STP-H600/H1000 Series Instruction Manual

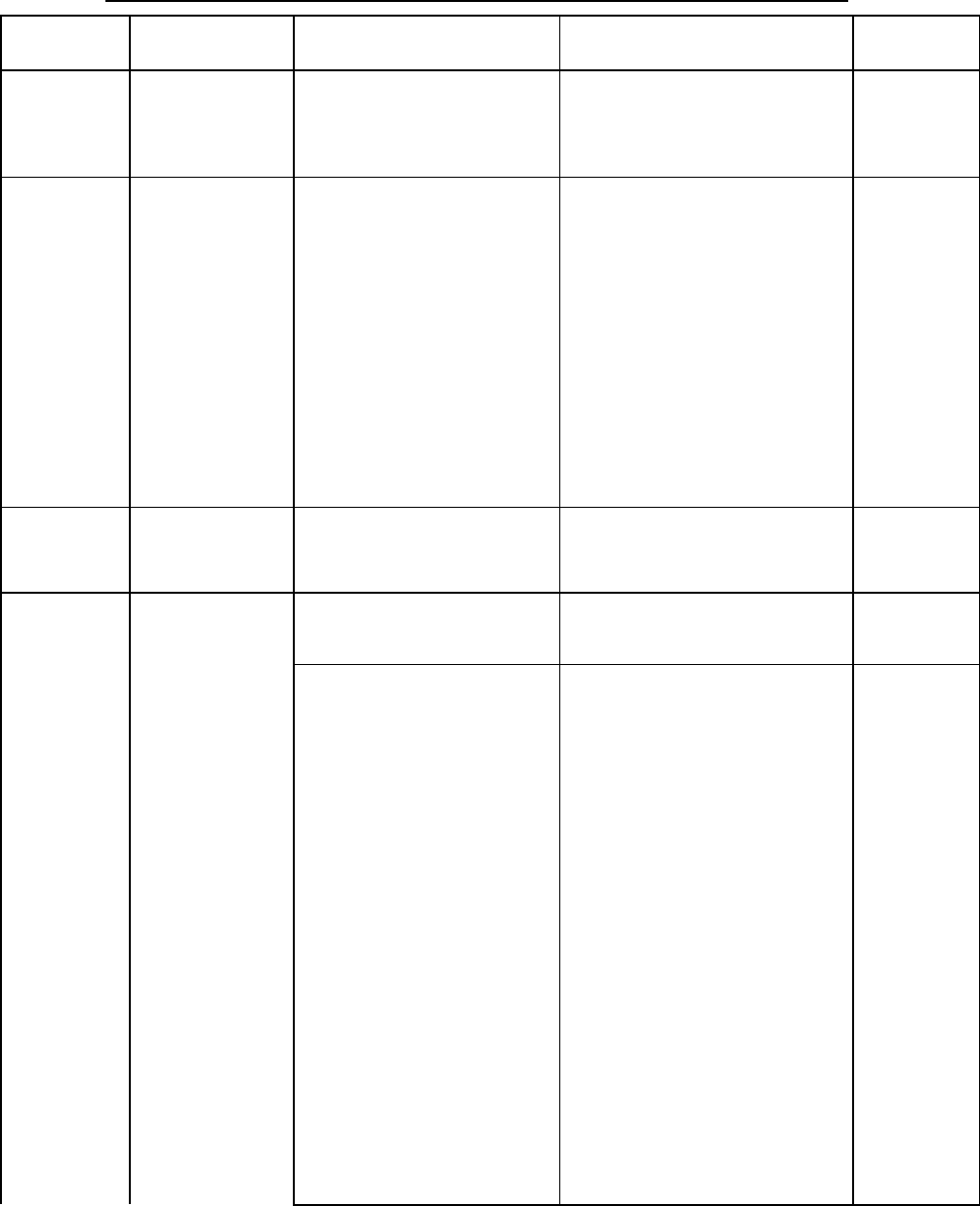

Table 15.5 Troubleshooting When Any of Abnormality/Error Warning Lamp Lights

PROCEDU

RE No.

Lamp Being Lit Probable Causes Countermeasures

Referred

Section

No.1

“OVER

TEMPERATURE”

“FAILURE”

“EMERGENCY

OPERATION”

(1) Incorrect connection of

the STP connection

cable.

Connect cables correctly.

If the cable connector is not

locked, lock it securely.

4.4.2

No.2

“OVER

TEMPERATURE”

“FAILURE”

(1) Overheat inside the STP

pump:

1) Overheat during

baking.

2) Insufficient cooling.

3) Leakage of the

vacuum piping

system.

4) Repetitious start/stop

operations.

1) Set the temperature of the

baking heater to 120 °C or

lower.

2) At the time of baking or gas

suction, always cool the STP

pump.

3) Check the piping system for

leakage.

4) Repetitious start/stop

operations may cause the

STP pump to overheat.

7.3

7.2

3.3.4

5.2

No.3

“BATTERY

OPERATION”

“EMERGENCY

OPERATION”

(1) Power failure. Check a power failure. 6.1.1

No.4

“FAILURE”

(1) Incorrect connection of

the emergency vent.

valve cable.

Connect the cable correctly. If

the cable connector is not

locked, lock it securely.

4.4.2

(2) When the rated operation

does not start approx. 15

minutes after start

operation is executed:

When the

ACCELERATION state

continues for approx. 15

minutes:

1) Insufficient pressure at

the inlet port.

2) Insufficient pressure at

the outlet port.

3) Leakage of the piping

system.

4) Failure of the auxiliary

pump.

5) Incorrect connection of

the motor connection

cable.

1) Use the maximum working

pressure or less.

2) Use the allowable backing

pressure or less.

3) Check the piping system for

leakage.

4) Check the auxiliary pump

for its capacity and START

state.

(use a pump with the

recommended capacity or

more).

5) Connect the cable correctly.

If the cable is not locked,

lock it securely.

6.1.4

3.3.4

16.1

3.3.4

16.1

3.3.4

3.3

16.1

4.4.2

15-6