4. TRIAL RUN AND ADJUSTMENT

4

−

8

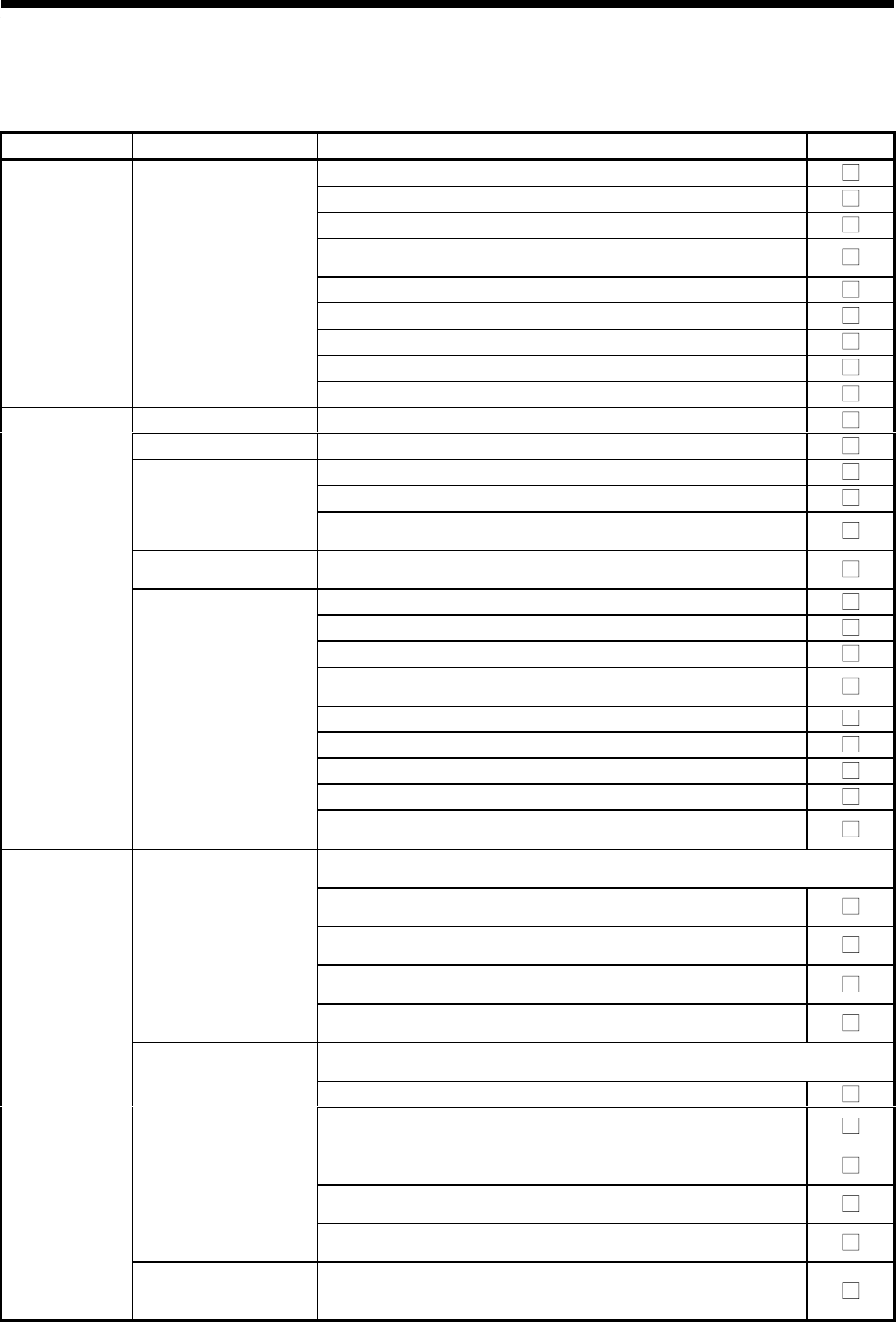

4.4 Trial Run and Adjustment Checklist

At the worksite, copy the following table for use as a check sheet.

Work Step Item Trial Run and Adjustment Confirmation Check

Check that each module is mounted properly.

Check that each connector is fitted properly.

Check each terminal screw for looseness.

Check that earth wires of power supply module, servo

amplifiers, etc. are normal.

Check that motor wiring is proper.

Check that regenerative brake option wiring is proper.

Check that emergency stop circuit is proper.

Check that teaching unit's deadman switch wiring is proper.

Before

power-on

Unit/module mounting

and basic wiring

Check that each power supply wire and each I/O wire is proper.

OS installation Check that the motion OS installed is compatible.

Positioning parameters Check that each positioning parameter value is proper.

Check that upper and lower stroke limit inputs are normal.

Check that STOP signal input is normal.

A172SENC external

signals

Check that near-zero point dog and speed-position change

signal inputs are normal.

Program/positioning

data

Check that motion program, sequence program and positioning

data are stored in CPU module normally.

Check that communications with servo amplifiers can be made.

Check that rotation direction for JOG operation is normal.

Check that upper and lower limit switches operate normally.

Check that rotation at maximum command speed is not more

than motor rating.

Check that JOG operation moves machine normally.

Check that a stop is effected at stroke limit.

Check that an emergency stop is made.

Check that home position return is made normally.

Power-on

CPU module in

STOP status

Basic axis operations

(Check each axis)

Check that each positioning control of motion program is

exercised normally.

Check each operation in manual operation mode of system with sequence

program running.

Check that machine operation is stopped immediately by

emergency stop.

Check operation of each actuator and operation confirmation

limit switch.

Check that emergency stop and equipment alarm signals are

given properly.

Manual operation

Make other checks in compliance with control specifications

specific to system and equipment.

Check each operation in automatic operation mode of system with

sequence program running.

Check a sequence of automatic operation motions.

Check that machine operation is stopped immediately by

emergency stop.

Check that module or equipment alarm causes an immediate

stop or cycle stop.

Check that restoring operation can be performed after an alarm

stop.

Automatic operation

Make other checks in compliance with control specifications

specific to system and equipment.

CPU module in

RUN status

Torque check

Check the acceleration/deceleration torque is not more than

maximum torque.

Check that continuous load torque is rated torque.