STP-H600/H1000 Series Instruction Manual

PROCEDU

RE No.

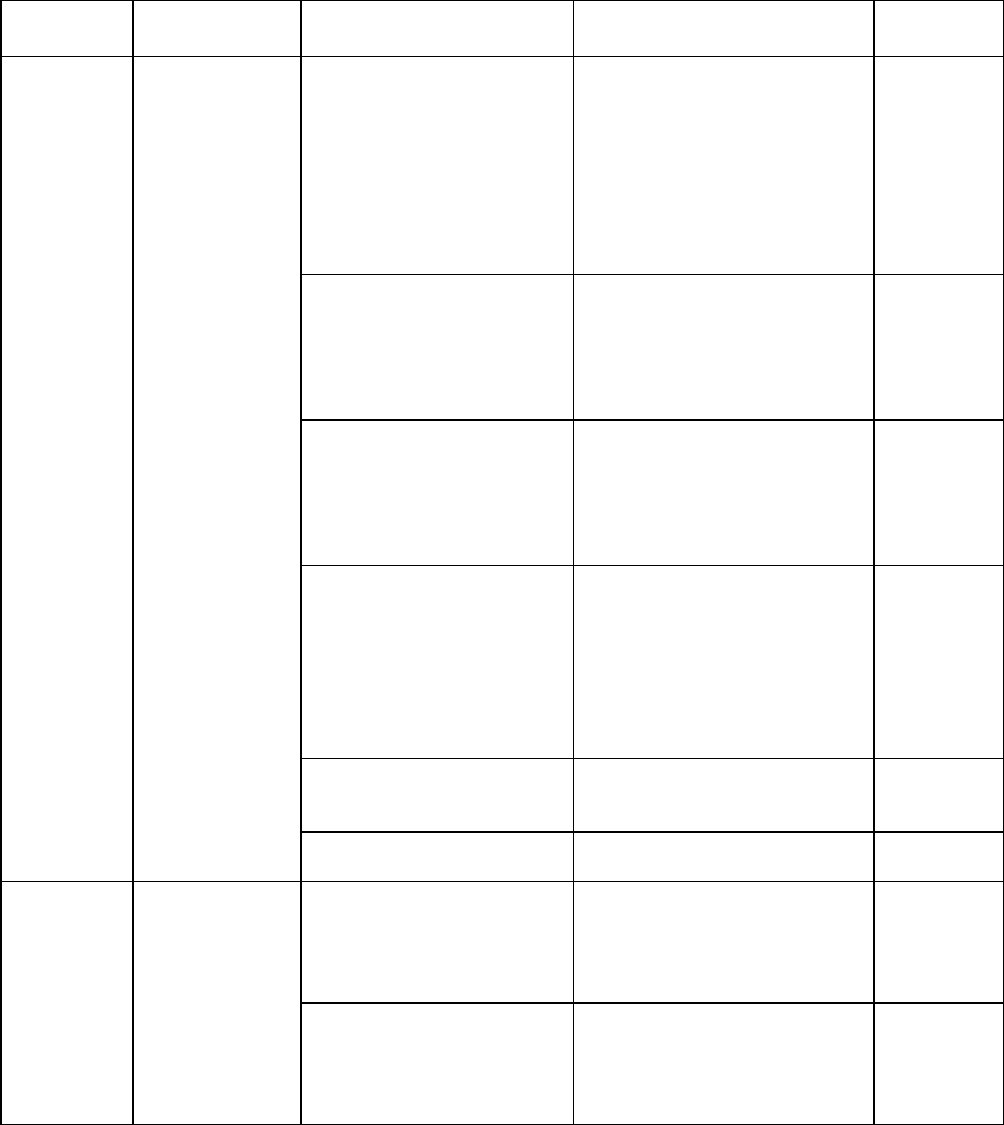

Lamp Being Lit Probable Causes Countermeasures

Referred

Section

No.4

“FAILURE”

(3) Overheating inside the

STP control unit:

1) Ambient temperature.

2) Insufficient cooling of

the STP control unit.

1) Set the ambient

temperature to 40 °C or

lower.

2) Remove obstacle from the

ventilation port.

If the air cooling fan is

broken, contact Seiko Seiki.

4.2.1

4.2.2

12.2

(4) Peripheral equipment

abnormality (when

peripheral equipment is

connected between TB3

R.P. THER (1)–(3)).

Remove abnormalities from

peripheral equipment.

8.2

(5) TB3 R. P. THER (1)–(3)

are opened.

(when peripheral

equipment is not

connected between TB3

R. P. THER (1)–(3).

Short the circuit between

terminals (1)–(3).

8.2

(6) Insufficient charging or

deterioration of the

battery.

Check that the battery is fully

charged. If the battery is not

charged, charge it. Check the

battery for deterioration and

the next replacement date.

If the battery deteriorates or

its replacement date has

passed, replace it.

9

10

(7) Incorrect connection of

the battery.

Check that external or internal

batteries are correctly

connected.

9

10

(8) Blown fuses F8, F9 (for

battery protection).

Replace the blown fuses

(250 V, 10 A).

12.3

No.5

“EMERGENCY

OPERATION”

(1) Different model name or

No. on the name plate.

Check that the model name,

serial number and cable length

of the STP pump, the STP

control unit and the STP

connection cable are the same.

Safety

Precautions

4.4.2

(2) Excessive external

vibration (vibration of

100 mm p-p or more).

After the STP pump stops

thoroughly, power OFF and

remove external vibration so

as not to transmit it to the STP

pump.

6.1.3

15-7