33

RELIEF VALVE

This unit is supplied with a relief valve(s) sized in accordance with

ASME Boiler and Pressure Vessel Code, Sec tion IV (“Heating

Boilers”). The re lief valve(s) is installed in the

ver ti cal position and mounted in the hot water outlet. No valve is

to be placed between the relief valve, and the unit. To prevent water

damage, the discharge from the relief valve shall be piped to a

suitable floor drain for disposal when relief occurs. No reducing

cou plings or other restrictions shall be installed in the discharge

line. The discharge line shall allow complete drainage of the valve

and line. Relief valves should be manually operated at least once

a year.

CAUTIONƽ

Avoid contact with hot discharge water.

NOTE:

The gas train and controls assembly provided on this unit

have been tested under the applicable American National

Standard to meet minimum safety and performance criteria

such as safe lighting, combustion and safety shutdown

operation.

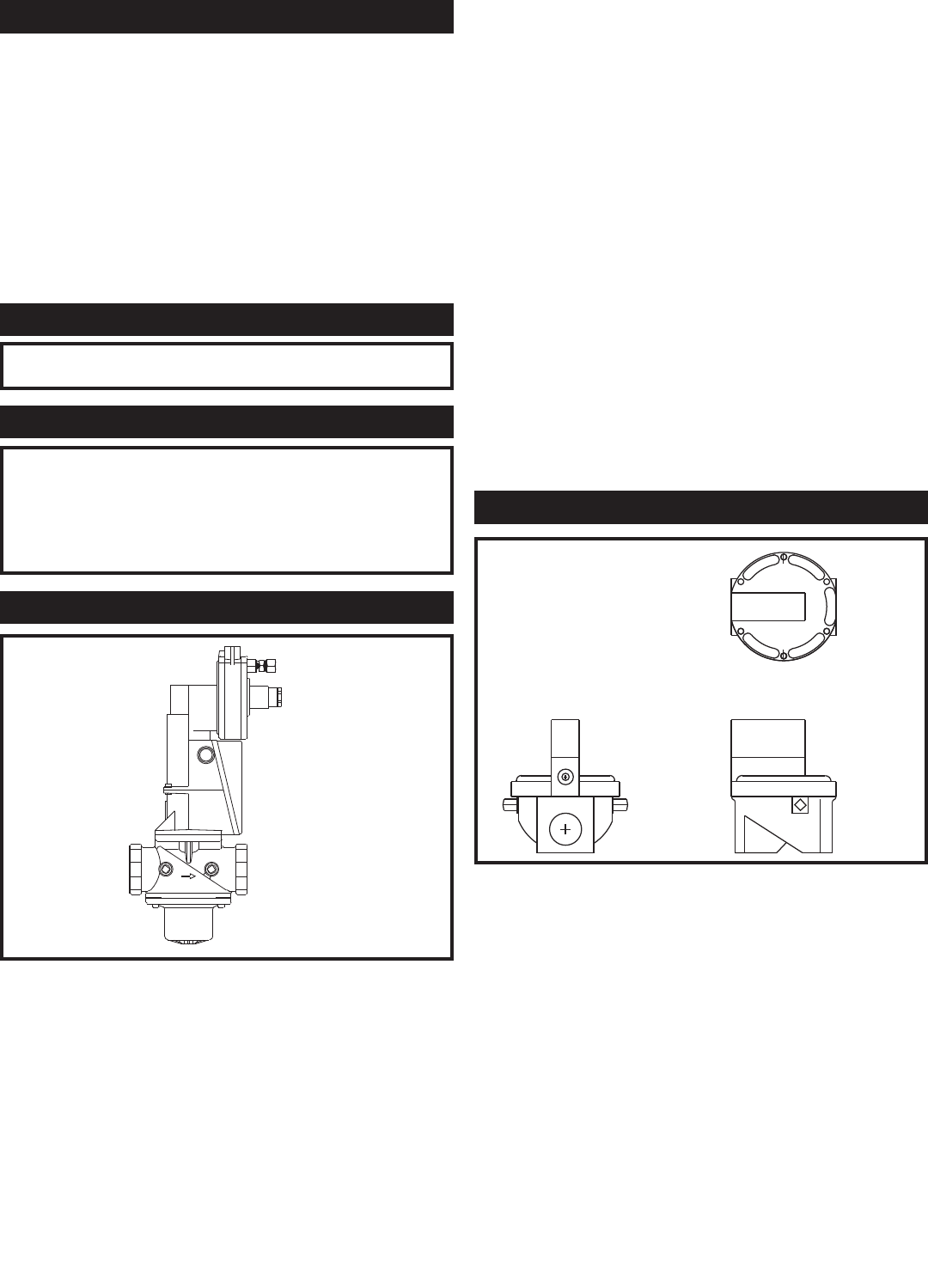

RATIO GAS VALVE

FIG. 43 Ratio Gas Valve

The main gas valve supplying gas to the burner on this appliance

utilizes a pressure regulating electro hydraulic actuator providing a

slow opening, fast closing safety shut off and air/gas ratio control

for the gas combustion process. This gas valve controls the

pressure difference across the re stric tion in the gas supply line as a

func tion of the pressure difference across the combustion air supply

to the burn er. The actuator maintains a con stant air to gas ratio as

the volume of air changes based on the operation of the combustion

air blower. The valve is a 1:1 differential pressure air/gas ratio

controller. The valve adjusts the same pressure difference on the

gas side as it senses on the air side. The valve performs the

functions of safety shutoff, constant pressure regulation and air/gas

ratio control. Slow open ing and safety shutoff is accomplished by

operation of an electro hydraulic cylinder. Full closing of the valve

seat occurs in less than 0.8 seconds when the valve is de-energized.

A visual stroke position indicator is provided on the valve assembly

to in di cate the position of the valve seat. Operation of the gas valve

in com bi na tion with the combustion air blower allows the burner

input rate to vary from 25% to 100% based on temperature demand.

There is no need for an ad di tion al upstream constant gas pressure

regulator internally to the appliance as long as the gas supply is

maintained within the specified minimum and max i mum pressures.

The manifold pressure is preset at the factory and adjustment is not

usually required if gas supply pressure is maintained within the

specified range. If the manifold pressure is to be mea sured, follow

the “Gas Manifold Pres sure Measurement Procedure” for proper

measurement.

There are no serviceable parts on the ratio gas valve actuator.

DIAPHRAGM GAS VALVE

FIG. 44 Diaphragm Gas Valve

A diaphragm type gas valve is also provided in the gas train. As the

second valve seat in the gas train, it supplies a redundant safety

shutoff valve seat in the gas supply to the burner to ensure safe

operation in the remote event of a gas valve failure. The diaphragm

gas valve is energized with 24 VAC power at the same time the

ratio gas valve is powered in the op er a tion al sequence to ignite the

burn er.