VF BOILER SERVICE MANUAL

AOS WPC - Tech Training 50 of 72 Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

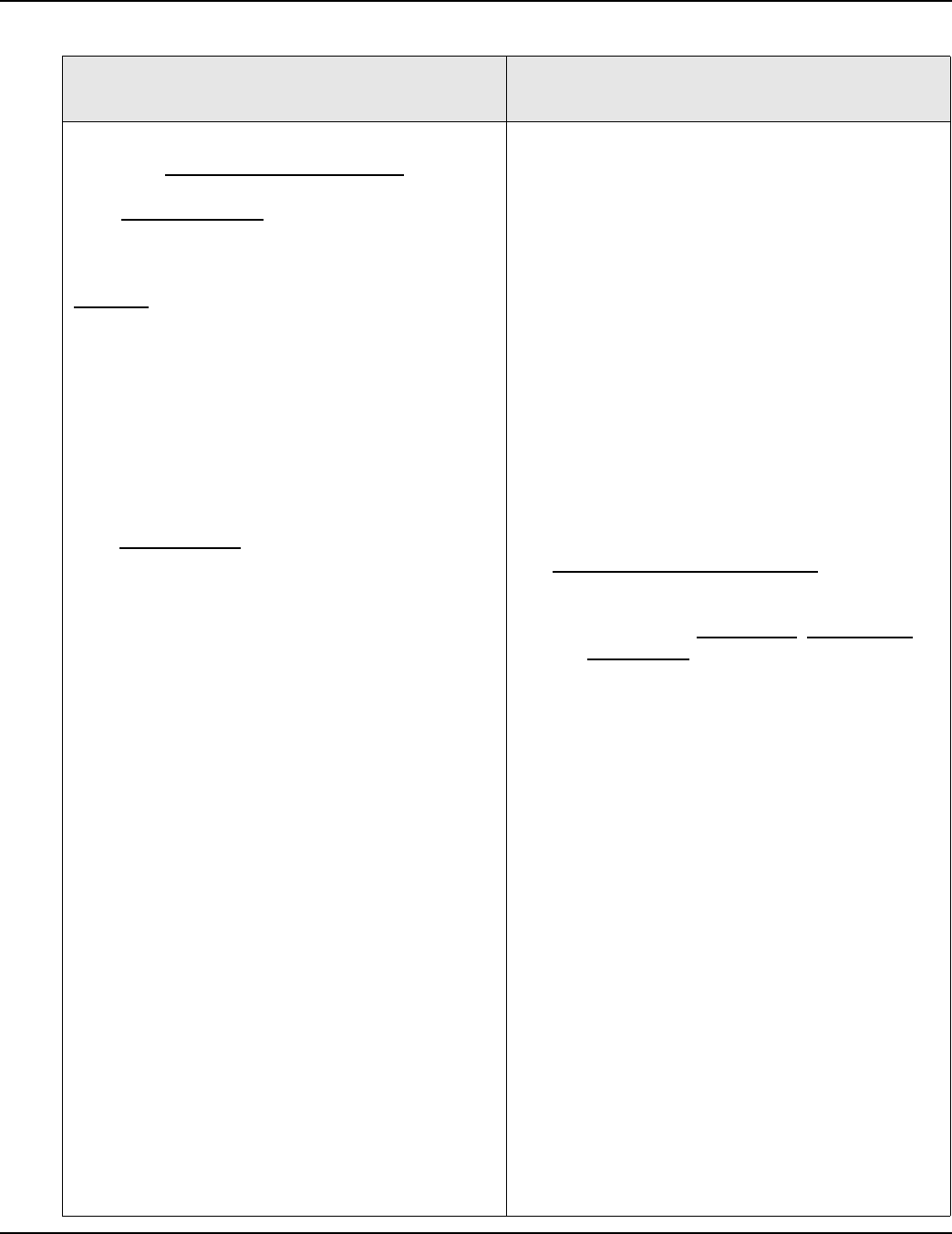

ERROR MESSAGES (CONT)

DISPLAYED MESSAGE

CONDITION/INDICATES

CHECK/REPAIR

“Blower Prov Stg1”

Blower IS NOT Starting

(If the blower is starting proceed to the “Blower Prov

Stg1” Blower Is Starting

tables)

IMPORTANT SERVICE NOTE:

BEFORE performing any of the check/repair

procedures in the right column of this table; review

the VFD and Blower Operation section in this

manual on page 11. Also review the Config Key

information on page 14 and the VFD/MCB

connections and service notes contained on page

34. Understanding how the MCB and VFD work

together to operate the blower is necessary.

Operational Note:

If the Normally Open Low Blower Prover or High

Blower Prover pressure switch contacts (circuits) are

closed at the beginning of the heat sequence prior to

the MCB initiating blower operation for the pre purge

operating state; the MCB will not initiate blower

operation in this condition - the MCB will declare a

fault condition and lock out. The “Blower Prov Stg1”

error message will be displayed on the UIM.

See blower prover switch information on page 24

and the Sequence of Operation on page 15

Important Service Reminder:

When performing any troubleshooting steps outlined

in this service manual always consider the wiring

and connectors between components. Perform a

close visual inspection of all wiring and connectors

to a given component before replacement. Ensure

wires were stripped before being crimped in a wire

connector, ensure wires are crimped tightly in their

connectors, ensure connection pins in sockets and

plugs are not damaged or worn, ensure plugs and

sockets are mating properly and providing good

contact.

Failure to perform this critical step or failing to

perform this step thoroughly often results in

needless down time, unnecessary parts

replacement, and customer dissatisfaction.

• Ensure all wiring is reconnected to the VFD and

all plugs are securely plugged into the MCB/

PDB. With power on and a call for heat acti-

vated check for a 1-10 VDC instruction from the

MCB at VFD low voltage terminals “0V” and

“AI1” - see VFD connections on page 11. See

also the Firing Rate - Modulation Performance

section on page 21 and VFD Operating Param-

eters section on page 22. Ensure you are using

a “DC” volt meter for this test. At the beginning

of a heat sequence (during pre purge) there

should be 8-9 VDC measured at these two ter-

minals. If there is not any DC voltage measured

- check/repair all wiring, sockets, and plugs

between the VFD and pins 1 & 2 of the J24

socket on the MCB see page 34.

• Check blower motor output voltage from the

VFD. This is a 3 phase power supply see page

11. With power on and a call for heat activated

perform three AC voltage checks

at the begin-

ning of the heat sequence (ensure meter is set

for AC voltage). Check between VFD Blower

Output terminals; U/T1 & V/T2

, U/T1 & W/T3,

and V/T2 & W/T3

. Actual AC voltages measured

may be between 90 and 240 VAC. The actual

amount of voltage is not important within this

range. However, all three readings should be

within 10% of each other. If no voltage is mea-

sured during any of the three voltage checks or

if any one or two measurements were signifi-

cantly lower AND all other MCB/VFD test results

above were successful - replace the VFD.

• If the VFD output to blower motor test above

showed consistent voltage between 90 and 240

AC volts during all three checks and the blower

motor still does not start - check all wiring

between the VFD blower output terminals and

the blower motor. Repair/replace any worn or

damaged wiring.

• If all wiring to blower motor from the VFD is in

good condition and the blower will not start with

correct AC voltage applied: Ensure the blower

motor IS NOT hot to the touch. If the blower

motor is cold to the touch at this point - replace

the blower.

If the motor is hot to the touch at this point pro-

ceed to the next check/repair procedure.