5. INSPECTION AND MAINTENANCE

5

−

4

5.3 Scheduled Inspections

The inspections listed in the table below should be conducted once or twice every

6 to 12 months. They should also be conducted after equipment is moved or

upgraded, and if the wiring is changed.

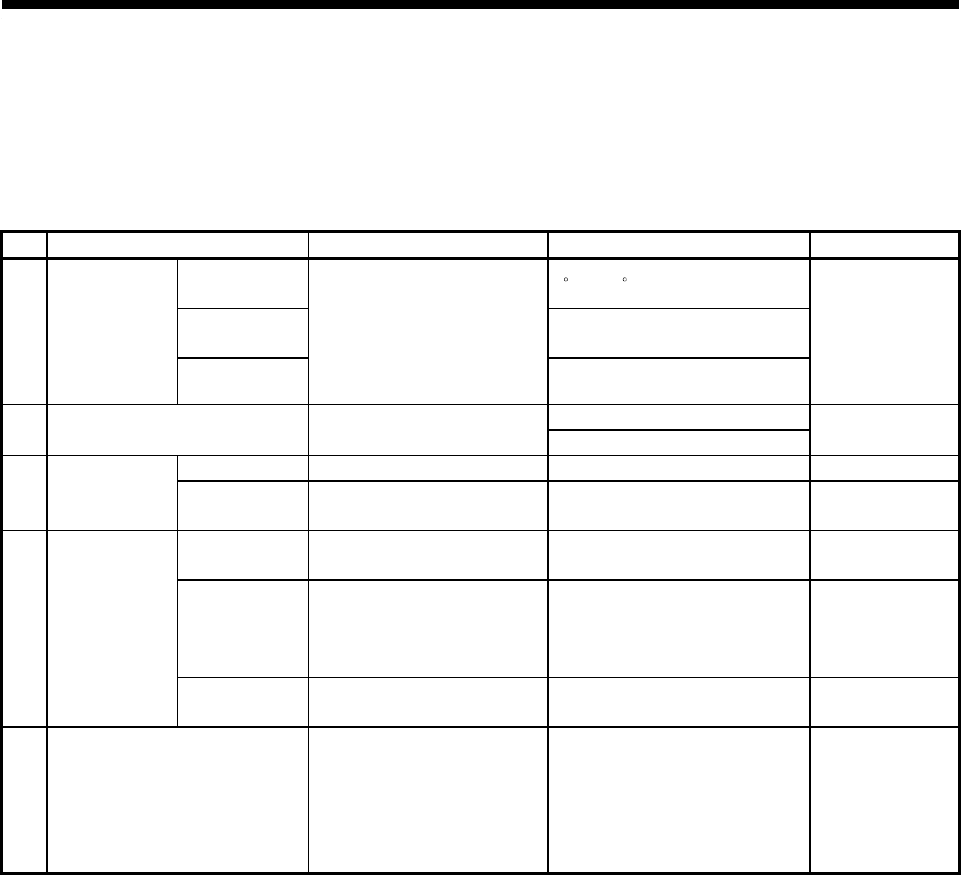

Table 5.3 Scheduled Inspections

No. Item Description Evaluation Standard Remedy

Ambient

temperature

0

C

to 55

C

Ambient

humidity

10% to 90% RH

1

Ambient

environment

Atmosphere

Measure temperature and

humidity.

Measure corrosive gases.

No corrosive gases

If system is in an

enclosure,

measure

temperature and

humidity inside the

enclosure.

85 VAC to 264 VAC

2 Supply voltage

Measure voltage across 100

VAC/200 VAC terminals.

Change power

supply

Looseness Move units and check Firmly installed Tighten screws.

3 Installation

Dirt, foreign

matter

Visual No dirt or foreign matter Clean

Loose terminal

screws

Turn with a screwdriver No loose screws

Tighten loose

screws

Spacing

between

solderless

terminals

Visual Correct spacing is maintained Adjust spacing

4 Connections

Loose

connectors

Visual Connectors fully tightened

Tighten connector

screws

5Battery

In monitor mode, check from

peripheral device that M9006

and M9007 are OFF.

(Preventative maintenance)

Replace battery if

life is exceeded,

even if no voltage

drop occurs.

Refer to Section

5.3.1.