3. MOUNTING AND WIRING

3

−

7

3.4 Mounting the Serial Absolute Synchronous Encoder

Precautions when using a MR-HENC serial absolute synchronous encoder.

(1) If the serial absolute synchronous encoder is linked to a chain, timing belt, or

gears, the machine rotating shaft should be supported by a separate bearing

and connected to MR-HENC through a coupling. Ensure that excessive force

(greater than the permitted shaft load) is not applied to the encoder.

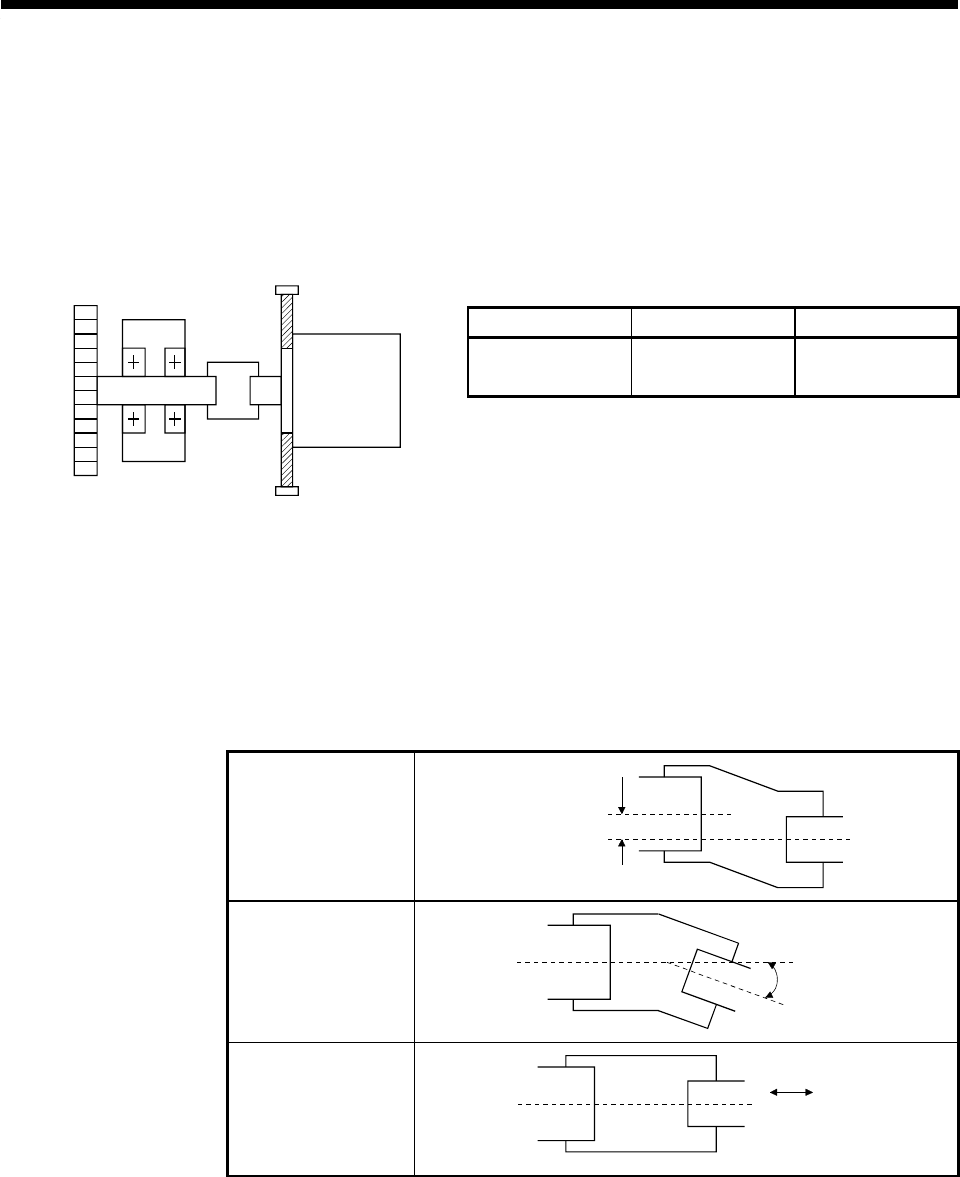

Table 3.1 Permitted Shaft Loads

Radial Direction Thrust Direction

Permitted shaft

load

98N max. 49N max.

Coupling

Bearing

Gear

MR-HENC

Fig. 3.1 Example of Encoder Linked to a Gear

(2) Large errors in eccentricity and angle of deviation during mounting can apply

an excessive force to the MR-HENC shaft, which can cause deterioration in

performance drastically reduce encoder life.

Minimize loads applied to the shaft such that they lie within the permitted shaft

load range. The permitted shaft loads are shown in Fig. 3.2 for the

recommended coupling type.

Table 3.2 Permitted Values for Coupling Mounting Errors

Eccentricity

0.2mm

(0.008 inch)

max.

Angle of deviation

1.5° max.

Axial displacement

0.5mm

(0.02 inch)

max.