3 - 9

3 COMMON PARAMETERS

3.1.3 Individual parameters

(1) Basic system settings

The following explains each item to be set in Basic System Settings.

(a) Operation cycle setting

1) Set the of motion operation cycle (cycles at which a position command is

computed and sent to the servo amplifier).

The setting range is 0.4ms/0.8ms/1.7ms/3.5ms/7.1ms/14.2ms/Automatic

setting. The actual operation cycle corresponding to 0.4ms is 0.444...ms.

Similarly, 0.8ms corresponds to 0.888…ms, 1.7ms to 1.777...ms, 3.5ms

to 3.555...ms, 7.1ms to 7.111...ms, and 14.2ms to 14.222…ms,

respectively.

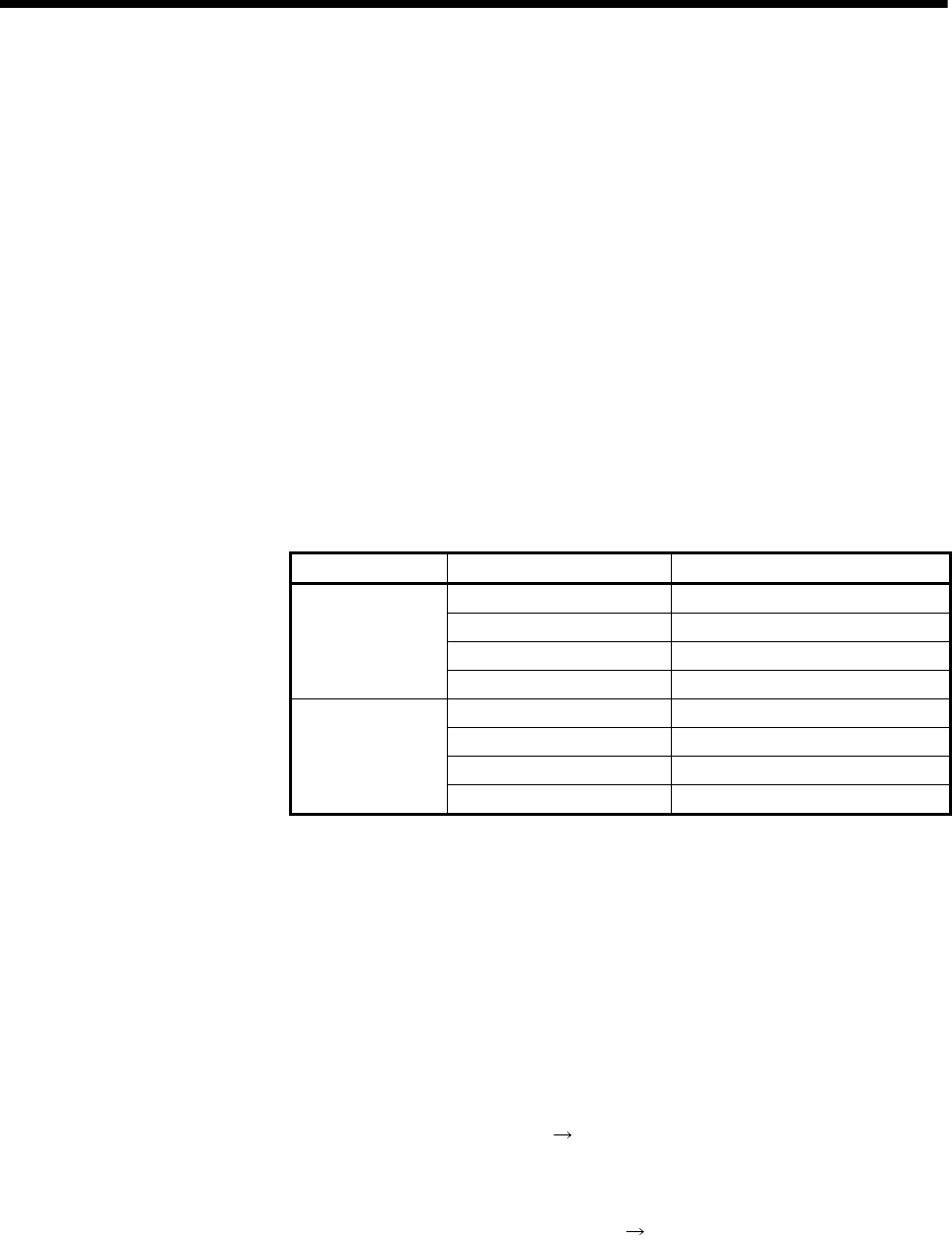

2) The default value is "Automatic setting". When "Automatic setting" is

selected, the operation cycle is set according to the table below based

on the number of axes for servo amplifier set in the System Settings.

Operating system Number of axes Operation cycle setting

1 to 3 axes 0.4 ms

4 to 10 axes 0.8 ms

11 to 20 axes 1.7 ms

SV13

21 to 32 axes 3.5 ms

1 to 5 axes 0.8 ms

6 to 14 axes 1.7 ms

15 to 28 axes 3.5 ms

SV22/SV43

29 to 32 axes 7.1 ms

3) If the duration of motion operation has exceeded the operation cycle, the

operation cycle over flag (M2054) turns ON. Even when "Automatic

setting" is selected, the duration of motion operation may exceed the

operation cycle depending on the control conditions. The actual duration

of motion operation (unit:μs) is stored in the D9188, and the current

setting of operation cycle (unit:μs) is stored in the D9197. Monitor these

special registers and adjust the set value of operation cycle so that the

actual duration of motion operation will not exceed the set operation

cycle. (A WDT or other error may occur in the Motion CPU.)

(b) Operation setting upon STOP

RUN

Set the condition in which the "PLC ready" flag (M2000) turns ON. Select

one of the following:

1) M2000 ON upon switching (STOP

RUN) (default)

Condition in which the M2000 turns from OFF to ON

• Change the RUN/STOP switch from the STOP side to the RUN side.

• With the RUN/STOP switch set to the RUN side, turn ON the power

or cancel the reset.