[ II Restrictions ]

- 22 -

HWE09080 GB

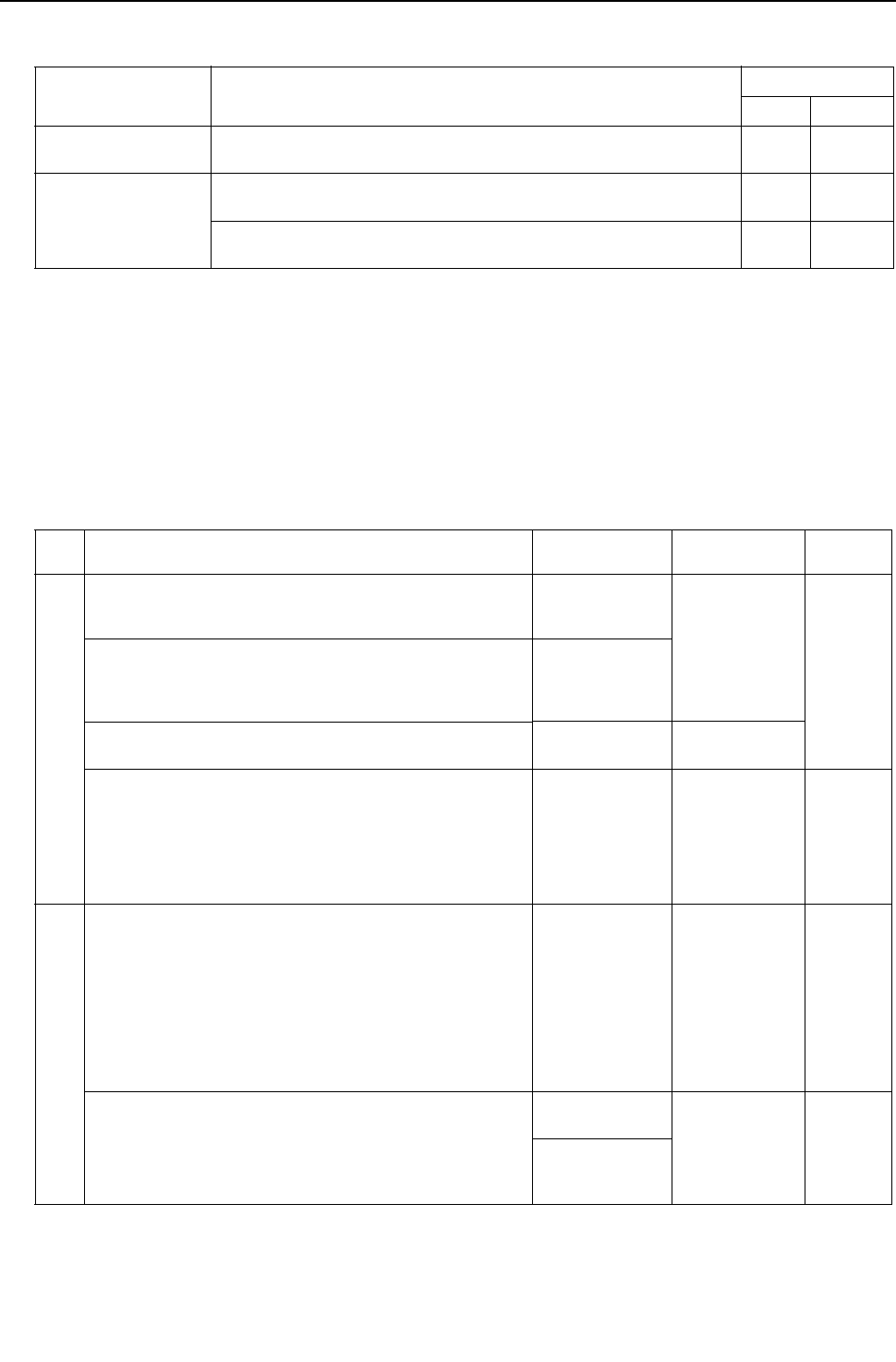

(5) Various start-stop controls (Indoor unit settings)

Each indoor unit (or group of indoor units) can be controlled individually by setting SW 1-9 and 1-10.

*1. Do not cut off power to the heat source unit. Cutting off the power supply to the heat source unit will cut off the power

supply to the crankcase heater and may cause the compressor to malfunction when the unit is put back into operation.

*2. Not applicable to units with a built-in drain pump or humidifier.

*3. Models with a built-in drain pump cannot be turned on/off by the plug individually. All the units in the same refrigerant cir-

cuits will be turned on or off by the plug.

*4. Requires that the dipswitch settings for all the units in the group be made.

*5. Set SW1-9 and SW1-10 to ON to control the external input from/output to the air conditioning units via AG-150A or G(B)-

50A using the PLC software for general equipment. With these settings made, the power start-stop function becomes dis-

abled. To use the auto recovery function after power failure while these settings are made, set SW1-5 to ON.

(6) Miscellaneous settings

Cooling-only setting for the indoor unit: Cooling only model (Factory setting: SW3-1 "OFF.")

When using indoor unit as a cooling-only unit, set SW3-1 to ON.

(7) Various types of control using input-output signal connector on the heat source unit (various connection options)

Function

Operation of the indoor unit when the operation is resumed after the unit

was stopped

Setting (SW1)

*4 *5

910

Power ON/OFF by the

plug

*1,*2,*3

Indoor unit will go into operation regardless of its operation status before

power off (power failure). (In approx. 5 minutes)

OFF ON

Automatic restoration

after power failure

Indoor unit will go into operation if it was in operation when the power was

turned off (or cut off due to power failure). (In approx. 5 minutes)

ON OFF

Indoor unit will remain stopped regardless of its operation status before

power off (power failure).

OFF ON

Type Usage Function

Terminal to be

used

*1

*1. For detailed drawing, refer to "Example of wiring connection".

Option

Input Prohibiting cooling/heating operation (thermo OFF) by an ex-

ternal input to the heat source unit.

* Usable for demand control of each refrigerant system

DEMAND (level) CN3D

*2

*2. For details, refer to the next section "Demand control".

Adapter

for exter-

nal input

(PAC-

SC36NA-

E)

Performs a low level noise operation of the heat source unit by

an external input to the heat source unit.

* It can be used as the silent operation device for each refriger-

ant system.

Low-noise mode

(level)

*3 *4

Cooling/heating operation can be changed by an external input

to the heat source unit (OC).

Auto-changeover CN3N

Receives interlock operation signal input from the water circuit

pump (field-supplied)

Pump interlock

operation signal

input

TB-8 (between

poles 3 and 4)

*Minimum guar-

anteed current at

no-voltage input

contact: 5 mA or

below

_

Out-

put

Outputs signals to perform interlocked operation of heat source

unit and water circuit pump

Signal output patterns

*When DIP SW2-7 is set to off (factory setting)

Signals are output while the compressor is in operation.

*When DIP SW2-7 is set to ON

Signals are output from the controller while receiving cool-

ing or heating signal.

Signals are output while the compressor is stopped during

Thermo-OFF.

Pump interlock

operation signal

TB-8 (between

poles 1 and 2)

*Contact rating:

200VAC 1A or

below

_

How to extract signals from the heat source unit

*It can be used as an operation status display device.

*It can be used for an interlock operation with external devic-

es.

Operation status

of the compressor

CN51 Adapter

for exter-

nal output

(PAC-

SC37SA-

E)

Error status