739

FX3S/FX3G/FX3GC/FX3U/FX3UC Series

Programming Manual - Basic & Applied Instruction Edition

33 Extension File Register Control – FNC290 to FNC299

33.6 FNC295 – INITER / Initialize ER

31

FNC277-FNC279

Data

Transfer 3

32

FNC280-FNC289

High-Speed

Processing 2

33

FNC290-FNC299

Extension File

Register Control

34

FNC300-FNC305

FX

3U

-CF-ADP

35

SFC•STL

Programming

36

Interrupt

Function

37

Special Device

38

Error Code

A

Version Up

Information

B

Execution Times

Operation

• Extension file registers (ER) [inside the memory cassette]

Caution

About 25 ms is required to initialize one sector.

When initializing two or more sectors, take either measure shown below.

• Set a large value to the watchdog timer D8000 using the following program

Guideline of the watchdog timer set value

A value acquired by the following procedure can be regarded as the guideline of the watchdog timer set value.

If an acquired value is 200 ms or less, however, it is not necessary to change the watchdog timer set value.

1) Write a program to be executed from GX Works2 to the PLC.

[Online]→[Write to PLC...]

2) Set the current value of D8000 (unit: ms) to "1000" using the [Modify Value] function in GX Works2.

[Debug]→[Modify Value]

3) Set the PLC mode to RUN, and execute the program. (Execute this instruction also.)

4) Monitor the maximum scan time D8012 (unit: 0.1 ms) using the device/buffer memory batch monitor function in

GX Works2.

5) Set the watchdog timer to the maximum scan time (D8012) or more.

D8012 stores the maximum scan time in increments of 0.1 ms.

Rough guide to the watchdog timer set value D8000 (unit: ms) is the "value stored in D8012 divided by 10" added

by 50 to 100.

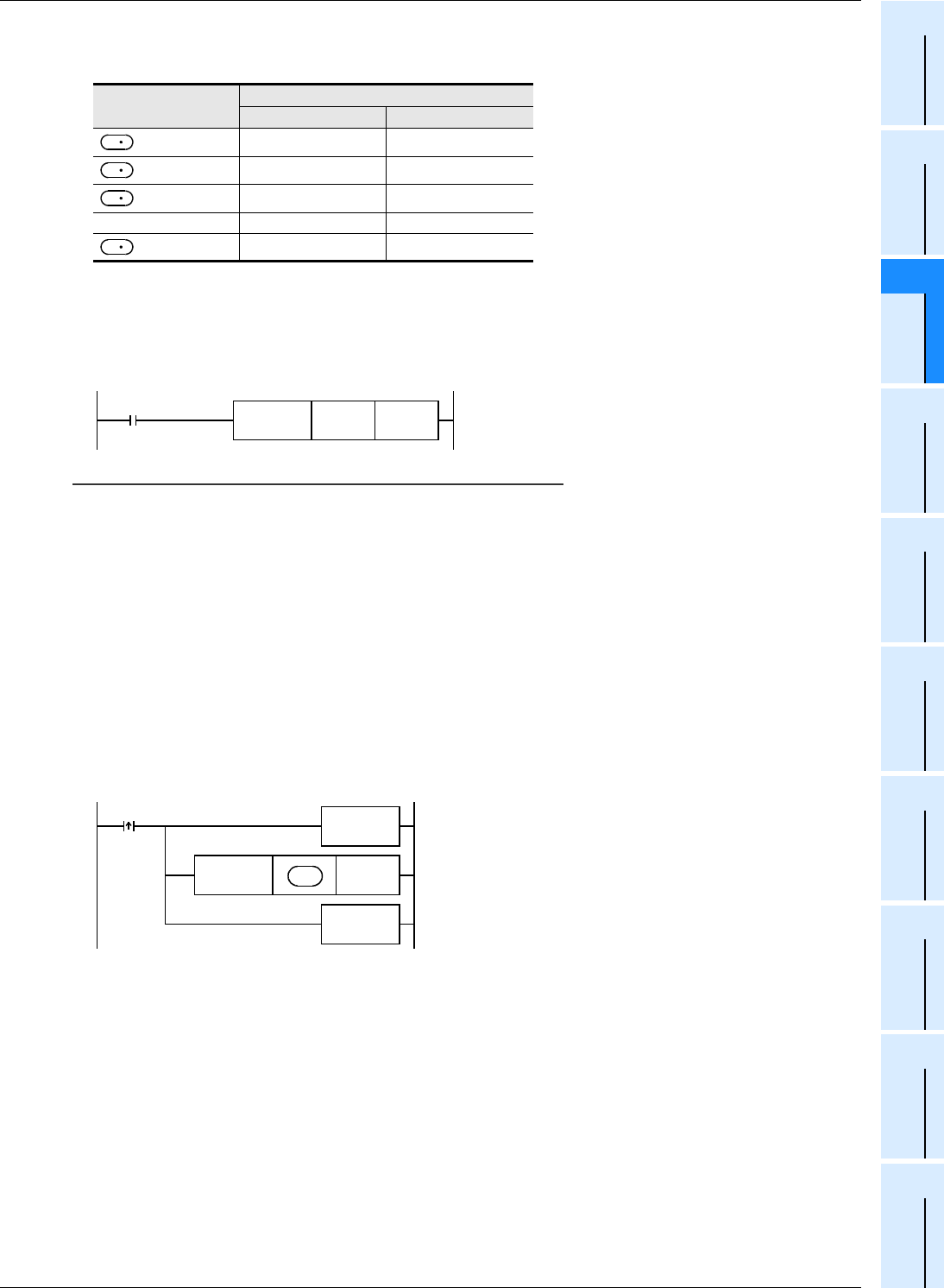

• Setting the WDT (FNC 07) instruction just before and after the INITER instruction as shown below:

If the processing time of the INITER command exceeds 200 ms, set the watchdog timer value D8000 (unit: ms) to the

processing time or more.

2. Allowable number of writes to the memory

Note the following cautions on access to extension file registers.

• Data can be written to the memory cassette (flash memory) up to 10,000 times.

Every time the INITR (FNC292), RWER (FNC294) or INITER (FNC295) instruction is executed, it is counted as a

write to the memory. Make sure not to exceed the allowable number of writes.

When a continuous operation type instruction is used, data is written to the memory in every operation cycle of the

PLC. To prevent this, make sure to use a pulse operation type instruction.

• Execution of the LOADR (FNC290), SAVER (FNC291) or LOGR (FNC293) instruction is not counted as a write to

the memory. However, it is necessary to initialize the writing target sector before executing the SAVER (FNC291)

or LOGR (FNC293) instruction.

Every time the INITR (FNC292) or INITER (FNC295) instruction is executed, it is counted as a write to the memory.

Make sure not to exceed the allowable number of writes.

Device number

Current value

Before execution After execution

H1234 HFFFF

+1

H5678 HFFFF

+2

H90AB HFFFF

...

...

...

+(2048×n)-1

HCDEF HFFFF

S

S

S

S

M8002

FNC 12

MOV

K

D8000

Initial pulse

The watchdog timer is reset.

FNC295

INITER

n

FNC 07

WDT

FNC 07

WDT

The watchdog timer is reset.

Command

input

S