- 44 -

[ II Restrictions ]

GBHWE09080

(4) Wiring method

1) Indoor-heat source transmission line

Same as [5] 7.

Only use shielded cables.

Shielded cable connection

Same as [5] 7.

2) Transmission line for centralized control

Daisy-chain terminals A and B on the system controller, ter-

minals M1 and M2 on the terminal block for transmission line

for centralized control (TB7) on the heat source units (OC)

in different refrigerant circuits and on the heat source units

(OC and OS) in the same refrigerant circuit.

If a power supply unit is not connected to the transmission

line for centralized control, replace the power jumper con-

nector on the control board from CN41 to CN40 on only one

of the heat source units.

If a system controller is connected, set the central control

switch (SW2-1) on the control board of all heat source units

to "ON."

The heat source units in the same refrigerant circuit are

automatically designated as OC, OS1, and OS2 in the

order of capacity from large to small (if two or more units

have the same capacity, in the order of address from

small to large).

Only use shielded cables.

Shielded cable connection

Daisy-chain the S terminal of the terminal block (TB7) on

the system controller, OC, and OS with the shield of the

shielded cable. Short-circuit the earth terminal ( ) and

the S terminal on the terminal block (TB7) on the heat

source unit whose power jumper connector is mated with

CN40.

3) MA remote controller wiring

Same as [5] 6.

When 2 remote controllers are connected to the sys-

tem

Same as [5] 6.

Group operation of indoor units

Same as [5] 6.

4) LOSSNAY connection

Connect terminals M1 and M2 on the terminal block

(TB5) on the indoor unit (IC) to the appropriate terminals

on the terminal block for indoor-heat source transmission

line (TB5) on LOSSNAY (LC). (Non-polarized two-wire)

Indoor units must be interlocked with the LOSSNAY unit

using the system controller. (Refer to the operation man-

ual for the system controller for the setting method.) In-

terlock setting from the remote controller is required if the

ON/OFF remote controller alone or the LM adapter alone

is connected.

5) Switch setting

Address setting is required as follows.

(5) Address setting method

The heat source units in the same refrigerant circuit are automatically designated as OC and OS.

They are designated as OC and OS in the descending order of capacity (ascending order of address if the capacities are the

same).

