Appendix C VCR and Swagelok Fittings 89

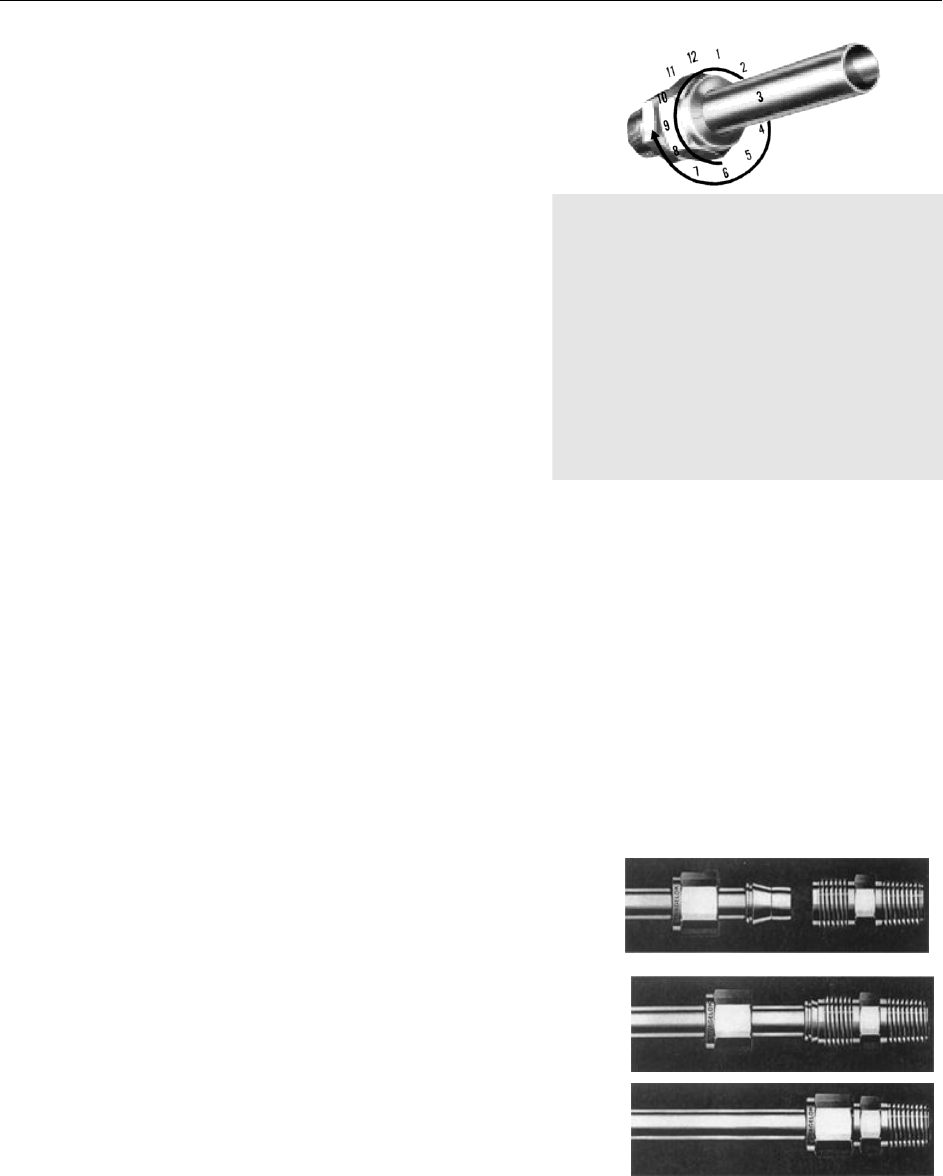

3. Hold the fitting body steady with a

backup wrench and tighten this nut 1¼

turns. Watch the scribe mark, making

one complete revolution and continue to

the 9 o’clock position.

By scribing the nut at the 6 o’clock position

as it appears to you, there will be no doubt

as to the starting position. When the nut is

tightened 1¼ turns to the 9 o’clock position,

you can easily see that the fitting has been

properly tightened.

Use of the Gap Inspection Gauge (1¼ turns

from finger-tight) ensures sufficient pull-up.

Notes:

1. For 1/16, 1/8, 3/16, 2 mm, 3 mm and

4 mm size tube fittings, only ¾ turn

from finger tight is necessary.

2. A Swagelok Hydraulic Swaging unit

must be used for assembly of Swagelok

Tube Fittings onto 1¼, 1½, 2, 28

mm, 32 mm, and 38 mm outside

diameter steel and stainless steel

tubing.

High Pressure Applications

or High-Safety-Factor Systems

Due to variations in tubing diameters, a common starting point is desirable. Using a

wrench, tighten the nut to the SNUG position. Snug is determined by tightening the nut

until the tubing will not rotate freely (by hand) in the fitting. If tube rotation is not

possible, tighten the nut approximately 1/8 turn from the finger-tight position. At this

point, scribe the nut at the 6 o’clock position and tighten the nut 1¼ turns. The fitting

will now hold pressures well above the rated working pressure of the tubing.

Retightening Instruction

Connections can be disconnected and retightened many times. The same reliable leak-

proof seal can be obtained every time the connection is remade. Directions follow.

1. Fitting shown in the disconnected position

2. Insert tubing with preswaged ferrules into

fitting body until front ferrule seats.

3. Tighten nut by hand. Rotate nut to the original

position with a wrench. An increase in

resistance will be encountered at the original

position.

Then tighten slightly with the wrench. Smaller tube sizes will take less tightening to

reach the original position, while larger tube sizes will require more tightening. The wall

thickness will also have an effect on tightening.