1. SPECIFICATIONS OF MOTION SYSTEM COMPONENTS

1

−

46

•

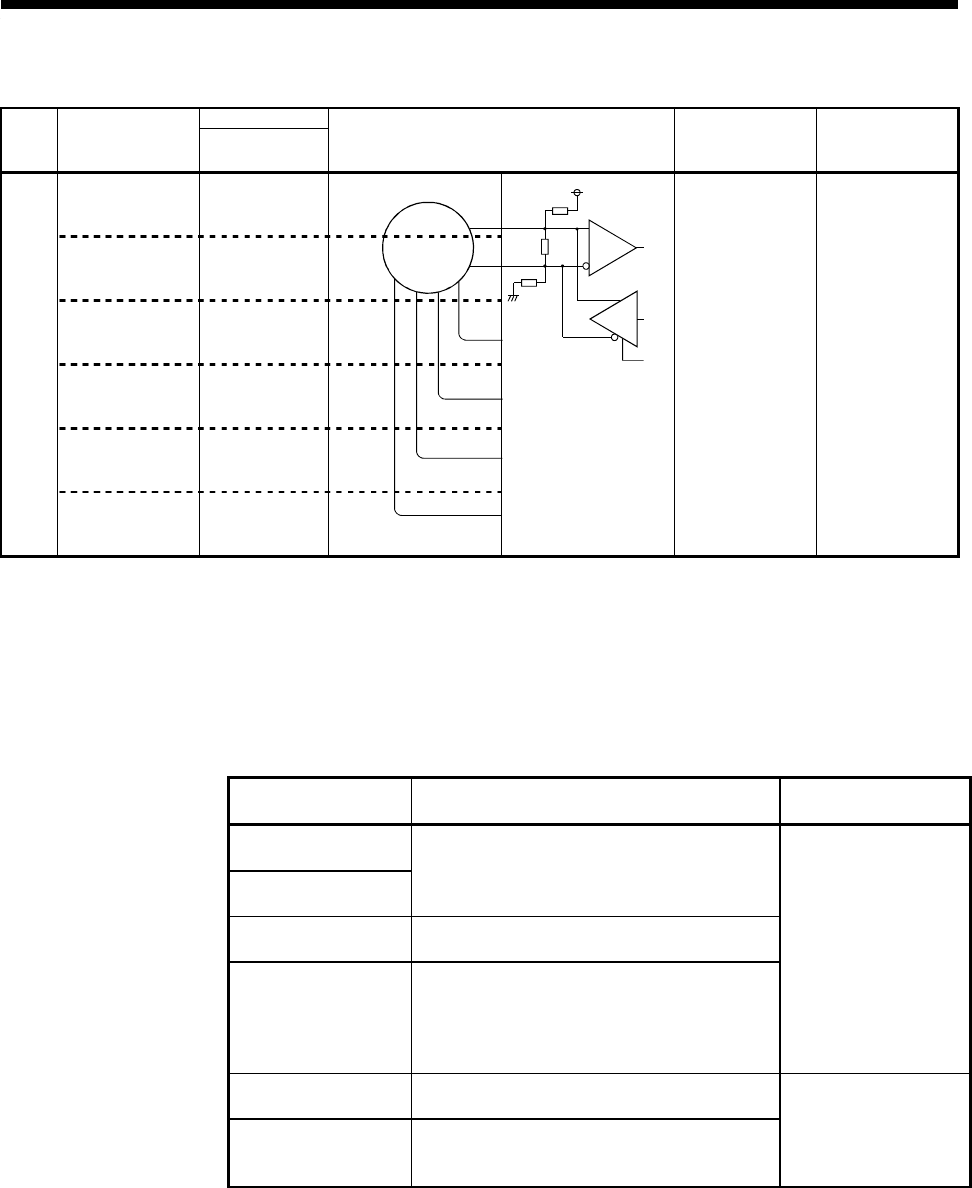

Interface between SY.ENC connector and external equipment

Pin No.

Input or

Output

Signal Name

SY.ENC

Connector

Wiring Example Internal Circuit Specification Description

MR

4

MRR

3

P5

*3

7, 8, 16

SG

*3

1, 2, 15, 17

BAT

14

Input

SD

20

•

Transmission

method: serial

communications

•

Position detection

method: absolute

*3: Connect when using MR-HSCBL10M to MR-HSCBL30M.

(c) Connection of servo external signals

There are the following servo external signals.

The A172SENC is assigned a set of input numbers per axis, with the exception

of the tracking enable signal and electromagnetic brake command output. Make

the system settings of the positioning software package to determine the I/O

numbers corresponding to the axis No.s.

Servo External

Signal

Application

Number of Points on

One A172SENC

Upper stroke limit

input (FLS)

Lower stroke limit

input (RLS)

For detection of upper and lower stroke

limits

Stop signal input

(STOP)

For stopping under speed or positioning

control

Near-zero point

dog/speed-position

change input

(DOG/CHANGE)

For detection of near-zero point dog at

near-zero point dog or count type home

position return or for switching from speed

to position under speed-position change

control.

8 points each

(1 point/1 axis each)

Tracking enable

signal input

Synchronous encoder input start signal

Electromagnetic

brake command

output

For command output to electromagnetic

brake

1 point each

Serial

synchronous

encoder