88

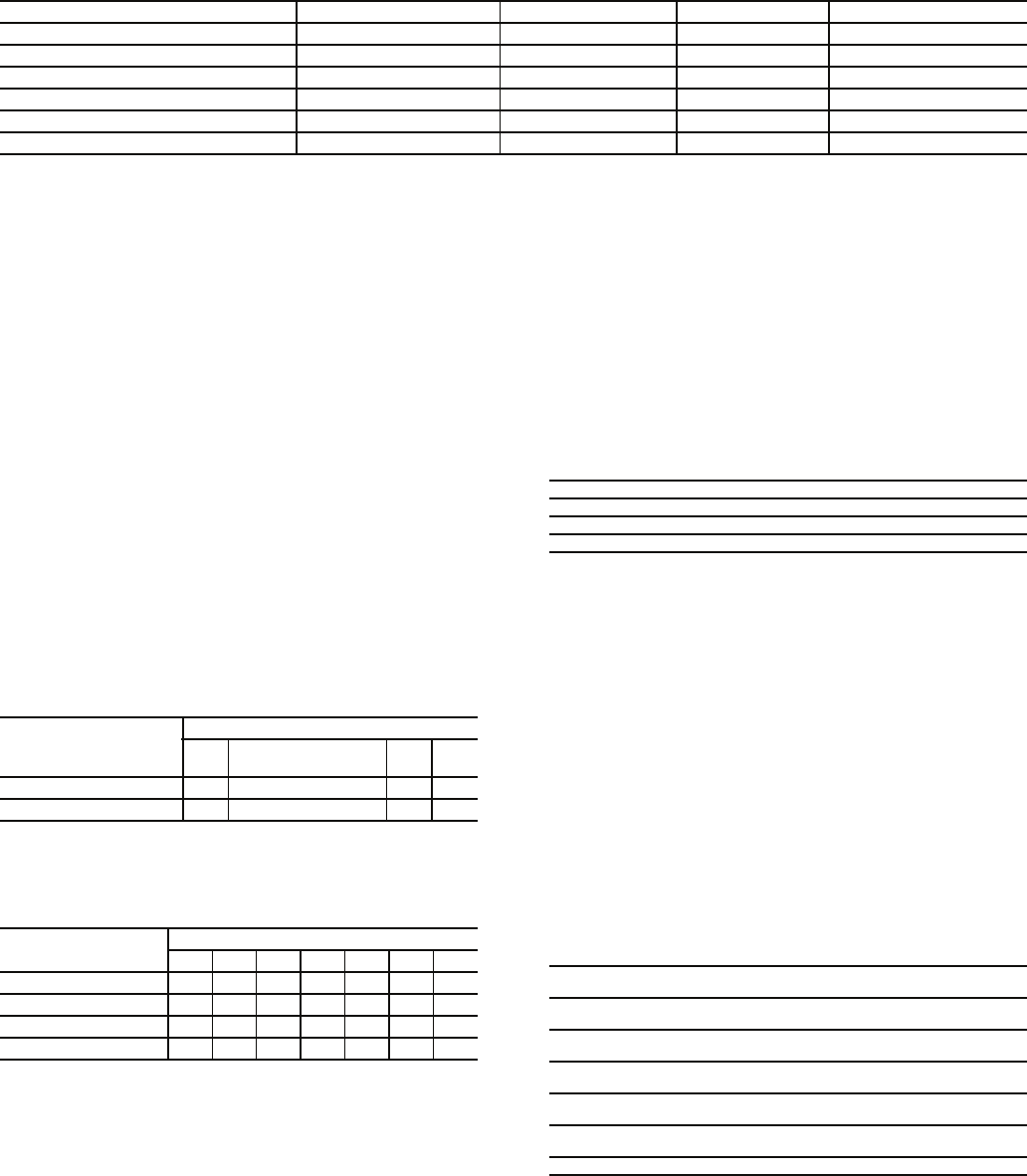

Table 41 — Smoke Control Modes

LEGEND

HEAD PRESSURE CONTROL — Each unit has a fan cy-

cling, outdoor thermostat to shut off the outdoor-fan motor(s) at

55 F (one outdoor-fan motor on 48AJ,AK,AW,AY020-030 and

48EJ,EK,EW,EY024-034 units, 2 outdoor-fan motors on

48AJ,AK,AW,AY035-050 and 48EJ,EK,EW,EY038-048 units

and 3 outdoor-fan motors on 48AJ,AK,AW,AY060 and

48EJ,EK,EW,EY054-068 units). The head pressure control

permits unit to operate with correct condensing temperatures

down to 35 F outdoor-air temperature.

MOTORMASTER® III CONTROL — The Motormaster III

Solid-State Head Pressure Control is a field-installed accessory

fan speed control device actuated by a temperature sensor. It

is specifically designed for use on Carrier equipment and con-

trols the condenser-fan motor speed in response to the saturated

condensing temperature. For outdoor temperatures down to

–20 F, it maintains condensing temperature at 100 F. Refer to

the accessory Motormaster installation instructions for more

information.