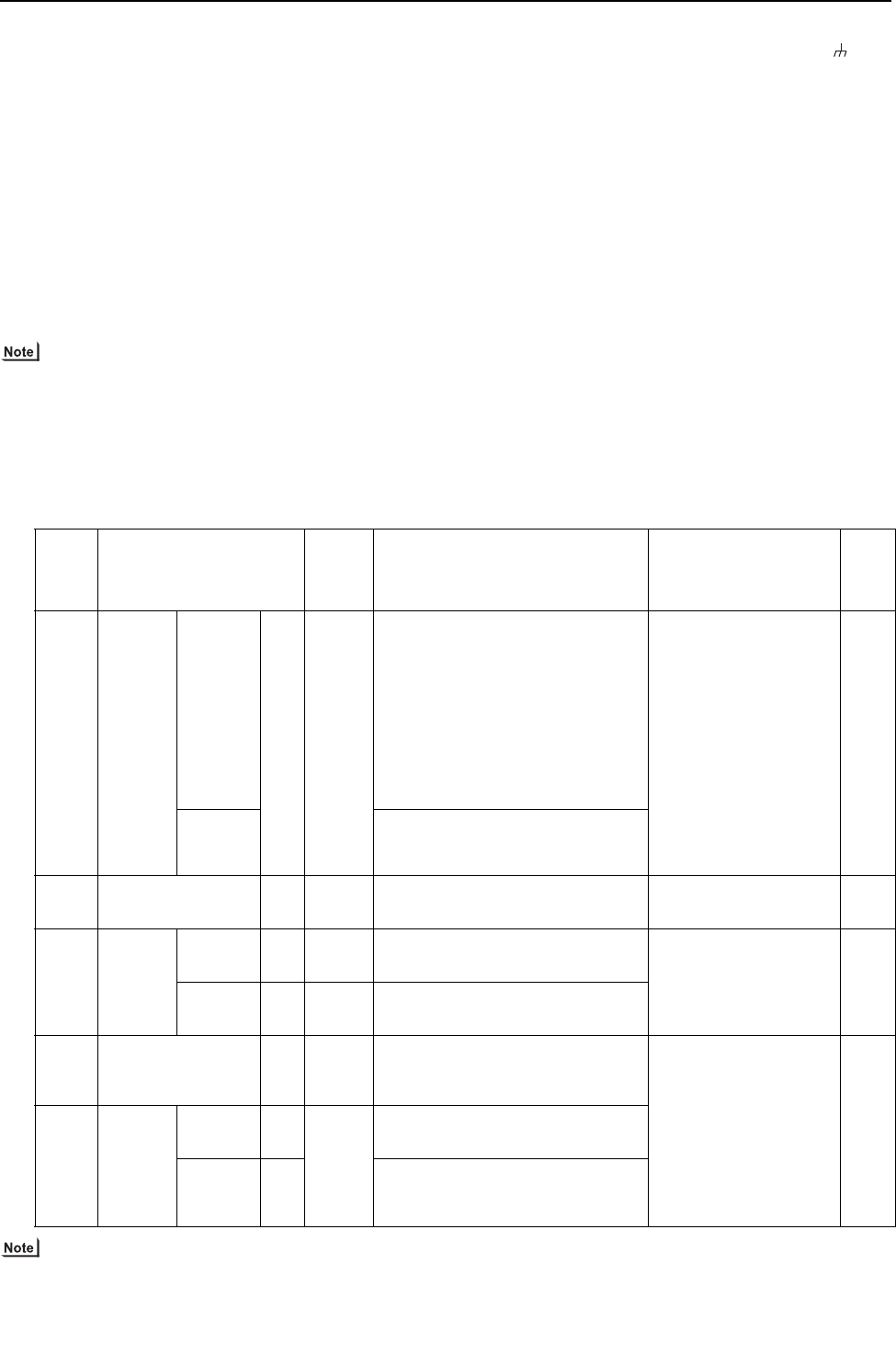

Proce-

dures

Unit or controller

Ad-

dress

setting

range

Setting method Notes

Fac-

tory

set-

ting

1 Indoor

unit

Main unit IC 01 to

50

Assign the smallest address to the main unit

in the group.

In a system with a sub BC controller, make

the settings for the indoor units in the fol-

lowing order.

(i) Indoor unit to be connected to the main BC

controller

(ii) Indoor unit to be connected to sub BC

controller 1

(iii) Indoor unit to be connected to sub BC

controller 2

Make the settings for the indoor units in the

way that the formula "(i) < (ii) < (iii)" is true.

Port number setting is

required

To perform a group op-

eration of indoor units

that feature different

functions, designate

the indoor unit in the

group with the greatest

number of functions as

the main unit.

00

Sub unit

Assign sequential numbers starting with the

address of the main unit in the same group

+1. (Main unit address +1, main unit address

+2, main unit address +3, etc.)

2 LOSSNAY LC 01 to

50

Assign an arbitrary but unique address to

each of these units after assigning an address

to all indoor units.

None of these addresses may

overlap any of the indoor unit

addresses.

00

3MA

remote

controller

Main

remote con-

troller

MA

No set-

tings re-

quired.

-

Make the same indoor unit

group settings with the system

controller as the ones that

were made with the MA remote

controller.

Main

Sub

remote con-

troller

MA

Sub

remote

controller

Settings to be made with the Sub/

Main switch

4 Heat source unit

(Note)

OC

OS

51 to 100 Assign sequential address to the heat

source units in the same refrigerant circuit.

The heat source units are automatically

designated as OC and OS.(Note)

To set the address to 100,

set the rotary switches to 50.

If the addresses that is as-

signed to the main BC con-

troller overlaps any of the

addresses that are assigned

to the heat source units or to

the sub BC controller, use a

different, unused address

within the setting range.

The use of a sub BC control-

ler requires the connection

of a main BC controller.

00

5 Auxiliary

heat

source

unit

BCcon-

troller (Sub)

BS

51 to 100 Assign an address that equals the sum of the

smallest address of the indoor units that are

connected to the sub BC controller and 50.

BC control-

ler (Main)

BC OC (or OS if it exists) +1