burner ignition.

After main burner ignition is established, the Excel 10 will use the

variable frequency drive to vary the blower speed based on desired

water temperature set point, the variation in actual water

temperature from the de sired set point and the various op er at ing

characteristics programmed into the control’s software.

When removing the variable frequency drive from the appliance,

disconnect the power wires to the combustion air blower at the

terminals on the variable frequency drive. DO NOT disconnect the

power wires at the blower motor. Note the marking of the wires for

proper reinstallation of the three phase power wires to the VFD.

Both the wires and the VFD terminals are marked for proper

location of wire terminals. Incorrect installation of the wires may

reverse rotation of the blower motor resulting in major operational

problems.

CAUTIONƽ

The voltage output from the variable frequency drive to the

combustion air blower is 230 volt 3 phase. Avoid contact

with high voltage wiring.

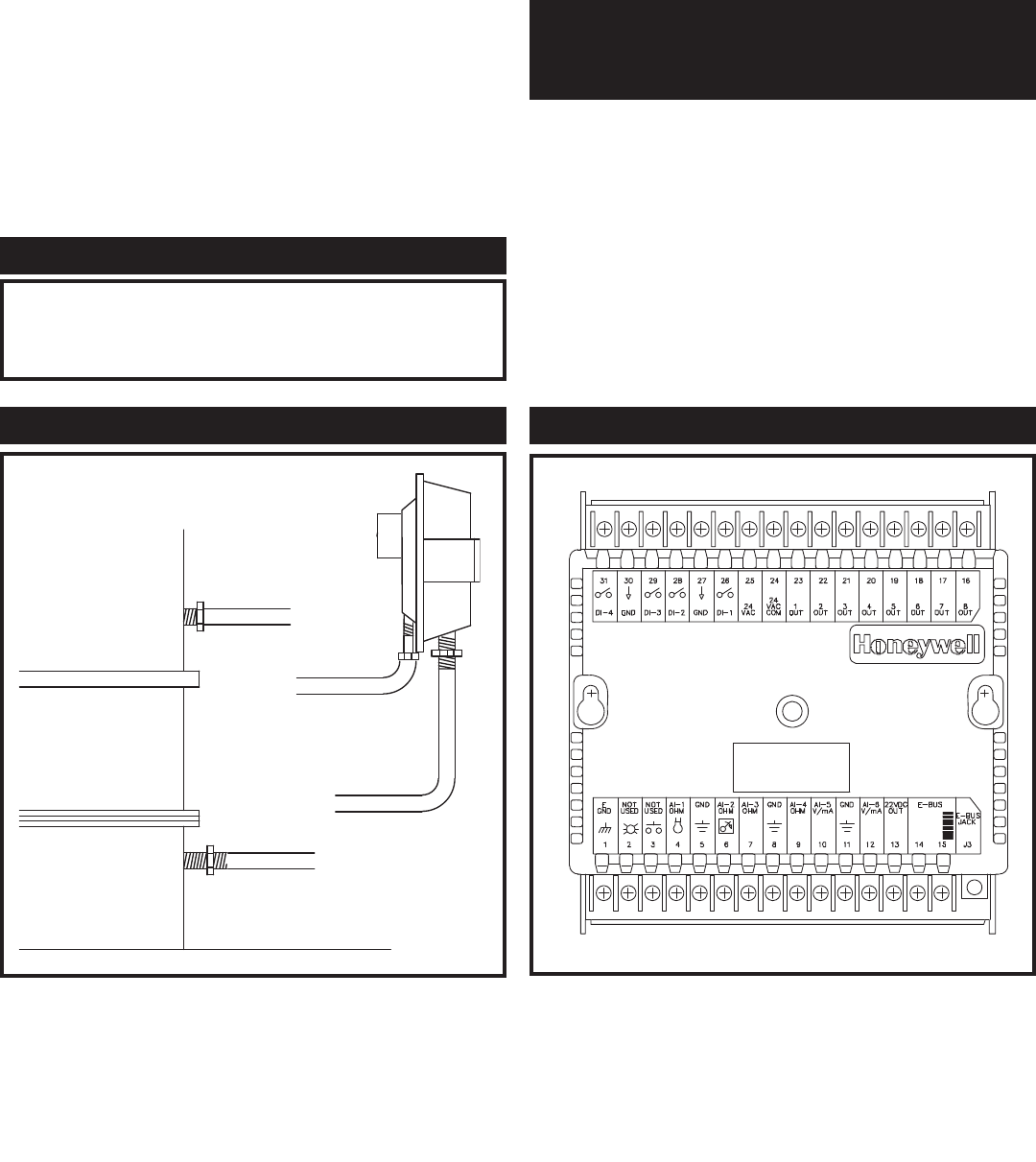

LOW AIR PRESSURE SWITCH

PRESSURE SWITCH

BLOWER

TRANSITION

BURNER

~

~

~

~

~

~

~

~

FIG. 51 Low Air Pressure Switch

FIG. 52 Excel 10 Control Module

EXCEL 10

A differential air pressure switch is used to prove operation of the

com bus tion air blower. The pressure switch sensing points are

installed across the point of pressure drop as the air moves into the

inlet of the burner. This switch measures the same pressure drop

points similar to those used by the ratio gas valve to adjust manifold

gas pressure. Cor rect differential pressure across the sensing points

of the pressure switch proves operation of the combustion air

blower to the Excel 10 control. The Command Display will exhibit

a Status Alarm of LowAirPress and the appliance will shut down

operation when the differential pressure switch detects a sustained

low air condition.

HIGH GAS PRESSURE SWITCH

LOW GAS PRESSURE SWITCH

(Optional)

High and/or low gas pressure switches are available as an option on

this appliance. The high gas pressure switch is used to monitor the

maximum gas supply pressure supplied to the gas train. If gas

pressure exceeds the maximum setting of the pressure switch, the

appliance will shut down and a gas pressure fault will be indicated

in the Command Display. The low gas pressure switch is to

monitor the minimum gas supply pressure supplied to the gas train.

If gas pressure falls below the minimum setting of the pres sure

switch, the appliance will shut down and a gas pressure fault will

be indicated on the Command Display. GasPressFail will be shown

on the Display for either a high or low gas pressure problem.