AOS WPC - Tech Training 57 of 72 Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

VF BOILER SERVICE MANUAL

ERROR MESSAGES (CONT)

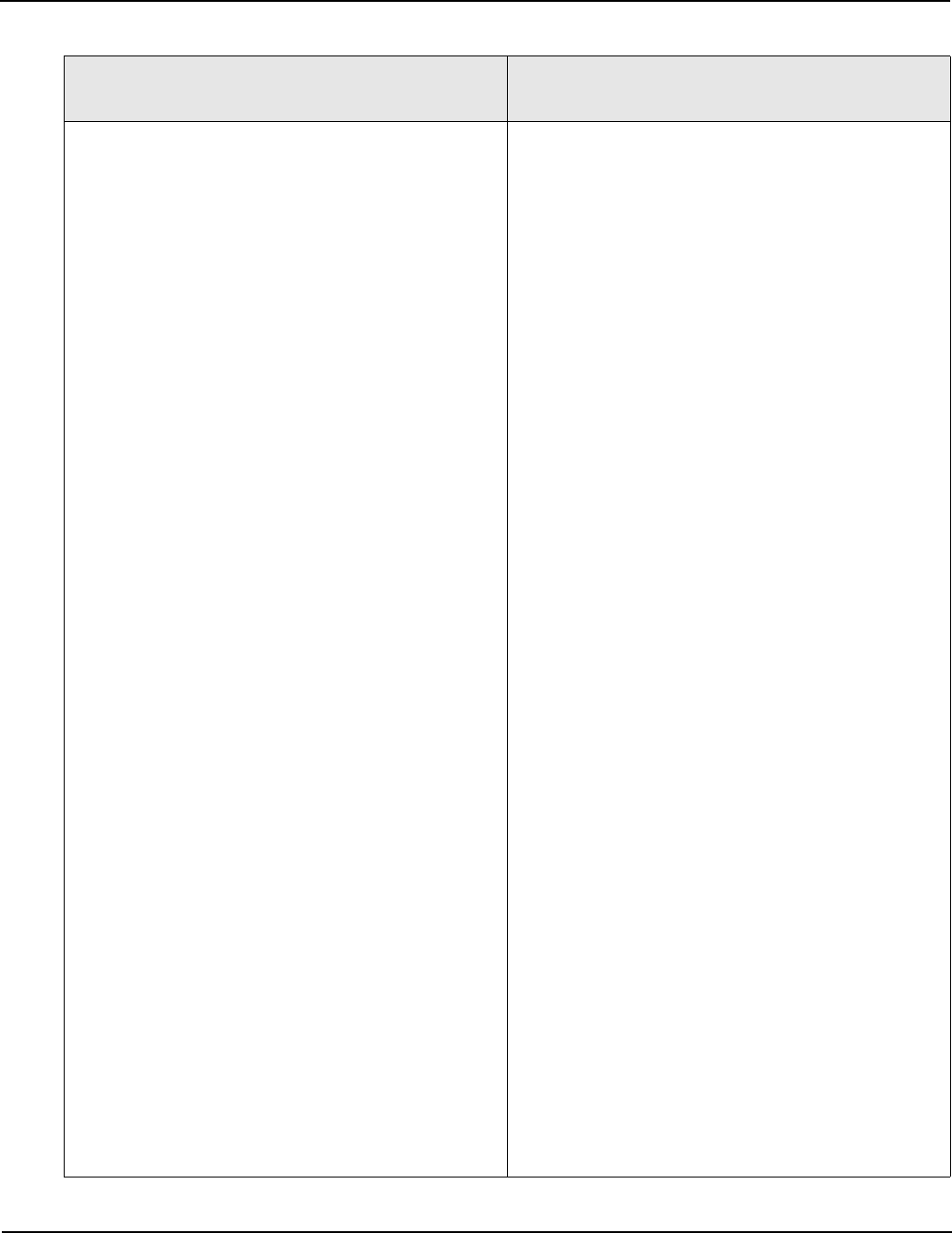

DISPLAYED MESSAGE

CONDITION/INDICATES

CHECK/REPAIR

“Flame Stg1”

Flame or ignition failure.

Error message displayed after 1 or 3 losses of flame

or after 1 or 3 failed trials for ignition. EMC 5000

control system will lock-out after 1 or 3 trials

depending on the SW1 #2 dip switch setting on the

MCB circuit board. (see page 30)

Important Service Reminder:

When performing any troubleshooting steps outlined

in this service manual always consider the wiring

and connectors between components. Perform a

close visual inspection of all wiring and connectors

to a given component before replacement.

Ensure wires were stripped before being crimped in

a wire connector, ensure wires are crimped tightly in

their connectors, ensure connection pins in sockets

and plugs are not damaged or worn, ensure plugs

and sockets are mating properly and providing good

contact.

Failure to perform this critical step or failing to

perform this step thoroughly often results in

needless down time, unnecessary parts

replacement, and customer dissatisfaction.

• Ensure the supply gas shut off valve to the

boiler and the gas train shut off valve (see

image on page 23) are both open.

• Perform the Start Up Procedure pages 17-19.

• Perform the Poor Combustion/Ignition Problems

procedures on pages 20-23.

• View the burner through the view port near the

igniter on the top of the combustion chamber

during the ignition trial period. If the burner is

igniting but the flame goes out in a few seconds

ensure the flame sensor wiring is connected

properly and in good condition.

Note: There are two flame sensors on VF boil-

ers. A single wire is connected to the J16 con-

nect on the MCB (page 29). This wire is

bifurcated (divided) into two wires and each end

then connects to one of the two flame sensors.

Repair/replace any worn or damaged wiring.

• If the flame sensor wiring is in good condition -

perform a flame sensing test. Using a DC micro

amp meter; place the meter test probes in

series with the flame sensor wire. Disconnect

the wire at the J16 connect on the MCB (page

29) insert the tip of one test probe into the wire

connector securely - touch and hold the other

test probe to the J16 connect.

Measure the flame sensing current during igni-

tion. If the flame sensing current is less than 2.5

µA - remove, inspect, and clean both flame sen-

sors. 5.0 µA flame sensing current is typical.

If either flame sensor shows signs of damage or

the ceramic insulator is cracked - replace the

flame sensor (s). If the flame sensors are in

good condition clean both sensors with fine

steel wool and reinstall both sensors. Check

flame sensing current again to see if the current

is higher and burner flame is established.

If the burner flame is still going out after a few

seconds and all the above checks and proce-

dures have been performed - call the A. O.

Smith technical information center for further

assistance at 800 527-1953.