5

NOTE

Clearances from combustible construction are noted on the

appliance rating plate.

Maintain minimum specified clearances for adequate operation.

All in stal la tions must allow sufficient space for servicing the vent

connections, water pipe connections, integral circulating pump,

bypass piping and other auxiliary equipment, as well as the

appliance. The clearance labels on each appliance note the same

service and combustible clearance requirements as shown in the

clearances from combustion construction table.

Multiple appliances may be installed in a modular boiler or water

heater in stal la tion. Multiple appliances may be installed side by

side with no clear ance between adjacent appliances because this

appliance is approved for zero clearance from combustible sur fac -

es and no service access is required from the sides.

Consult the venting section of the manual for specific installation

in struc tions for the appropriate type of venting system that you will

be using. Direct Vent and Intelli-Vent venting systems require

installation with Category IV flue pipe, sealed air inlet pipe and air

inlet caps, which must meet the manufacturer’s specifications.

COMBUSTION AND VENTILATION

AIR REQUIREMENTS FOR

APPLIANCES DRAWING AIR FROM

THE EQUIPMENT ROOM

Provisions for combustion and ven ti la tion air must be in accordance

with Section 5.3, Air for Combustion and Ventilation, of the latest

edition of the National Fuel Gas Code, ANSI Z223.1, in Canada,

the latest edition of CAN/CGA Standard B149 Installation Code

for Gas Burning Appliances and Equip ment, or applicable

provisions of the local building codes.

The equipment room MUST be provided with properly sized

openings to assure adequate combustion air and proper ventilation

when the unit is installed with a basic Category IV venting system.

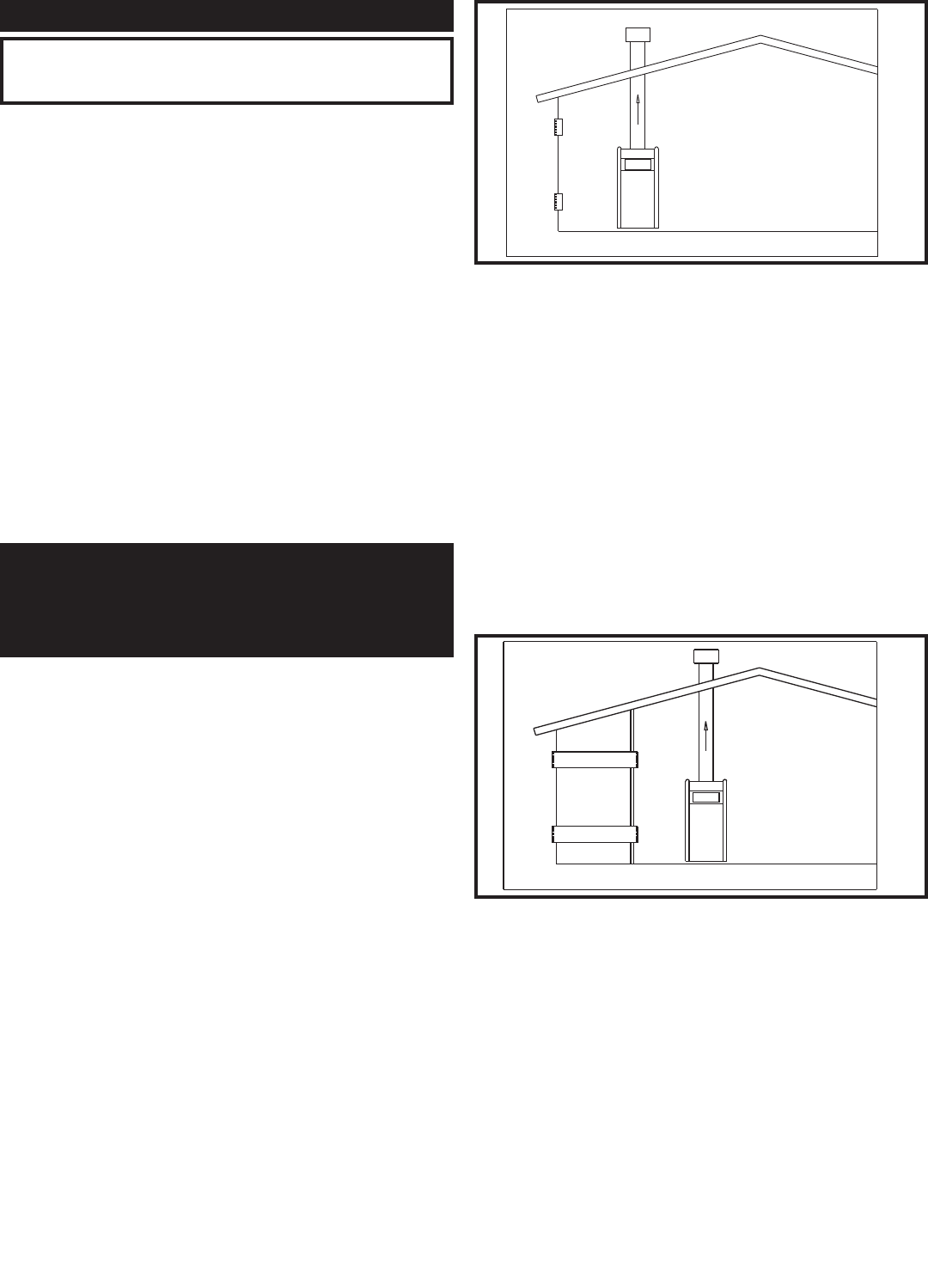

FIG. 5 Combustion Air Direct from Outside

1. If air is taken directly from outside the building

with no duct, provide two permanent openings:

a. Combustion air opening, with a min i mum free

area of one square inch per 4000 Btu input

(5.5 cm

2

per kW). This opening must be located

within 12" (30cm) of the bottom of the

enclosure.

b. Ventilation air opening, with a minimum free

area of one square inch per 4000 Btu input

(5.5 cm

2

per kW). This opening must be located

within 12" (30 cm) of the top of the enclosure.

FIG. 6 Combustion Air Through Ducts

2. If combustion and ventilation air is taken from the outdoors

using a duct to deliver the air to the mechanical room, each of

the two openings should be sized based on a minimum free

area of one square inch per 2000 Btu (11 cm2 per kW) of input.