53

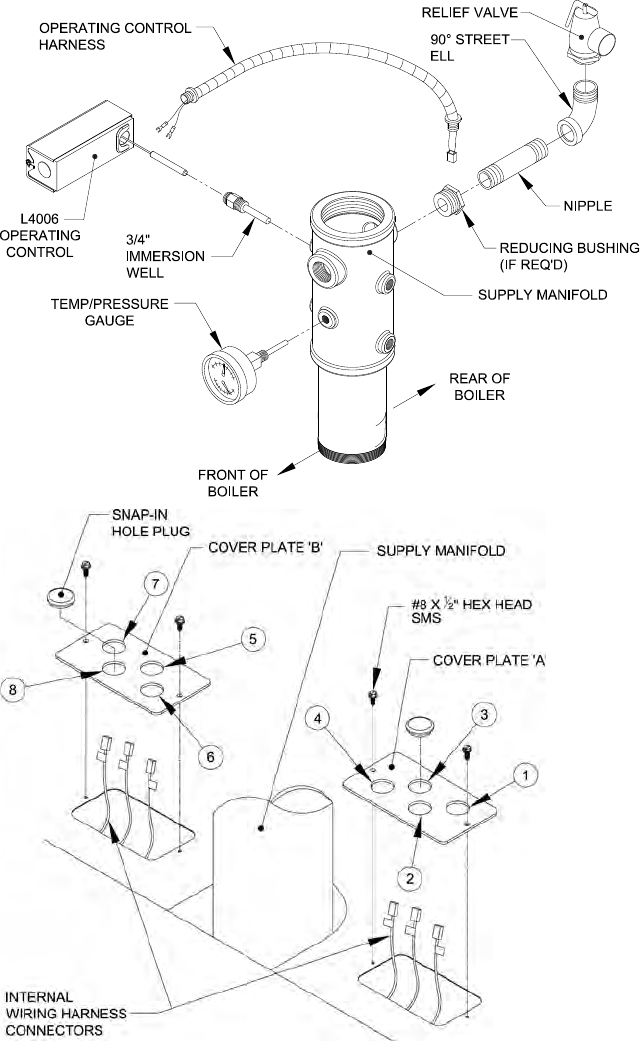

Note: Supply manifold must be installed with 1½”

couplings aligned with front and rear axis of boiler.

2. Apply thread sealant and install temperature/

pressure gauge into tapping ‘G’, see Figures 38 and

39. Wrench until water tight. Tighten gauge using

hex on stem, do not tighten or apply pressure to

case.

3. Apply thread sealant and install relief valve and

pipe ttings in Tapping ‘B’, see Figure 38. Fittings

should be arranged as shown in Figure 39. By code,

relief valve must be installed vertically. Based on

vent pipe arrangement and access, relief valve can

be installed with discharge facing a left or right.

Figure 39: Install Standard Trim and

Operating Control

4. Apply thread sealant to 3/4” immersion well

and install in tapping ‘D’ as shown in Figure 38.

Wrench well until water tight.

5. Locate L4006A Operating Control and remove

knockout on casing closest to mounting hole.

Connect end of harness with forked terminals to

casing knockout. Connect wires to terminal on limit

control, wires are interchangeable. Refer to Figure

39.

6.

Connect opposite end of L4006A Operating Control

Harness to right side junction box cover ‘A’, hole

location #1 as shown in Figure 40.

7. Locate mating connectors labeled “operating

control” inside right junction box. Join mating

Figure 40: Control Connections to

Internal Wiring Harness

connectors

which are polarized

and lock together. Lightly tug on

connectors to make sure they are

secure.

8.

If no other controls are being

installed at this time, secure Cover

‘A’ and Cover ‘B’ to jacket rear top

panel with two (2) #8 x 1/2” lg. hex

head SMS per cover. Install 7/8”

knockout plugs (provided) to all

unused holes, refer to Figure 40.