88

TROUBLESHOOTING

AND MAINTENANCE

Lubrication

Keep the specified lubrication intervals.

If the machine is not lubricated as specified, thread breakage could take place.

Use only Toyota genuine SF oil or equivalent (#150 spindle oil: ISO viscosity grade = VG18).

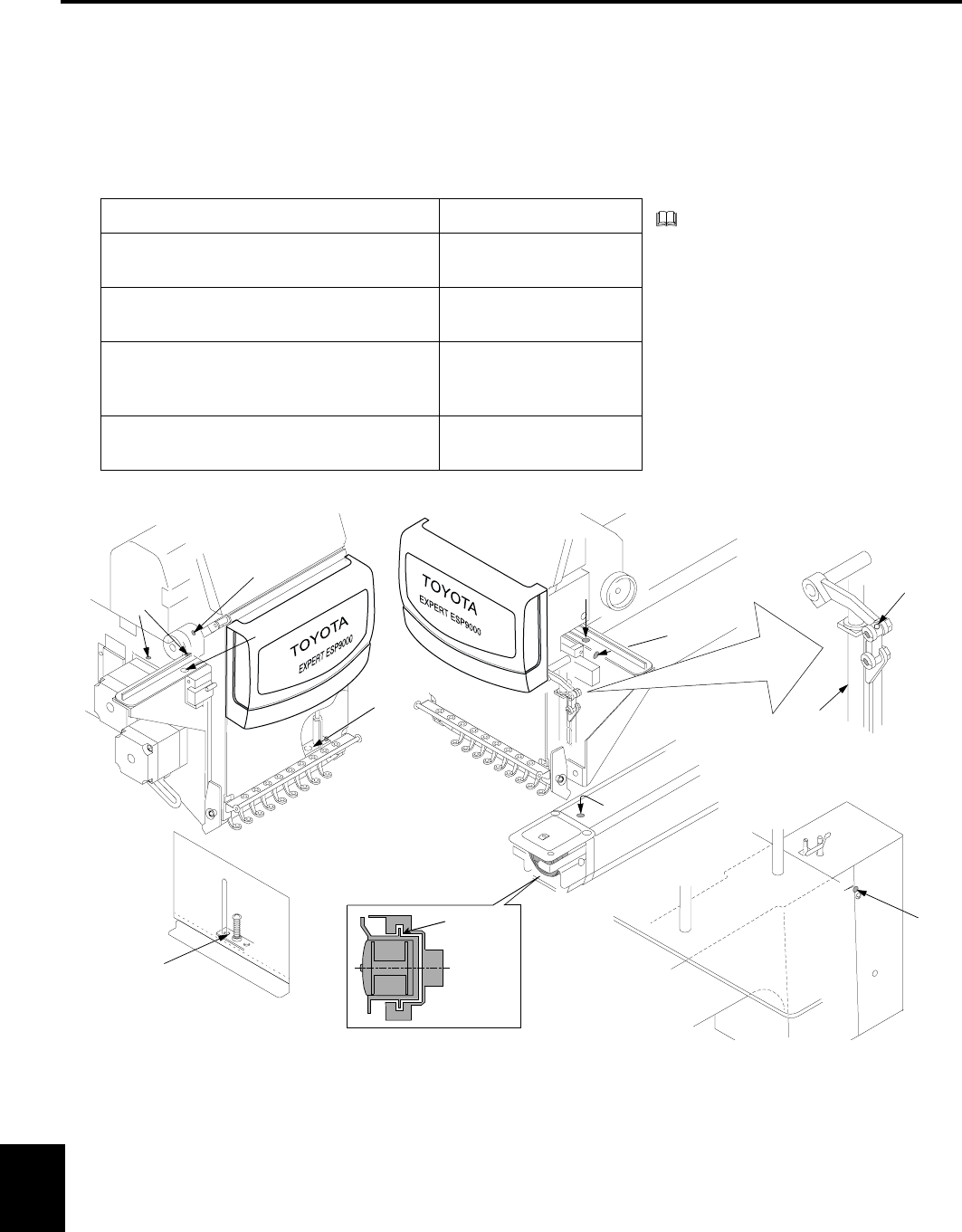

Lubrication Points Interval

1 Rail on rotary hook Every 3 to 4 hours of

operation

2 Drive shaft of presser foot parts (2 places)

3 Needle bar drive shaft (2 places)

Every day

4 Needle bar drive shaft of presser foot

5 Inside the arm (3 places)

6 Needle bar

Once/week

7 Inside the cylinder bed

8 Felt packing (needle bar)

Once/3 months

FD07

For the lubrication of rotary hook rails,

the maintenance information is dis-

played on the LCD screen in the opera-

tion panel (Page 86).

If the maintenance information is dis-

played, turn the power switch OFF and

supply lubricating oil to the rotary hook

rails.

For other lubrication cycles, refer to the

table in the left.

8

5

3

3

5

7

5

2

1

Sectional

View

6

3

4