AIR QUALITY SENSOR — Air quality (AQ) sensors are

CO

2

sensors shipped inside the fan section for field instal-

lation. To wire the sensors after they are mounted in the con-

ditioned air space and return air duct, see Fig. 62 and the

instructions shipped with the sensors. For each sensor, use

two 2-conductor 20 AWG twisted-pair cables (unshielded)

to connect the separate 24 vac power source to the sensor

and the sensor to the option module (PSIO slave) terminals.

To connect each AQ sensor to the option module, identify

the positive (ϩ) and negative (−) terminals on the sensor;

connect AQ1 to terminals 25 and 26 and connect AQ2 to

terminals 28 and 29.

OUTSIDE AIR VELOCITY PRESSURE (OAVP) SEN-

SOR — The OAVP sensor is factory installed and wired. As

shown in Fig. 62, the sensor’s power wiring is connected to

TB2, 9 and 10 for 39L units or TB2, 29 and 30 for 39NX

units; the signal leads are connected to terminals 31 and 32

in the option module.

FAN VOLUME CONTROL (Fig. 63)

Airflow Monitoring Stations are field-selected and field-

installed in the supply and return air ducts; see Fig. 63.

Install each monitoring station in a straight portion of the

duct with any upstream or downstream elbows or fittings at

least 2.5 diameters away.

Use approved plenum tubing to connect each monitoring

station to the bulkhead fittings on top of the control box. For

runs up to 50 ft, use

1

⁄

4

-in. OD tubing. For runs over 50 ft,

use

3

⁄

8

-in. OD tubing.

Differential Pressure Transducers for fan volume control are

factory-installed in the control box (two are supplied). The

power supply for the transducers is also factory installed.

Both transducers have pressure ranges of 0.0 to 1.0 in. wg

and produce 2 to 10 vdc signals. See Fig. 64 for wiring

details.

Note that if the velocity pressure of the supply and/or re-

turn air is below 0.75 in. wg, the system may require trans-

ducers with lower ranges than those of the default factory-

supplied transducers. As a general rule, size transducers

so that the maximum air velocity pressure is 75% of the

transducer’s maximum value. For example, if the 39L or

39NX unit produces a maximum air velocity pressure of

0.15 in. wg, a transducer with a maximum value of

0.20 in. wg can be used. Sizing the transducers according to

these guidelines ensures that they have good resolution.

Factory-Supplied Return Fans with Inlet Guide Vanes

(IGVs) are factory wired except for the air supply control

signal from the airflow monitoring stations, which is con-

nected in the field to the bulkhead fitting.

Return Fans with Field-Supplied IGV Actuators must be able

to receivea4to20mAsignal and may NOT have an im-

pedance of more than 600 ohms. An isolated power source

must be field-supplied and installed. See Table 9 for

recommended actuators.

To install actuators, see Fig. 65. Using a 2-conductor

20 AWG conductor cable (one twisted pair, unshielded) rated

for the application, connect the positive (ϩ) wire to terminal

37 in the option module. Connect the negative (−) wire to

terminal 38. Connect the 24 vac power leads to TB2,

terminals 23 and 24.

Field-Supplied Return Fans with Variable Frequency Drives

must have 4 to 20 mA signal input boards and their own

field-supplied and installed power sources.

To install return fans with variable frequency drives,

see Fig. 66. Using a 2-conductor 20 AWG conductor cable

(one twisted pair, unshielded) rated for the application, con-

nect the positive (ϩ) signal wire to terminal 37 in the

option module. Connect the negative signal (−) wire to

terminal 38.

The supply fan minimum set point must be equal to the

return fan minimum airflow, plus the delta airflow that is to

be maintained.

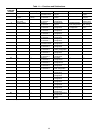

LEGEND

AQ — Air Quality Sensor

OAVP — Outside Air Velocity Pressure Sensor

Field Wiring

Factory Wiring

NOTE: See unit label diagram or Fig. 12 for remote-mount control

box connections.

Fig. 62 — Air Quality and OAVP Sensor Wiring

IGV — Inlet Guide Vane

Field Wiring

NOTE: Air monitoring stations are field supplied and installed; pres-

sure transducers are factory supplied and installed.

Fig. 63 — Field-Installed Fan Volume Control

62