VF BOILER SERVICE MANUAL

AOS WPC - Tech Training 14 of 72 Ashland City, TN © 2007

Servicing should only be performed by a Qualified Service Agent

PRINCIPLE OF OPERATION (CONT)

Config Key - Blower Speed Programming

The Config Key is an 18” long cable with a plug on one end and an EEPROM memory chip

sealed at the other. The Config Key plugs into the J23 socket on the MCB Daughter Board

(see pages 25 and 34). The memory chip contains blower speed programming data specific

to the input Btu/hr and fuel type for each VF boiler. VF boilers are available in natural and

propane gas and in three input Btu/hr sizes; 500,000 - 750,000 - 1,000,000. There are 6

different Config Keys. High altitude Config keys may be produced in the future.

Current production Config Keys (VF boilers) are certified up to 7700 foot elevation.

Each time the boiler is powered up the MCB reads and then stores the blower speed

programming data from the Config Key into it’s own internal memory. The MCB then uses

the data to modulate blower speed by sending 1-10 VDC instructions to the VFD (page 11).

Modulating blower speed also modulates the firing rate on VF boilers (page 12).

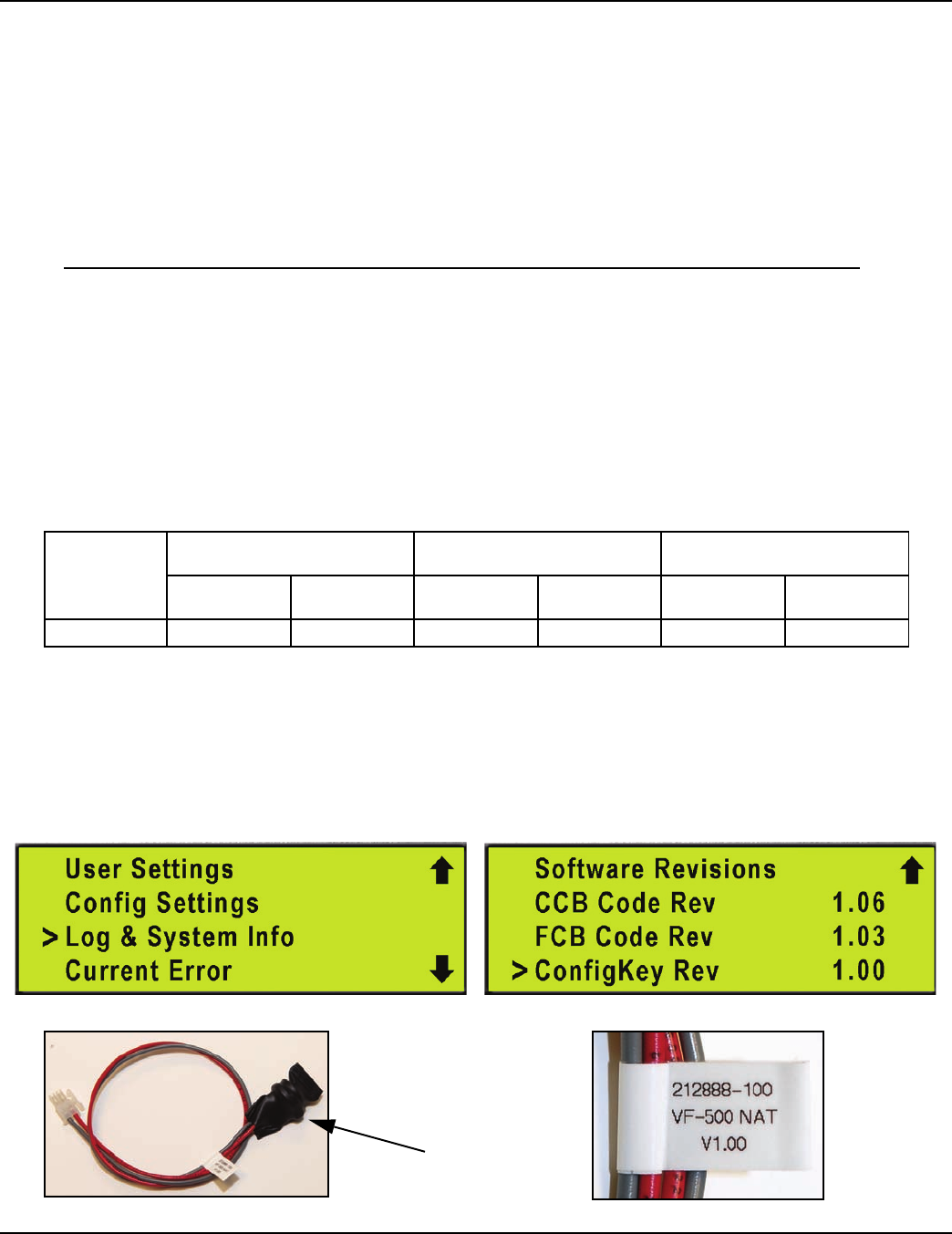

There is a label at the end of the Config Key cable near the memory chip. This end of the

cable is threaded into the wiring chase during production. The quickest way to verify the

correct Config Key is installed is to navigate to the Log & System Info menu in the UIM

pages 4 - 9) and compare the software revision number to the table below.

Memory Chip

Natural Gas Propane Gas Natural Gas Propane Gas Natural Gas Propane Gas

Rev #

1.00 1.01 1.10 1.11 1.20 1.21

Config Key

Software

Revisions

VW/VB 500 VW/VB 750 VW/VB 1000

Log & System Info menu

Config Key Label

Current Config Key Software Revisions

Even revision numbers are for natural gas models, odd numbers are for propane.

1.00 - 1.09 range for VW/VB 500 models

1.10 - 1.19 range for VW/VB 750 models

1.20 - 1.29 range for VW/VB 1000 models

Config Key

Press Menu

Navigate to Log & System Info

Press Select

Navigate to ConfigKey Rev