[ IX Troubleshooting ]

- 269 -

HWE09080 GB

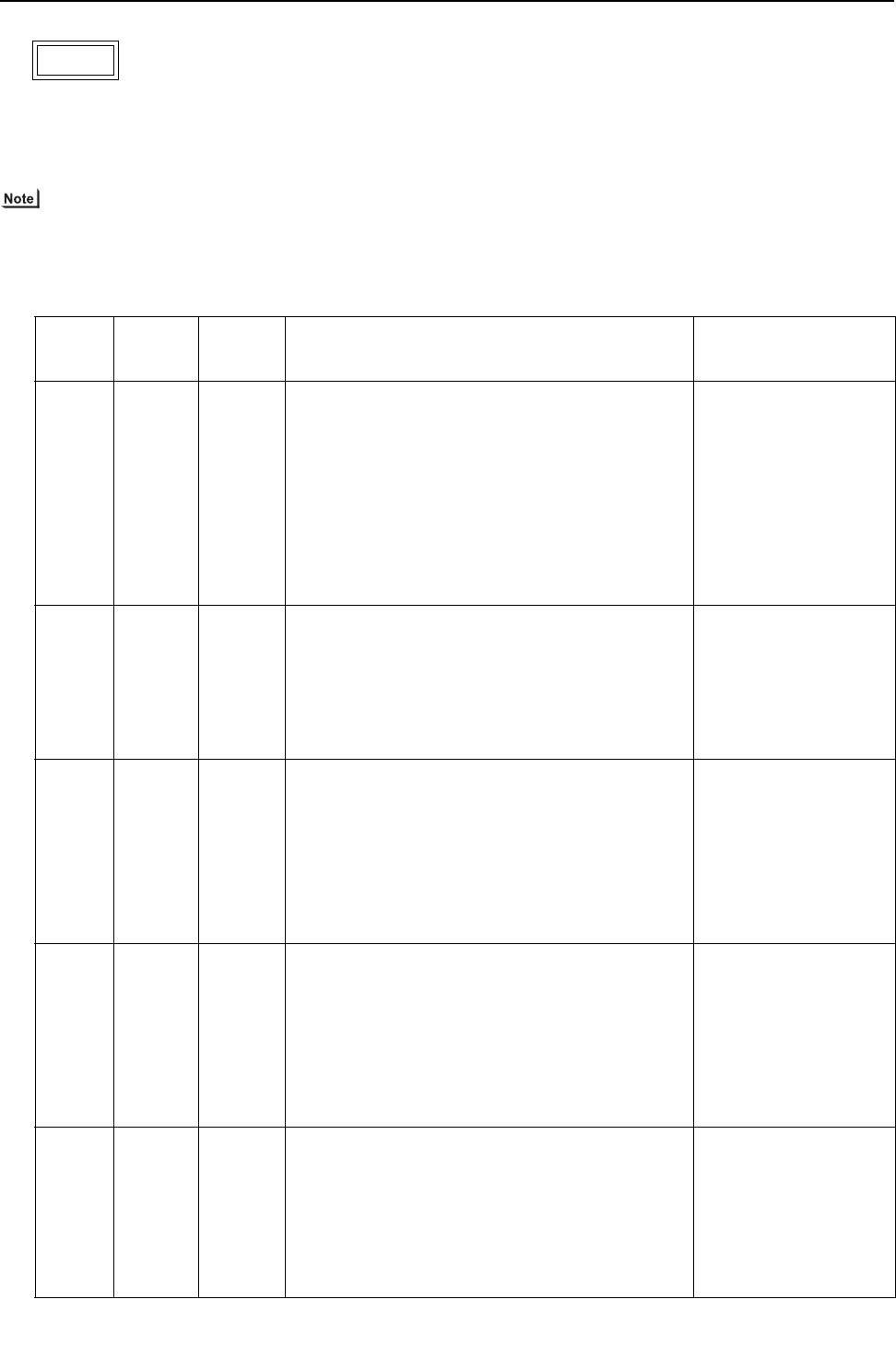

1. Error Code

No ACK error

2. Error definition and error detection method

The error is detected when no acknowledgement (ACK signal) is received after the transmission. (eg. When the data is trans-

mitted six times in a row with 30 seconds interval, the error is detected on the transmission side.)

The address/attribute appeared on the display on the remote controller indicates the controller which did not provide

the response (ACK).

3. System configuration

(1) System with one heat source unit

6607

Error

source

address

Error dis-

play

Detection

method

Cause Check method and remedy

Heat

source

unit (OC)

ME re-

mote con-

troller

(RC)

MA re-

mote con-

troller

(MA)

No ac-

knowl-

edgement

(ACK) at

IC trans-

mission to

OC

(1) Contact failure of transmission line of OC or IC Turn off the power

source of the heat

source unit, and turn it

on again.

If the error is accidental,

it will run normally. If not,

check the causes (1) -

(4).

(2) Decrease of transmission line voltage/signal by ex-

ceeding acceptable range of transmission wiring.

Farthest:200 m [656ft] or less

Remote controller wiring:

10m [32ft] or less

(3) Erroneous sizing of transmission line (Not within the

range below). Wire diameter:

1.25mm

2

[AWG16] or more

(4) Heat source unit control board failure

BC con-

troller

(BC)

ME re-

mote con-

troller

(RC)

MA re-

mote con-

troller

(MA)

No ac-

knowl-

edgement

(ACK) at

IC trans-

mission to

BC

(1) When BC controller address is changed or modified

during operation.

Turn off the heat source-

indoor units for 5 or

more minutes, and turn

them on again.

If the error is accidental,

they will run normally. If

not, check the causes

(1) - (4).

(2) Faulty or disconnected transmission wiring of BC

controller

(3) Disconnected connector of BC controller (CN02)

(4) Faulty control board of BC controller

Indoor

unit (IC)

ME re-

mote con-

troller

(RC)

MA re-

mote con-

troller

(MA)

No ac-

knowl-

edgement

(ACK) at

RC trans-

mission to

IC

(1) When IC unit address is changed or modified during

operation.

Turn off the heat source-

indoor units for 5 or

more minutes, and turn

them on again.

If the error is accidental,

they will run normally.

If not, check the causes

(1) - (5).

(2) Faulty or disconnected IC transmission wiring

(3) Disconnected IC connector

(CN2M)

(4) Indoor unit controller failure

(5) ME remote controller failure

LOSS-

NAY

(LC)

ME re-

mote con-

troller

(RC)

MA re-

mote con-

troller

(MA)

No ac-

knowl-

edgement

(ACK) at

IC trans-

mission to

LC

(1) The power source of LOSSNAY has been shut off. Turn off the power

source of LOSSNAY

and turn it on again.

If the error is accidental,

it will run normally.

If not, check the causes

(1) - (5).

(2) When the address of LOSSNAY is changed in the

middle of the operation

(3) Faulty or disconnected transmission wiring of

LOSSNAY

(4) Disconnected connector (CN1) on LOSSNAY

(5) Controller failure of LOSSNAY

ME re-

mote

control-

ler (RC)

ME re-

mote con-

troller

(RC)

MA re-

mote con-

troller

(MA)

No ac-

knowl-

edgement

(ACK) at

IC trans-

mission to

RC

(1) Faulty transmission wiring at IC unit side. Turn off the power

source of the heat

source unit for 5 minutes

or more, and turn it on

again.

If the error is accidental,

it will run normally.

If not, check the causes

(1) - (4).

(2) Faulty wiring of the transmission line for ME remote

controller

(3) When the address of ME remote controller is

changed in the middle of the operation

(4) ME remote controller failure