YORK INTERNATIONAL60

PRINTERS

A printer can be connected to the OptiView Remote

Control Center’s Microboard to print the following

reports. The screen from which each report can be

generated is listed in parenthesis.

• Operating Data - Present system parameters

(Unit)

• History - System parameters at the time of the

last fault while running and last saved faults

(History)

The printer can be permanently connected to the Remote

Control Center or connected as required to produce a

report. If permanently connected, a DATA LOGGING

feature can produce a Status report automatically,

beginning at an Operator selected start time and occurring

at an Operator selected interval thereafter.

The following gures are examples of the different

print reports.

• Figure 28 - Operating Data

• Figure 29 - History (Header)

PRINTERS

The following Printers can be used. Printers must be

equipped with an RS-232 Serial interface.

• Okidata –

Models: 182,182 turbo, 184 turbo

Dimensions: 14 in. wide x 10.5 in. deep

Paper: 8.5 in. wide

Type: Dot matrix impact

• Weigh-Tronix –

Models: 2600, 1220

Dimensions: 2.3 in. wide x 2.8 in. deep

Paper: 2.25 in. wide

Type: Dot matrix impact

• Seiko –

Model: DPU414-30B (Power supply PW4007-U

I required)

Dimensions: 6.3 in. wide x 6.7 in. deep

Paper: 4.4 in. wide

Type: Thermal

Purchase: Contact your local

YORK Service Ofce

The OptiView Remote Control Center provides the

required formatting control codes for the printers above

when the printer is selected on the PRINTER Screen

in the instructions below. These codes are transmitted

through the serial interface to the printer to provide a

proper print format. Different printers require different

formatting control codes. Other printers might provide

proper operation when connected to the OptiView

Remote Control Center. However, the print format

may not be correct or as desired. Proceed with caution

and use the following guidelines if an unlisted printer

is selected:

1. All must be capable of RS-232 Serial communications.

2. Primary differences between printers involve the

formatting control codes required by the printer.

These codes are sent from the Control Center to

the printer. For example, Weigh-Tronix printers

require a control code to select 40 column width.

This same code is interpreted by the Okidata printer

as an instruction to print wide characters. In some

instances, a printer will ignore a code it cannot

interpret.

3. The OptiView Remote Control Center requires

a busy signal from the printer when the printer

receive buffer is full. This causes the OptiView

Remote Control Center to momentarily terminate

data transmission until the printer can accept more

data. The busy signal polarity must be asserted

low when busy.

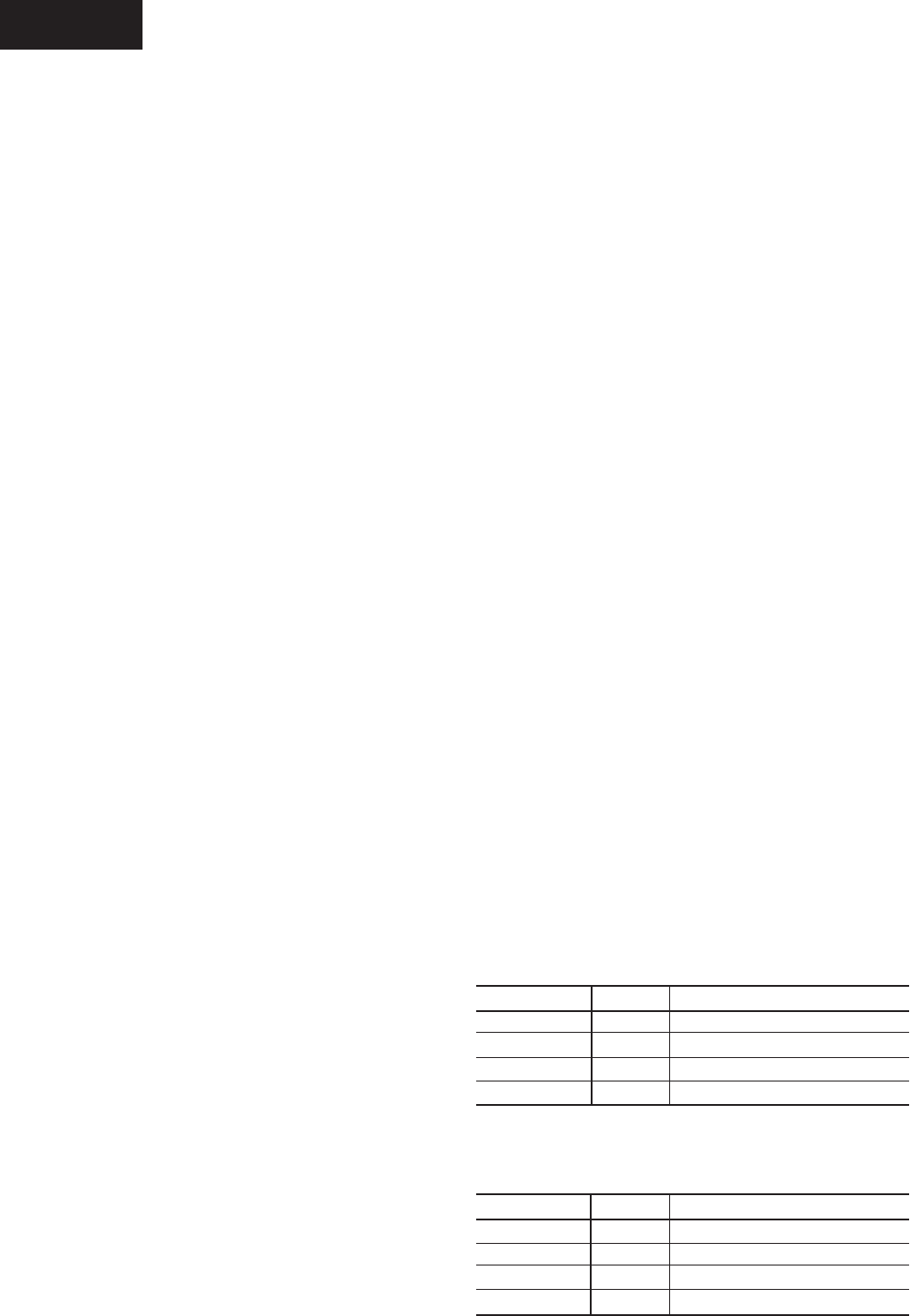

PRINTER CONNECTIONS

Connect the printers to the Control Center Microboard as

follows. Only one printer can be connected at a time.

• OKIDATA 182, 182 turbo, 184 turbo

Microboard Printer Function

J2-4 pin 3 Tx (data to printer)

J2-2 pin 11 DSR (busy signal from printer)

J2-9 pin 7 Gnd

Cabinet shield

• WEIGH-TRONIX

Microboard Printer Function

J2-4 pin 2 Tx (data to printer)

J2-2 pin 5 DSR (busy signal from printer)

J2-9 pin 7 Gnd

Cabinet shield

Printers