STP-H600/H1000 Series Instruction Manual

3.3.3 How to Secure the STP Pump

The STP pump is provided with a high-speed rotor. The worst-case failure may

result in a jump in rotational torque leading to personal injury or peripheral

equipment damage.

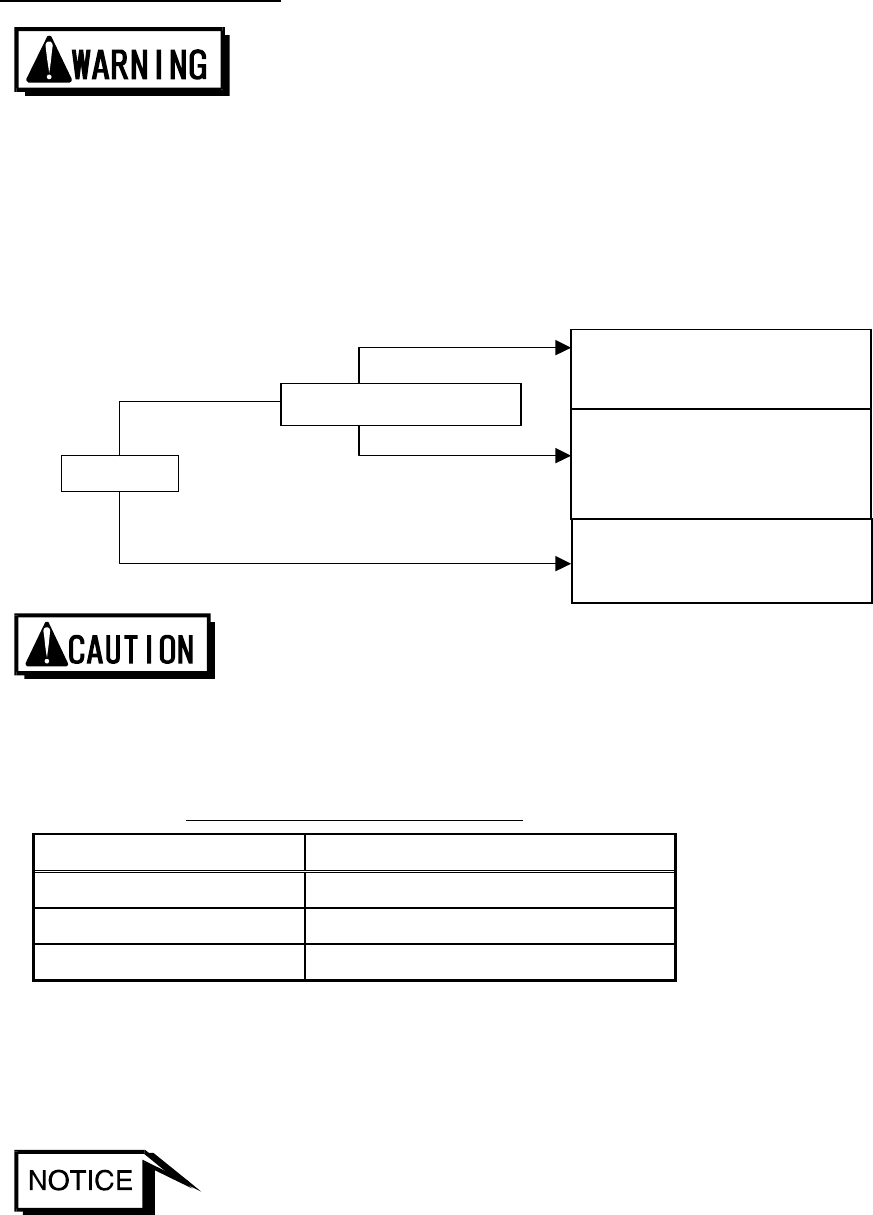

The method of securing the STP pump will depend on the installation

requirements. Secure the STP pump to the vacuum equipment as follows:

Design and secure the mounting for the STP pump so that it can withstand the

maximum rotational torque. Refer to

Table 3.2 for torque in pump abnormality.

Refer to “3) When installing the

damper in the inlet port flange”

Refer to “2) When securing the

inlet port flange with claw

clamps”

Refer to “1) When securing the

inlet port with bolts”

Secure the inlet port

with Claw Clamps

with bolts

No

Y

es

Damper

In some cases, the damper and the claw clamper securing cannot be used

depend on the type of the STP pump.

Refer to Table 3.1 for tightening torque of the bolt.

Table 3.1 Tightening torque of bolt

Size of bolt Tightening torque of bolt (Nm)

M8 12.0

M10 24.1

M12 42.1

When making the leg to secure the base, make them shortened more than ones

attached to the STP pump.

Use a material that has a tensile strength of 600N/mm

2

or more.

When securing the base, use stainless steel securing bolts with a tensile

strength class is 70 or more.

When using any securing method other than that specified in this manual,

contact Seiko Instruments.

3-8