5. INSPECTION AND MAINTENANCE

5

−

7

5.4 Troubleshooting

This section describes the errors which could occur when using the system and

what to do about them.

Refer to the appropriate software package operating manual for information on the

error messages displayed during peripheral device operation.

When an error occurs, the system status can be determined by checking the

equipment where the error occurred, from the error codes, or by monitoring with a

peripheral device. To quickly recover from an error, use the appropriate method to

determine the cause of the error.

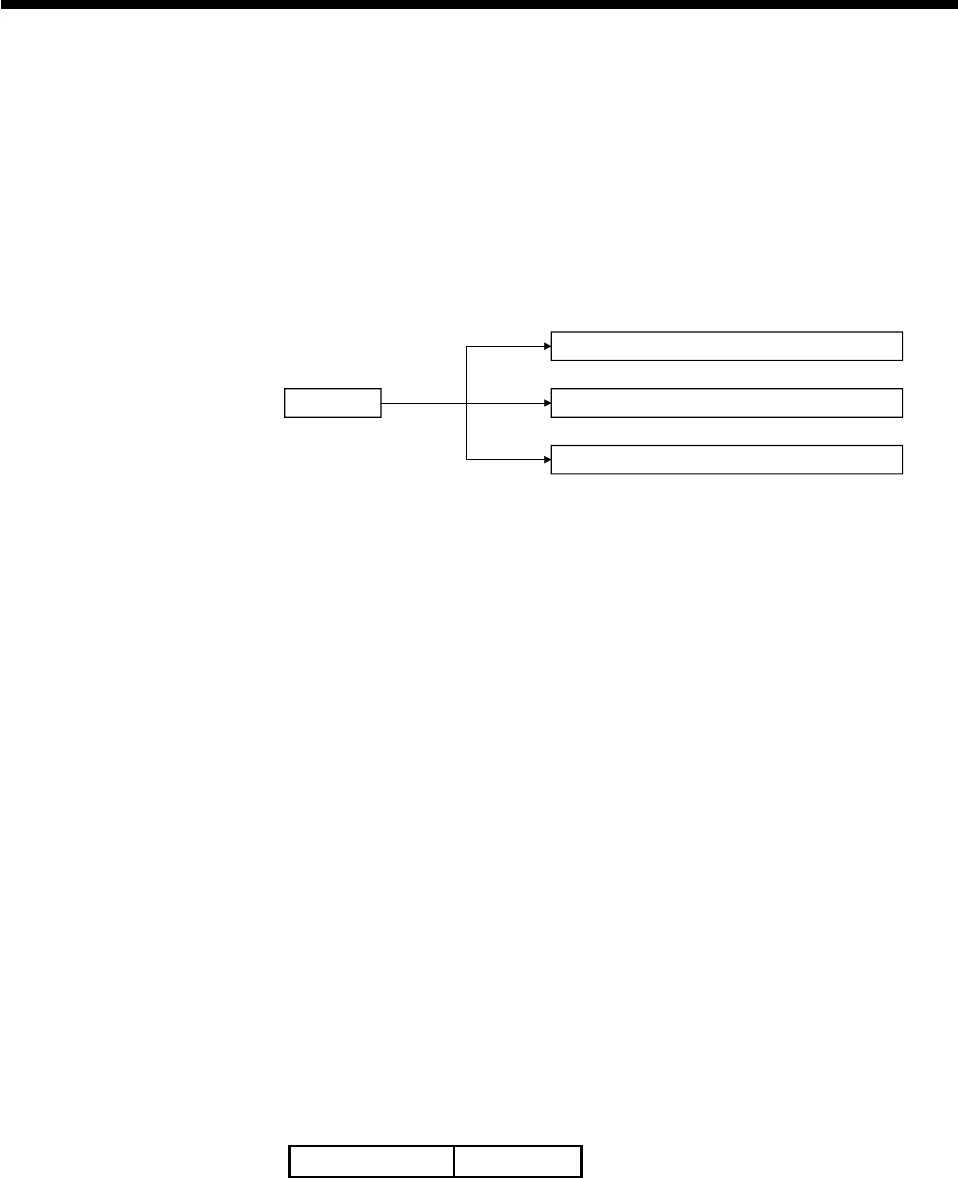

Error occurs

Check the equipment where the error occurred

Check from the error code

Check by monitoring from a peripheral device

(1) Checking the equipment where the error occurred

Visually determine the cause of the error from the indicators on the front of the

module, from the operating status of the equipment, etc.

(a) Machine motion (stop status, operating status)

(b) Whether power is on or off

(c) Status of I/O equipment

(d) Wiring status (I/O wires, cables)

(e) Display states of various indicators (e.g. POWER LED, RUN LED, ERROR

LED, I/O LED)

(f) Setting states of various setting switches (e.g. extension base, power failure

compensation)

After checking (a) to (f), connect the peripheral device and check the CPU

module's operating status and program data.

(2) Checking the error codes

Determine the cause of the error by monitoring the error codes stored when the

error occurred.

The error code storage devices are listed below.

Refer to the appropriate operating system programming manual for

descriptions of the error codes.

(a) Error codes during sequence control

Refer to Section 5.4.1 (10) “Table of Error Codes” for descriptions of the

error codes.

Error code D9008

(b) Error codes during motion control

For error storage devices in motion control, refer to the programming manual of

the corresponding OS.