VF BOILER SERVICE MANUAL

AOS WPC - Tech Training 52 of 72 Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

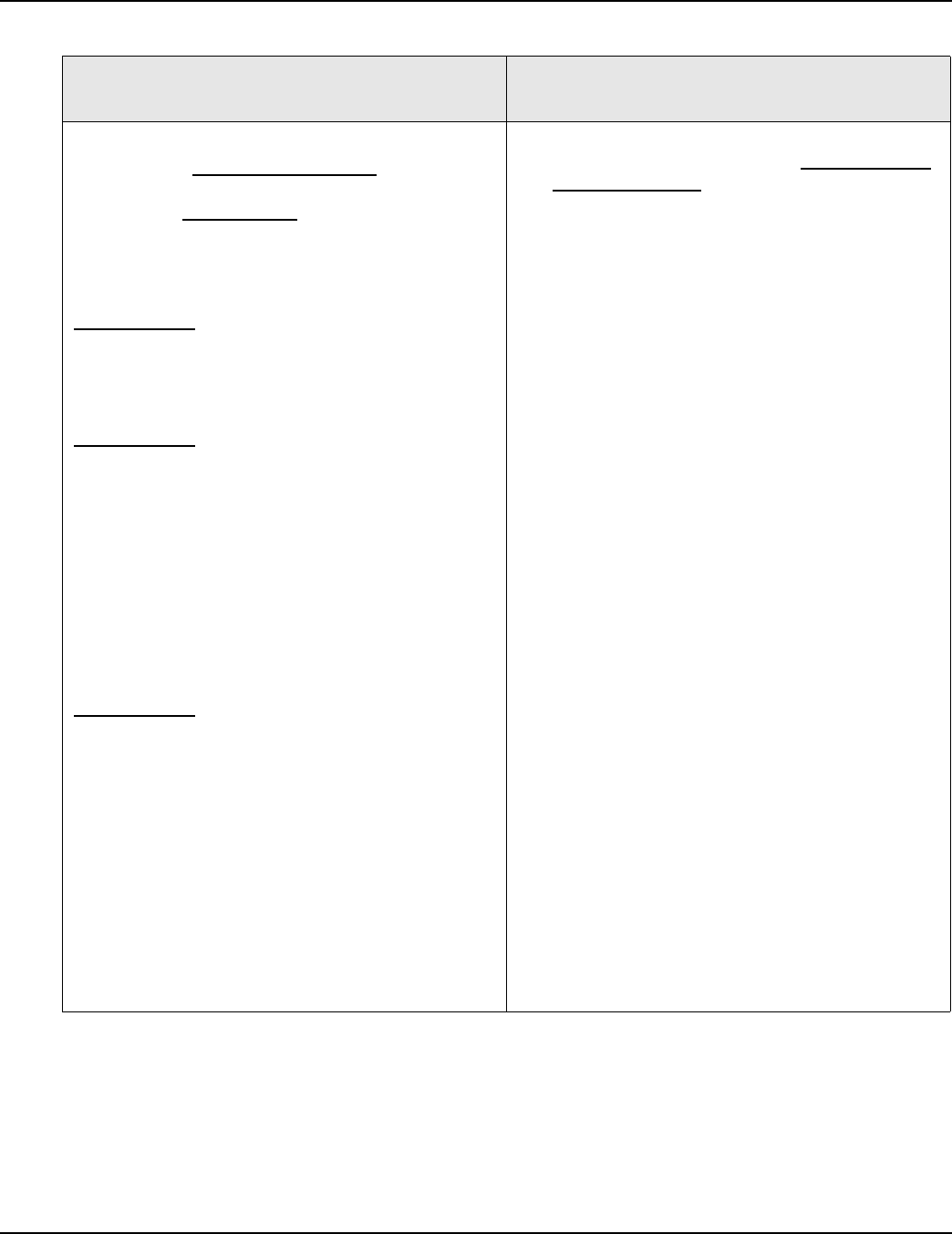

ERROR MESSAGES (CONT)

DISPLAYED MESSAGE

CONDITION/INDICATES

CHECK/REPAIR

“Blower Prov Stg1”

Blower Is Starting

(If the blower is not starting go to the “Blower Prov

Stg1” Blower Is Not Starting

tables)

Three conditions can cause this error message

when the blower is starting:

Normally Open Low Blower Prover or High Blower

Prover pressure switch contacts are not closing

during the pre or post purge operating states - or

within 5 minutes of call for heat being activated.

OR

Normally Open High Blower Prover pressure switch

contacts did not re-open after pre purge operating

state was completed. The High Blower Prover switch

is used to prove adequate purging of the combustion

chamber during pre and post purge cycles only. The

blower runs at approximately 5000 rpm during pre

and post purge operating states and at lower speeds

during all other operating states. High blower prover

switch contacts must close during the pre and post

purge states ONLY and open during all other

operating states.

OR

Normally Open Low Blower Prover pressure switch

contacts have opened during any operating state

when the blower should be running. IE: This can be

caused due to blower failure during the heating cycle

or if the pressure sensed by the switch rises above

the switches activation pressure for any reason. The

normally open contacts on both Blower Prover

switches close on a fall in pressure - the pressure

sensed must be in a vacuum.

Operational Note:

See blower prover switch information on page 24

and the Sequence of Operation on page 15.

• Ensure the sensing tubes are connected to the

“L” sensing ports on both BPS

(BPS = Blower

Prover Switches) see the control panel layout

and pressure switch information on page 24.

• Ensure all BPS sensing tubes are not kinked

and are properly connected. The two tubes from

the BPS are T fitted together and a single sens-

ing tube from this T fitting connects to a sensing

port on the gas train (the BPS sense manifold

gas pressure) - check/repair all connections.

• Ensure the blower motor wiring at the VFD

blower output terminals is wired correctly. The

blower motor wires are color coded; Black,

White, and Red. The proper connection points

on the VFD are shown on page 11. The blower

motor is 3 phase - incorrect wiring at the VFD

will cause the blower motor to run backwards

and cause this lock out condition.

• Ensure the gas train shut off valve between the

boiler’s 24 VAC gas valve and the Venturi is

open (see the image on page 23).

• Ensure the wiring to both BPS is properly con-

nected to the Com and N.O. terminals.

• Check all wiring between both BPS and the J17

socket on the MCB (page 28). Ensure the plug/

socket connectors are making good contact.

Replace/repair anything worn or damaged.

• Ensure the wiring to the Low BPS is coming

from MCB J17 pins 5 & 6 and the wiring to the

High BPS is coming from MCB J17 pins 1 & 2

see page 28.

• Ensure blower is operating at correct speed dur-

ing Igniter Warm Up period, Min Fire mode, and

Max Fire mode.

Perform Firing Rate - Modulation Performance

procedure described on pages 21 and 22.