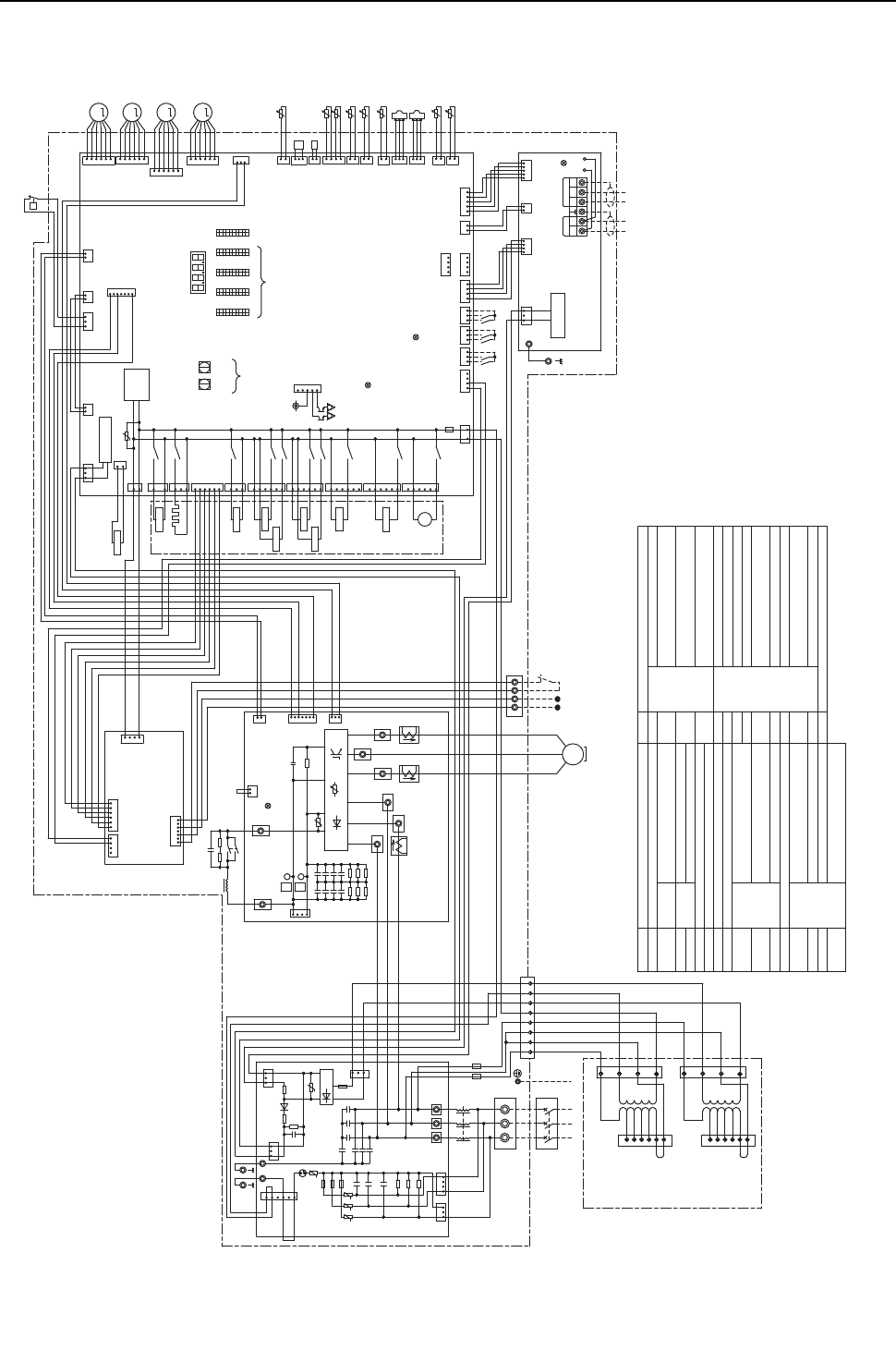

[ V Electrical Wiring Diagram ]

- 109 -

HWE09080 GB

(3) PQHY-P72, 96, 120YHMU-A

㧗

1

2

*7

Z24,25

Thermistor

Operation ON signal,

Pump Interlock

Discharge pipe temperature

ACC inlet pipe temperature

Water inlet temperature

IGBT temperature

Function setting connector

THHS

TH7

TH5

TH4

TB8

Power supply

Indoor/Heat source transmission

cable

Central control transmission

cable

Terminal

block

TB7

TB3

TB1

Subcooled liquid refrigerant

temperature

TH6

Pipe temperature

Subcool bypass outlet temperature

TH2

TH3

Outlet temp.detect of heat

exchanger for inverter

THINV

Water outlet temperatureTH8

Explanation

Symbol

L1

L2

Power Source

ޓ3~

ޓ60Hz

ޓ460V

Transformer box

purple

1

2

3

4

CN06

T02

(Transformer)

CNTR2

CN07

1

2

3

4

5

6

T03

(Transformer)

