16

VERTICAL COMBUSTION AIR INLET

FIG. 21 Air Inlet Cap for Rooftop Termination

The air inlet cap for the vertical roof top air inlet is assembled

from com po nents purchased locally. The air inlet cap consist of

two 90° elbows installed at the point of termination for the air

inlet pipe. The first 90° elbow is in stalled on the rooftop at the

highest vertical point of the air inlet pipe and turned horizontal,

the second 90° elbow is installed on the horizontal outlet of the

first elbow and turned down. A 90° elbow and a 90° street elbow

may be used to make this assembly. If a straight piece of pipe is

used be tween the two elbows, it should not ex ceed 6" (150 mm)

in length. The termina tion elbow on the air inlet must be located

a minimum of 12" (0.30 m) above the roof or above normal levels

of snow accumulation.

The point of termination for the com bus tion air inlet cap MUST

be at least 3 feet (0.91 m) below the point of flue gas termination

(vent cap) if it is located within a 10 foot (3.05 m) radius of the

flue outlet. Use care to ensure that the 90° elbow assembly is

properly installed on the air inlet pipe.

The combustion air inlet cap must not be installed closer than

10 feet (3.05 m) from an inside corner of an L-shaped structure.

The termination point of the combustion air inlet cap must be

installed at least one foot (0.30 m) above the roof top and above

normal snow levels.

The combustion air cap assembly used MUST adequately protect

the combustion air inlet from wind and weather.

The combustion air cap and flue gas outlet MUST be located on

the same roof top surface and in the same pressure zone.

Combustion air supplied from outdoors must be free of

contaminants (see Com bus tion and Ventilation Air). To pre vent

recirculation of flue products in to the combustion air inlet, follow

all instructions in this section.

Incorrect installation and/or location of the air inlet cap can allow

the discharge of flue products to be drawn into the combustion

process on the heater. This can result in incomplete combustion

and potentially hazardous levels of carbon monoxide in the flue

products. This will cause operational problems with the heater and

possible spillage of flue products that can cause personal injury,

death or prop er ty damage.

Multiple Vertical Direct Vent Installations

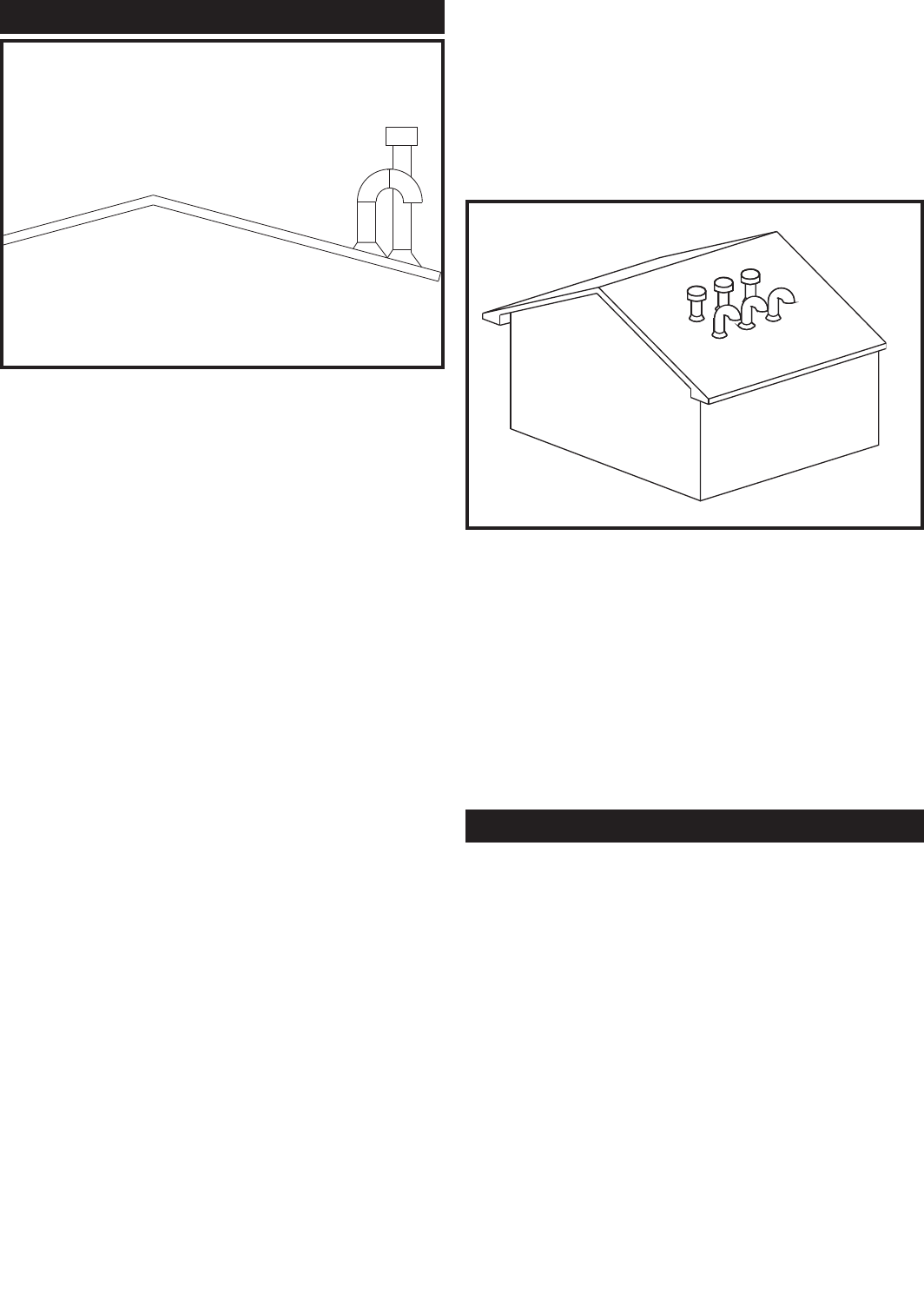

FIG. 22 Multiple Vertical Direct Vent Installations

The combustion air inlet caps for mul ti ple appliance installations

must maintain the minimum 3 foot (0.91 m) clearance below the

closest vertical flue outlet if within 10 feet (3.05 m). Multiple flue

outlet caps may be in stalled side by side and multiple air inlet caps

may be installed side by side but the air inlet must always be at

least 3 feet (0.91 m) below the closest flue outlet if the outlet is

within 10 feet (3.05 m). All clearance and installation requirements

in this sec tion and the applicable portions of the general Category

IV venting section must be maintained on multiple ap pli ance

installations.

For venting flue products horizontally to the outdoors, follow all

re quire ments in the installation instructions for sidewall venting.

Termination point for the flue products must follow the clearance

requirements in the Sidewall Vent Termination section of Category

IV Venting.

A Horizontal Direct Vent System is installed with a Category IV flue

and a separate combustion air pipe to the outdoors. The Direct Vent

system ter mi nates both the flue and air inlet in the same pressure

zone. The flue out let and combustion air intake must both terminate

on the same sidewall.

Follow all requirements in the General Category IV Venting

sections for proper installation and of venting flue prod ucts to the

outdoors with a sidewall termination. All other general

in stal la tion requirements must be followed.

HORIZONTAL DIRECT VENT