76

11.2.3 PLC assignment

After you determine the control items of the connected instrument, assign PLC terminals.

General-purpose control PLC needs to have one DI board and one DO board mounted regardless of the

control items. (There are certain restrictions about the mounting location and others. Refer to 12.3 for

details.)

Table 11-3 shows the general-purpose control PLC terminal assignment. Since each terminal in PLC has a

pre-determined function, keep the terminal un-connected (open) where the signal is not to be used.

11.2.4 Required materials

Members required for general-purpose control are listed in the Table 9-3.

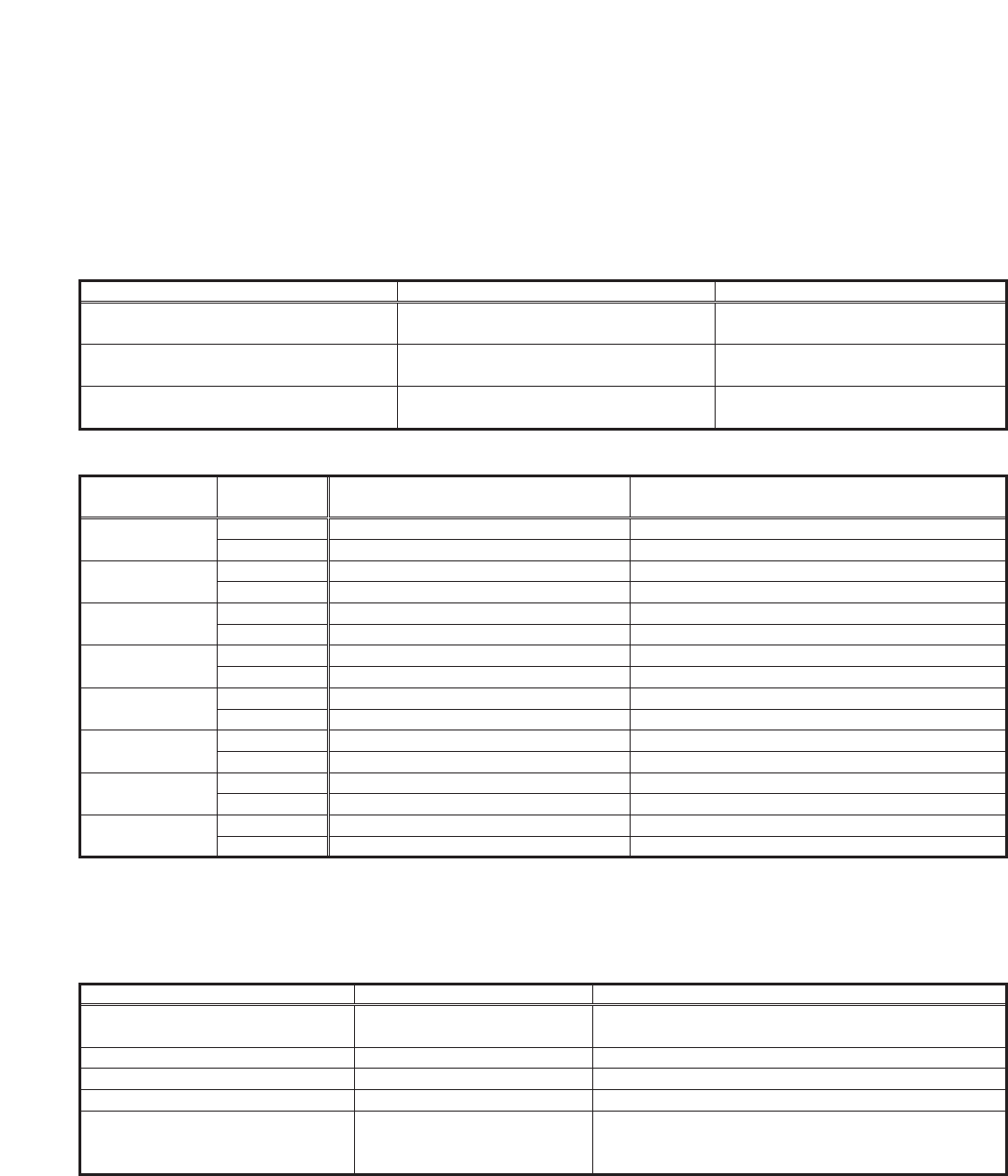

Table 11-2 General-purpose control PLC restrictions

Item

Number of general-purpose instrument that

can be connected to one PLC

Number of general-purpose control PLC that

can be connected to TG-2000A

IP address setting range for general-purpose

control PLC

Content

Up to 8 units

20 units

192.168.1.171 ~ 192.168.1.190

Remarks

8 units regardless of the control items

Number of general-purpose instrument:

160

Recommended setting range is shown.

Table 11-3 General-purpose control PLC terminal assignment

Control instrument

number

General-purpose

instrument 1

General-purpose

instrument 2

General-purpose

instrument 3

General-purpose

instrument 4

General-purpose

instrument 5

General-purpose

instrument 6

General-purpose

instrument 7

General-purpose

instrument 8

DI board

General-purpose instrument 1 ON signal

General-purpose instrument 1 OFF signal

General-purpose instrument 2 ON signal

General-purpose instrument 2 OFF signal

General-purpose instrument 3 ON signal

General-purpose instrument 3 OFF signal

General-purpose instrument 4 ON signal

General-purpose instrument 4 OFF signal

General-purpose instrument 5 ON signal

General-purpose instrument 5 OFF signal

General-purpose instrument 6 ON signal

General-purpose instrument 6 OFF signal

General-purpose instrument 7 ON signal

General-purpose instrument 7 OFF signal

General-purpose instrument 8 ON signal

General-purpose instrument 8 OFF signal

DO board

General-purpose instrument 1 operation status signal

General-purpose instrument 1 error status signal

General-purpose instrument 2 operation status signal

General-purpose instrument 2 error status signal

General-purpose instrument 3 operation status signal

General-purpose instrument 3 error status signal

General-purpose instrument 4 operation status signal

General-purpose instrument 4 error status signal

General-purpose instrument 5 operation status signal

General-purpose instrument 5 error status signal

General-purpose instrument 6 operation status signal

General-purpose instrument 6 error status signal

General-purpose instrument 7 operation status signal

General-purpose instrument 7 error status signal

General-purpose instrument 8 operation status signal

General-purpose instrument 8 error status signal

Terminal

board number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Table 11-4 General-purpose control required items

Materials (model names)

PC for centralized control

Integrated software (PAC-TG2000A)

Web monitor license

PLC

General-purpose control software

(PAC-YG21CDA)

Maker

PC/AT compatible

Mitsubishi Electric

Mitsubishi Electric

Mitsubishi Electric

Mitsubishi Electric

Remarks

Verified the performance of IBM, DELL, and Hp Compaq.

Refer to Table 6-4 for the PC specification.

Use Ver. 4.1 or later version.

Requires for each G-50A.

Make sure DI board and DO board are mounted.

This software should be installed in PLC.

The software is different depending on IP address. IP

address needs to be designated. (Standard: 192.168.1.171)