53

FILTER ACCESS PLATE

FIG. 70 Cleaning the Internal Combustion Air Blower Inlet

Filter

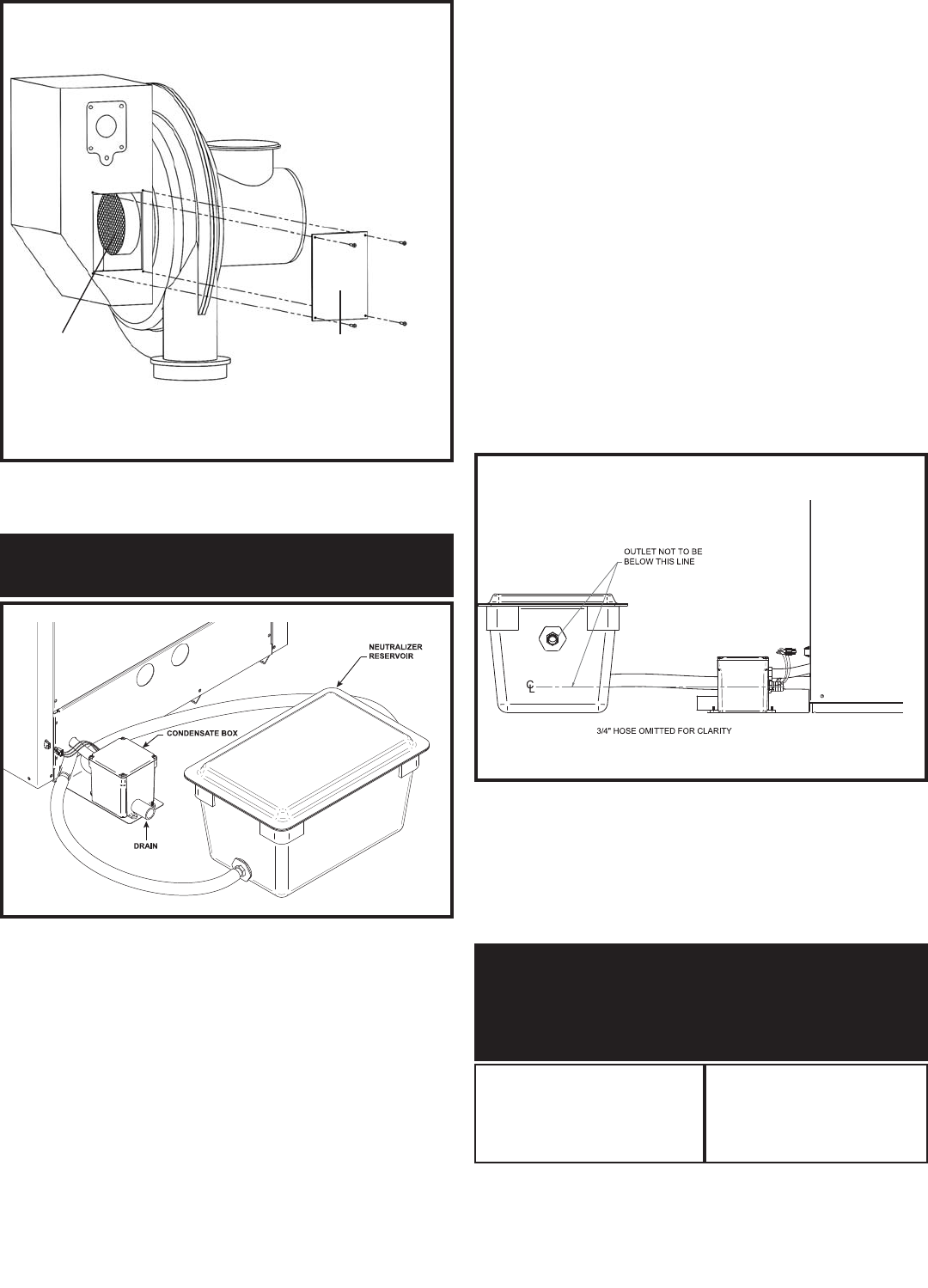

CONDENSATE MANAGEMENT

SYSTEM (Optional)

FIG. 71 Location and Connection of Neutralization Reservoir

This high efficiency appliance may operate as a condensing appliance

for extended periods of time based on return water temperatures.

Condensate occurs when the products of combustion are cooled below

their dew point in the heat transfer process. The liquid con den sate

formed from this high efficiency heat transfer pro cess is mildly acidic.

The con den sate will typically have a pH ranging from 4.0 to 5.0 as it

is discharged from the con den sate drain on the rear of the appliance.

The internal jacket area where the condensate is col lect ed (secondary

heat exchanger) is con struct ed from a spe cial corrosion resistant

stainless steel. All ma te ri als external to the appliance in contact with

the con den sate must be corrosion resistant. This is typically

accomplished by gravity requiring a minimum downward slope of

1/4" per foot to ensure proper flow to the condensate management

system and /or a suitable drain. The neutralizer reservoir MUST

always be mount ed on the same lev el or lower than the bottom of the

appliance cabinet. All con den sate pip ing and con nec tions must be

eas i ly ac ces si ble for rou tine main te nance and inspection. Sufficient

lengths of tubing and barbed connectors are supplied in the kit to allow

the neu tral iz er res er voir to be po si tioned to the right, left or rear of the

appliance.

FIG. 72 Condensate Drain Location On Rear of the

Appliance

Operation of the appliance in a full condensing mode for extended

periods of time may produce flue gas condensate in amounts up to

the following volume:

TABLE - BB

Approximate Maximum

Condensate Volumes

Model/Input Btu/hr Gallons Per Hour

1,500,000

_______________________

1,700,000

_______________________

2,000,000

7.3

_______________________

8.3

_______________________

9.7