vii

12.3.3.3 Alarm No...................................................................................................414

12.3.3.4 Control Signals (PLC axis control information data)................................415

12.3.3.5 Axis Designation.......................................................................................417

12.3.3.6 Operation Mode........................................................................................417

12.3.3.7 Feedrate ...................................................................................................418

12.3.3.8 Movement Data ........................................................................................418

12.3.3.9 Machine Position ......................................................................................419

12.3.3.10 Remaining Distance ...............................................................................419

12.3.4 Reference Point Return near Point Detection ......................................................420

12.3.5 Handle Feed Axis Selection..................................................................................421

Appendix 1. Example of Faulty Circuit....................................................................................422

Appendix 2. MELSEC QnA Series Command Lists ...............................................................423

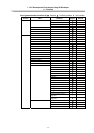

2.1 Sequence Commands .....................................................................................................423

2.2 Basic Commands.............................................................................................................424

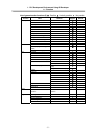

2.3 Application Commands....................................................................................................429

2.4 Exclusive Commands ......................................................................................................432

Appendix 3. PLC Development Environment using GPPQ ..................................................433

3.1 System Configuration at PLC Development....................................................................433

3.2 Development Tool Function Outline ................................................................................433

3.2.1 CNVQ (data conversion software package) ...........................................................433

3.2.2 LNKQ (sequence ladder generating connection function software package)........433

3.2.3 GPPQ (SW2IVD/NX-GPPQ type GPP Function Software Package) ....................434

3.3 GPPQ Function Outline and Functions Supported by the C64 Series ...........................435

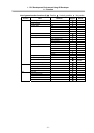

3.3.1 Function Support Conditions (general section) ......................................................435

3.3.2 Function Support Conditions (on-line section)........................................................438

3.4 Setup Procedure..............................................................................................................444

3.4.1 Tool Setup Procedure .............................................................................................444

3.4.2 Connection Procedure ............................................................................................444

3.5 PLC Program Development Procedure...........................................................................445

3.5.1 Precautions before Development ...........................................................................445

3.5.2 Ladder Transfer to the C64 Controller....................................................................446

3.5.3 Ladder Read from the C64 Controller.....................................................................448

3.5.4 Ladder Comparison with the C64 Controller ..........................................................449

3.6 PLC-Related Data Development Procedure ...................................................................450

3.6.1 PLC Related Data File Names................................................................................450

3.6.2 Development Procedure .........................................................................................451

3.6.3 Message Data Description Method.........................................................................452

3.6.4 Conversion to GPPQ Data......................................................................................457

3.6.5 Operation with the GPPQ .......................................................................................459

3.6.6 Transfer to the Controller ........................................................................................461

3.6.7 Reading and Comparing from the Controller..........................................................462

3.7 Differences From The M500 PLC Development Environment........................................464

3.7.1 PLC Commands......................................................................................................464

3.7.2 PLC Messages........................................................................................................466