CAPACITY CONTROL, COOLING — The cooling capaci-

ty staging tables are shown in Tables 42 and 43.

Table 42 — Cooling Capacity Staging Table, CV

Units with 2 Compressors

NOTE: On CV units that require additional unloading, add suction

pressure unloaders to Compressor 1 only.

Table 43 — Cooling Capacity Staging Table VAV

Units with 2 Compressors and 2 Unloaders*

*40 ton units have only one unloader.

It is often desirable to use a variable air volume (VAV) unit

in a variable volume and temperature (VVT) control system

because of the greater unloading capability. A VAV unit (with

software version 4.0 and later) can easily be configured in the

field to run off of either space thermostat (VVT® relay pack)

input or a space sensor. When configured in this manner, the

unit control will turn on compressors based upon load in the

space. If the supply-air falls below predefined limits, the con-

trol will unload the compressor in order to maintain the mini-

mum supply-air limit. If unloading is not successful in main-

taining the minimum supply-air temperature (SAT), then the

compressors will be turned off. An alarm will be issued when

the compressors are turned off.

A VAV unit configured to run off thermostat input or a

space sensor will have the capability for two stages of heating,

however, modification to the control wiring will be required to

make this available. The Variable Frequency Drive (VFD) for

the supply fan will still be active, varying the supply air fan

speed to maintain supply duct pressure.

Upon a call for Y1 (or Y2_SPT) cooling, the compressor 1

will start after appropriate Time Guard® functions. Thirty sec-

onds after the SAT drops below the “SAT1TRIP” the compres-

sor will be unloaded. The unloading sequence will be as

follows:

The “Y1 Low SAT Limit” has an adjustable range from

50 F to 65 F, with a factory setting of 53 F. If the temperature of

the SAT rise above the “Y1 Low SAT Limit” plus 2° F, the

compressor will be loaded in the reverse order in which it was

unloaded following the pre-described time guards. There will

be a 90-second time guard between any change in unloaded

state, and the normal 5-minute time guard for change in com-

pressor On/Off state.

If compressor no. 1 is forced off due to “Y1 LOW SAT

Limit” an alert will be issued. If economizer is suitable, the

economizer mode will remain active. The alert will be cleared

after the 5-minute time guard has expired and the compressor is

restarted. With Y1 (or Y1_SPT) input, only compressor no. 1

can be running.

Upon a call for Y1 (or Y1_SPT) and Y2 (or Y2_SPT) cool-

ing both compressor no. 1 and 2 will start after appropriate time

guards. Thirty seconds after SAT drops below the “Y2 Low

SAT Limit” the compressor will be unloaded. The unloading

sequence will be as follows:

The “Y2 Low SAT Limit” has an adjustable range from

45 F to 55 F, with a factory default setting of 48 F. If the tem-

perature of the SAT rise above the “Y2 Low SAT Limit” plus

2° F, the compressor will be loaded in the reverse order in

which it was unloaded following the pre-described Time Guard

functions. There will be a 90-second time guard between any

change in unloaded state, and the normal 5-minute time guard

for change in compressor On/Off state.

DEVICE PRESSURIZATION SMOKE PURGE EVACUATION FIRE SHUTDOWN

Economizer 100% 100% 100% 0%

Indoor Fan/VFD ON ON OFF OFF

Power Exhaust (all outputs) OFF ON ON OFF

Heat Stages OFF OFF OFF OFF

Cool Stages OFF OFF OFF OFF

HIR ON ON OFF OFF

HIR — Heat Interlock Relay

VFD — Variable Frequency Drive

Stages

0

1

Economizer

23

Compressor 1 off off on on

Compressor 2 off off off on

STAGES

0123456

Compressor 1 offonononononon

Unloader 1 off on on off on on off

Unloader 2 offonoffoffonoffoff

Compressor 2 off off off off on on on

Compressor no. 1 On, Full Load Unloader no. 1 and no. 2 Off

Compressor no. 1 On,

2

/

3

Load Unloader no. 1 Off, Unloader no. 2 On

Compressor no. 1 On,

1

/

3

Load Unloader no. 1 and no. 2 On

Compressor no. 1 Off Unloader no. 1 and no. 2 Off

Compressor no. 1

On, Full Load

Unloader no. 1 and no. 2 Off Compressor no. 2 On

Compressor no. 1

On,

2

/

3

Load

Unloader no. 1 Off,

Unloader no. 2 On

Compressor no. 2 On

Compressor no. 1

On,

1

/

3

Load

Unloader no. 1 and no. 2 On Compressor no. 2 On

Compressor no. 1

On, Full Load

Unloader no. 1 and no. 2 Off Compressor no. 2 Off

Compressor no. 1

On,

2

/

3

Load

Unloader no. 1 Off,

Unloader no. 2 On

Compressor no. 2 Off

Compressor no. 1

On,

1

/

3

Load

Unloader no. 1 and no. 2 On Compressor no. 2 Off

Compressor no. 1 Off Unloader no. 1 and no. 2 Off Compressor no. 2 Off