CNTR3

5

6

2

4

3

1

460V

460V

purple

1

X09

3

6

CN508

black

Unit address

setting

CN504

green

CT12

C31

C33

CN5

red

D1

R5

Z5

1

SV9

CNTR1

12

L1 L2 L2

3

L3

45678

white

TH2

t°

white

red

black

black

white

red

F4

AC 600V

3A F

C8

F5

AC 600V

3A F

red

CNIT

yellow

CNS2

t°

1

CN51

12V

Function

setting

SW1

10

1

CN212

CNTYP4

green

F4

AC250V

6.3A T

R4

F3

F1

Z4

R2

F2

*3

3

2

Compressor ON/OFF output

Error detection output

CN201

Z25

1

4

1

1

1

TH3

Z3Z2

U

ONOFF

SW2

10

1

SWU2

LED1

C4

C35

C37

R31

R33

R30

ON

SW3

10

Control Board

TH7

CN40

63HS1

CN41

TH6

t°

t°

TH4

3

2

2

2

1

SW5

LED3:Lit when powered

1

3

4

R32

2

Z1

1

DSA

C10

R34 R35

LEV1

LEV2a

C36

3

C34

SC-V

CT22

SC-U

V

1

CN4

blue

red

1

M

1

LEV2b

t

°

black

4

1

3

6

yellow

CN3K

*3

3

M

C3

TB21

C1

R3

3

M

CN1A

5

U

CN2

blue

CN3N

5

6

C7

U

44

R1

TB1

CN1B

3

TB7 Power

selecting

connector

CN102

3

2

1

2

1

U

TP1

L3

DCL

black

72C

white

red

321

ON

OFF

1

M-NET power

supply circuit

123

C6

M-NET Board

12

1

1

CNAC2

black

CN502

5

Indoor/Outdoor

transmission

cable

INV Board

red

3

CNT01

TB23

L2L1

1

ON

1

2

1's

digit

THHS

1

CNIT

red

S

2

1

1

CN990

1

W

TB3

10's

digit

OFF

LED2:CPU in operation

5

2

CNS2

yellow

TB7

1

CNDC

pink

M1

2

red

6

MS

3~

1

1

t°

C100

*5

3

3

U

1

4

LED1:Power supply to

Indoor/Outdoor

transmission line

ZNR01

M2

32

M1

black

Central control

transmission

cable

*6

SC-L1

4

C2

C9

ON

C5

OFF

FT-N

R5

Motor

(Compressor)

5

2

3

3

1

CN04

red

CN2

3

CN4

X05

2

SC-P2

P

1

CN211

CN202

red

TH5

N

CN1

M2

2

TP2

LED1:Normal operation(Lit)

/ Error(Blink)

2

CN503

blue

5

X04

4

*4

SC-W

U

C32

SC-L3

CH11

CN506

1

2

CN72

red

3

P

63H1

CN801

yellow

1

2

F1,F2,F3

AC250V

6.3A T

21

OFF

SW4

10

CNT02

1

CN3D

432

1

21

CPU power

supply circuit

CNAC

red

2

1

F01

AC250V

3.15A T

1

t

CN507

red

ONOFF

10

SWU1

white

CN213

red

SC-L2

3

Z24

7

4

3

2121

1

CN83

31

3

1

CNTYP5

green

21S4a

U

X02

X03

5

1

7

CN4

CN6

IGBT

4

SC-P1

FT-P

black

C30

red

Diode

Bridge

CT3

72C

C1

CN2

R1

black

TB22

3

RSH1

CN102

3

R6

C17

1

1

63LS

ZNR1

U

L

Noise

Filter

X08

3

1

CN6

yellow

red

SV4a

X07

3

5

6

4

3

2

CNLVA

CNLVB

red

CNLVC

red

1

2

3

4

5

6

white

black

SV1a

1

G

Ground

6

5

4

3

2

1

6

G

5

4

G

3

2

1

2

L1 L2 L3

1

CN215

black

L3

MF1 Fan motor(Radiator panel)

SV1a

SV4a,b,d

HIC bypass,Controls refrigerant

flow in HIC circuit

Heat exchanger capacity control

For opening/closing the bypass

circuit under the O/S

LEVINV Heat exchanger for inverter

SV7a,b Heat exchanger capacity control

For opening/closing the bypass

circuit

LEV2a,b

Pressure control,Refrigerant flow

rate control

<Symbol explanation>

63HS1

SV9

21S4a 4-way valve

Explanation

Symbol

63H1

63LS

Pressure

sensor

Pressure

switch

High pressure protection for the

heat source unit

High pressure

Low pressure

72C Magnetic relay(inverter main circuit)

Current sensor(AC)

Crankcase heater(for heating the compressor)CH11

CT12,22,3

Solenoid

valve

Linear

expansion

valve

LEV1

DCL DC reactor

Power

failure

detection

circuit

1

2

3

4

5

6

orange

3

Pump Interlock

Operation

ON signal

*7

TB8

1

blue

4

yellow

4

1

red

CNAC4

CNPW

blue

2

25613

CNOUT1

yellow

4

CNOUT2

yellow

5

X12

1

X06

M

㨪

X14

6

CN510

yellow

blue

CN63PW

421

1

5

MF1

SV7a

6

CN509

blue

THINV

t

°

CNTYP1

black

1

2

SV7b

t°

TH8

LEVINV

SV4d

1

SV4b

1

2

M

1

CN992

yellow

24

75

CNLVE

6

5

4

3

2

1

5

RELAY Board

CN

TYP

black

3

1

CNTYP2

black

1

3

*1.Single-dotted lines indicate wiring not supplied with the unit.

*2.Dot-dash lines indicate the control box boundaries.

*3.Refer to the Data book for connecting input/output signal connectors.

*4.Daisy-chain terminals (TB3) on the heat source units in the

same refrigerant system together.

*5.Faston terminals have a locking function.

Make sure the terminals are securely locked in place after insertion.

Press the tab on the terminals to remove them.

*6.Control box houses high-voltage parts.

Before inspecting the inside of the control box,turn off the power,

keep the unit off for at least 10 minutes, and confirm that the voltage

between FT-P and FT-N on INV Board has dropped to DC20V or less.

*7.Refer to the Data book for wiring terminal block for

Pump Interlock and Operation ON signal.

LED1

Display

setting