AOS WPC - Tech Training 53 of 72 Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

VF BOILER SERVICE MANUAL

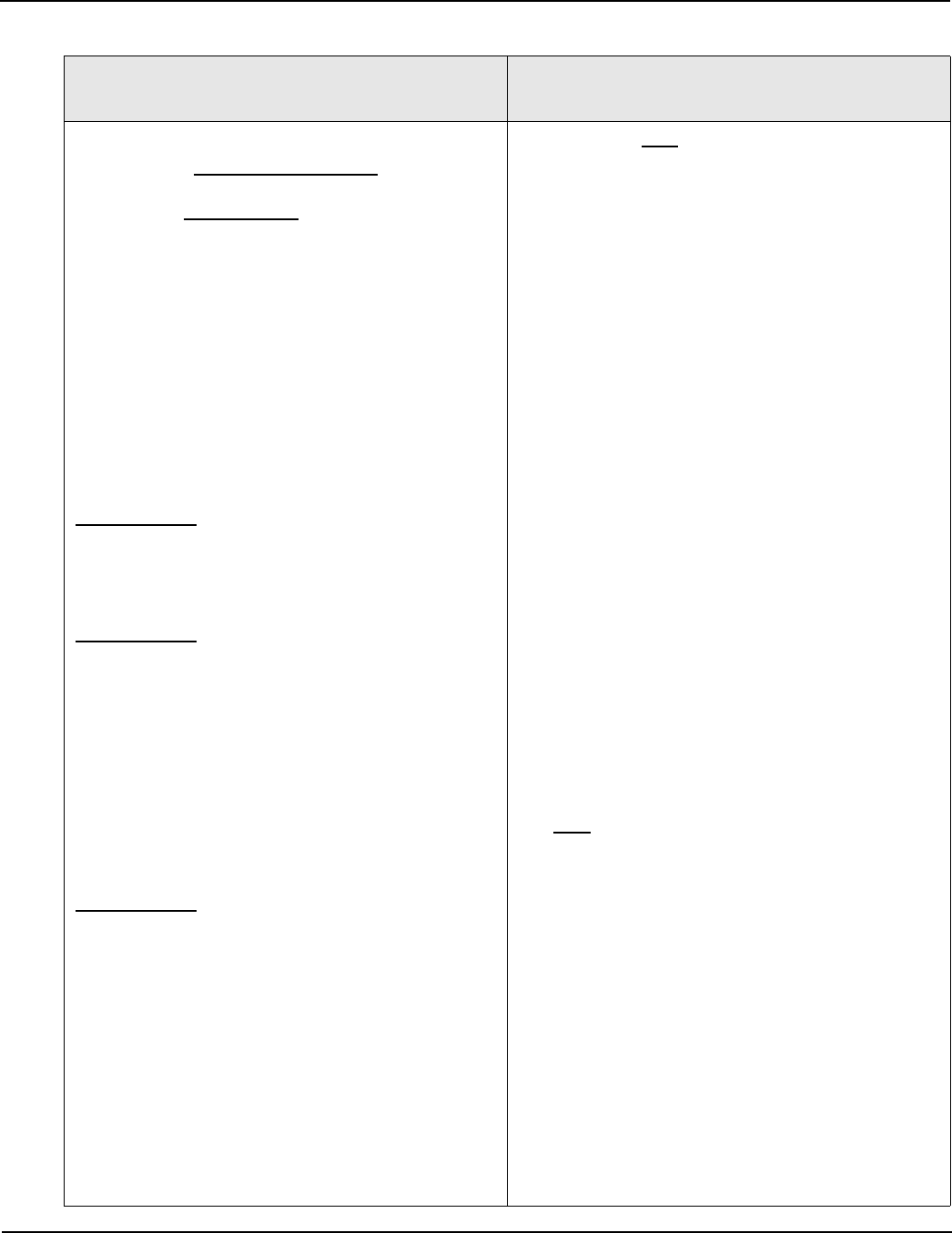

ERROR MESSAGES (CONT)

DISPLAYED MESSAGE

CONDITION/INDICATES

CHECK/REPAIR

“Blower Prov Stg1”

Blower Is Starting

(If the blower is not starting go to the “Blower Prov

Stg1” Blower Is Not Starting

tables)

Helpful Troubleshooting Note:

The state of the contacts for the Low BPS can be

viewed in real time using the System Status Menu.

An asterisk will appear next to the “BlwLo Prv” menu

item when the switch contacts are closed. The

asterisk is not present when the switch contacts are

open.

Three conditions can cause this error message

when the blower is starting:

Normally Open Low Blower Prover or High Blower

Prover pressure switch contacts are not closing

during the pre or post purge operating states - or

within 5 minutes of call for heat being activated.

OR

Normally Open High Blower Prover pressure switch

contacts did not re-open after pre purge operating

state was completed. The High Blower Prover switch

is used to prove adequate purging of the combustion

chamber during pre and post purge cycles only. The

blower runs at approximately 5000 rpm during pre

and post purge operating states and at lower speeds

during all other operating states. High blower prover

switch contacts must close during the pre and post

purge states ONLY and open during all other

operating states.

OR

Normally Open Low Blower Prover pressure switch

contacts have opened during any operating state

when the blower should be running. IE: This can be

caused due to blower failure during the heating cycle

or if the pressure sensed by the switch rises above

the switches activation pressure for any reason. The

normally open contacts on both Blower Prover

switches close on a fall in pressure - the pressure

sensed must be in a vacuum.

Operational Note:

See blower prover switch information on page 24

and the Sequence of Operation on page 15.

Determine if Low BPS is causing the lock out.

• The normally open Low BPS (BPS = Blower

Prover Switch) switch must close its contacts

after the blower starts. The Low BPS contacts

must remain closed whenever the blower is run-

ning to avoid the “Blower Prov Stg1” lock out.

Turn power off; disconnect the two wires to the

Low BPS. See panel layout on page 24 to deter-

mine which is the Low BPS.

Prepare a jumper wire to jumper between the

two wires just disconnected. Turn the boiler

back on, ensure a call for heat is present.

AFTER the blower motor starts jumper the two

(24 VAC) wires together carefully. Do not let the

wire ends touch any grounded surface.

Notice whether or not the boiler will continue

operation to the igniter warm up period when

the igniter is energized or locks out again on

“Blower Prov Stg1.” Clip an amp meter around

one of the igniter wires to see when the igniter

warm up period begins.

If the boiler will not continue on to the igniter

warm up period and locks out again on “Blower

Prov Stg1” before the igniter is energized; the

Low BPS is not causing the lock out. Turn off

power to the boiler and reconnect the wires to

the Low BPS. Continue on to: “Determine if

High

BPS is causing the lock out” in the table on

page 54.

If the boiler operation continues on to the igniter

warm up period without lock out. The Low BPS

is causing the lock out condition. Continue on to

the: “Pressure Reading Test” on page 55.