58

SECTION IV - INSTALLATION INSTRUCTIONS

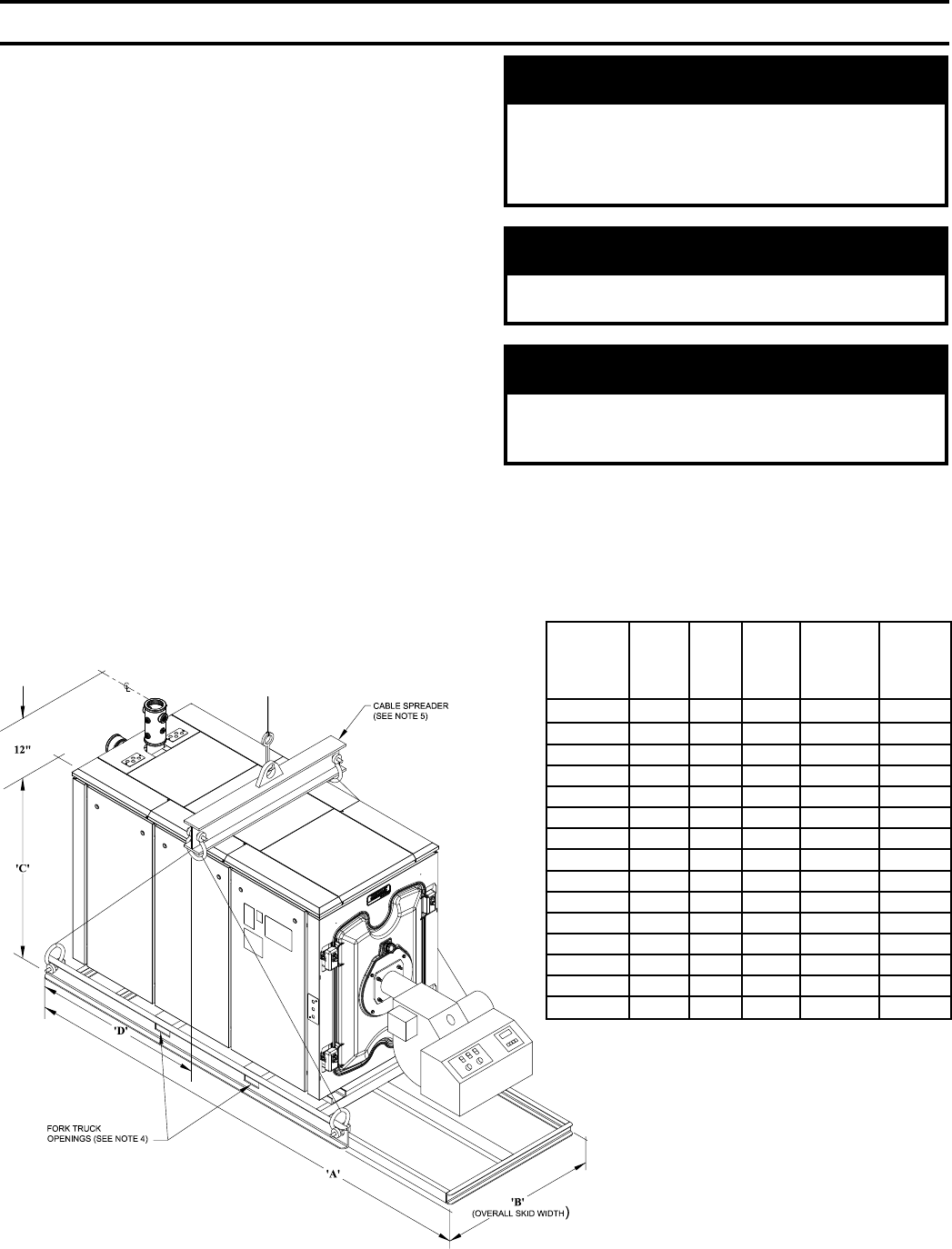

Packaged Boiler Shipping Information

Figure 48: Packaged Boiler Shipping Information

1. The packaged boiler comes on its own shipping

skid (see Figure 48) and the assembled block is

hydrostatically tested at the factory. Once the boiler

is in its nal position, PERFORM ANOTHER

HYDROSTATIC TEST AT 1½ TIMES THE

WORKING PRESSURE OF THE BOILER (see

Section II, Paragraph C). The shipping skid can be

used as a housekeeping pad unless local codes say

otherwise. Most controls are pre-wired down to the

burner. If burner is equipped with a lead lag panel,

lead lag controls will be shipped loose for header

mounting. The power can be supplied to the burner

if equipped with a control panel. If burner has no

panel, the power must be supplied to a junction box

near the front of the boiler.

2. If the boiler burner unit was factory re tested,

the burner was adjusted to approximately 10.2%

CO2 (gas) or 13.2% CO2 (oil) with an overre

pressure as listed in Table II of this manual. Final

adjustments should be made once the unit is

installed.

CONNECT SUPPLY AND RETURN PIPING TO

HEATING SYSTEM (see Figures 49a, 49b, 50a and

50b).

WARNING

Failure to properly pipe boiler may result in

improper, unsafe system operation and void

manufacturer’s warranty.

DO NOT improperly pipe boiler.

WARNING

All hot water pipes must have clearances of at

least 1/2” from all combustible construction.

WARNING

A hot water boiler installed above radiation level

must be provided with a low water cutoff device

as part of the installation.

1. HOT WATER HEATING - This boiler must be

installed in strict accordance to the instructions

found in this installation manual. Deviations

from these installation instructions may void

manufacturer’s warranty.

* Width can vary with gas train conguration.

** Varies slightly with burner and gas train conguration.

1.

Do not tilt. Exercise caution when lifting to avoid

damage.

2.

This boiler can be lifted by fork truck. Do not truck from

front.

3.

When lifting from rear, forks must extend from beyond

center of gravity and second skid cross bar.

4.

When lifting from side, forks must extend to opposite

skid rail and straddle center of gravity.

5.

Cablespreader is to prevent jacket damage. Spreader

width should equal B (width of skid) + 12”. Adjust cable

lengths to lift at approximate center of gravity per chart.

Number of

Sections

Length

A

(Inch)

Width

B *

(Inch)

Height

C

(Inch)

Approx.

Center of

Gravity D

** (Inch)

Approx.

Shipping

Weight

(Lbs.)

4 77½ 48 61½ 23¼ 2789

5 83½ 48 61½ 26¼ 3272

6 95½ 48 61½ 29¼ 3755

7 101¾ 48 61½ 32½ 4249

8 108 48 61½ 35½ 4783

9 114 48 61½ 38½ 5261

10 130¼ 48 61½ 44½ 5757

11 136½ 48 61½ 47¾ 6236

12 142½ 48 61½ 50¾ 6739

13 148½ 48½ 61½ 53¾ 7227

14 154¾ 48½ 63½ 57 7760

15 161 48½ 63½ 60 8335

16 167 48½ 63½ 63 8824

17 173 48½ 63½ 66 9324

18 179¼ 48½ 63½ 69¼ 9823