Basic Operation of the T801 Analyzer Teledyne API T801 NDIR CO2 Analyzer Operation Manual

60

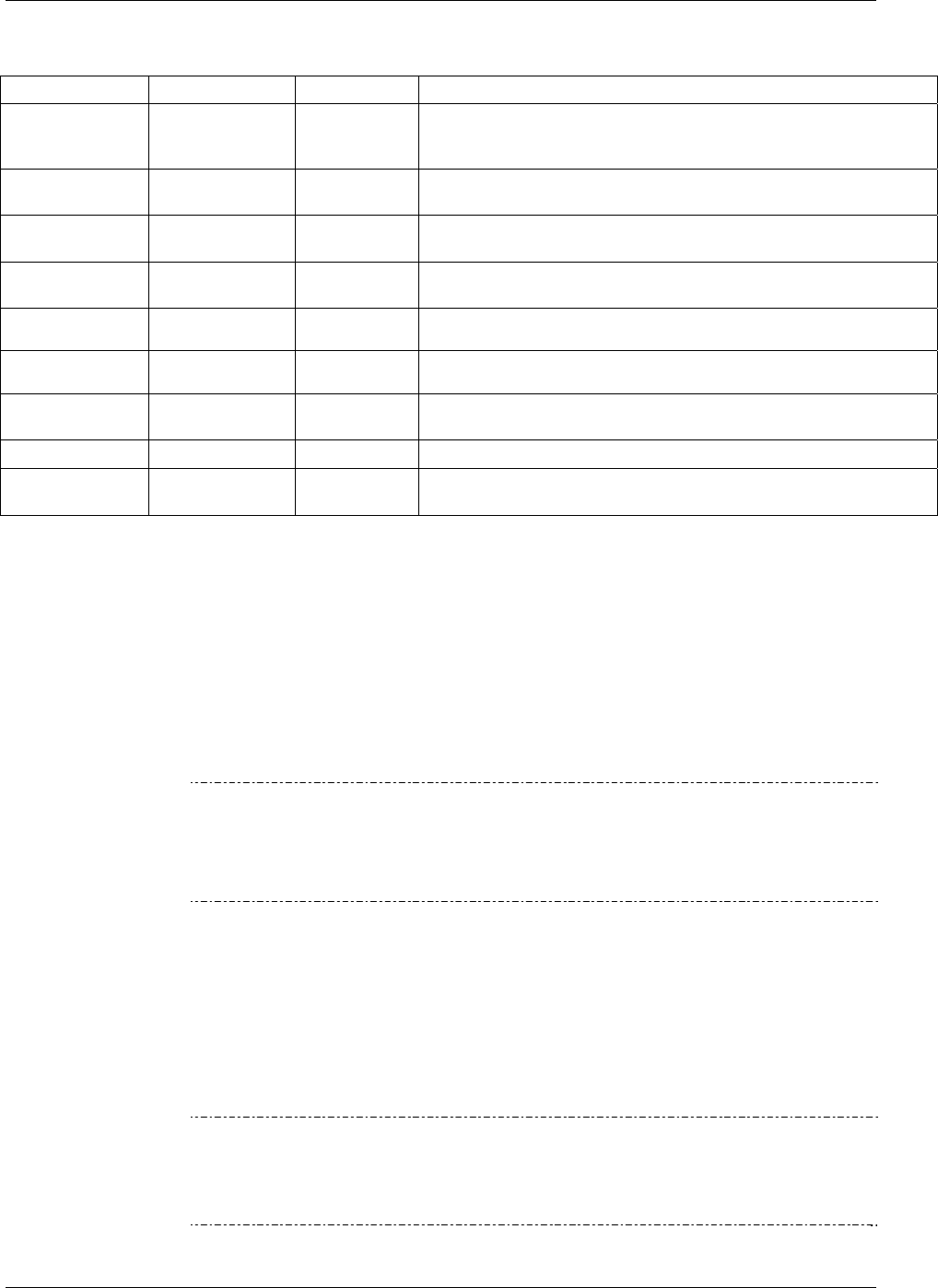

Table 4-2: Test Functions Defined

PARAMETER DISPLAY TITLE UNITS DEFINITION

Range

RNG

RN1

RN2

%

The full scale limit at which the reporting range of the analyzer is

currently set. THIS IS NOT the Physical Range of the instrument.

See Section 5.4.1 for more information.

Stability

STABIL

%

Standard deviation of CO

2

concentration readings. Data points are

recorded every ten seconds using the last 25 data points.

Sample Pressure

PRES

In-Hg-A

The absolute pressure of the Sample gas as measured by a

pressure sensor located inside the sample chamber.

Sample Flow

SAMP FL

cm

3

/min

Sample mass flow rate as measured by the flow rate sensor in the

sample gas stream.

CO

2

Sensor

Slope

CO2 SLOPE

- CO

2

slope, computed during zero/span calibration.

CO

2

Sensor

Offset

CO2 OFST

- CO

2

offset, computed during zero/span calibration.

CO

2

Cell

Temperature

CO2 CELL

TEMP

C

The current temperature of the CO

2

sensor measurement cell.

Box Temperature

BOX TEMP

C

The temperature inside the analyzer chassis.

Current Time

TIME

-

The current time. This is used to create a time stamp on DAS

readings, and by the AUTOCAL feature to trigger calibration events.

4.3. CALIBRATION MODE

The T801 will switch into calibration mode when the user presses the CAL

button. In this mode the user can, in conjunction with introducing zero or span

gases of known concentrations into the analyzer, cause it to adjust and recalculate

the slope (gain) and offset of the its measurement range. This mode is also used

to check the current calibration status of the instrument.

Section 9 provides more information about setting up and perform

ing standard

calibration operations or checks.

Note

It is recommended that span calibration be performed at 80% of full scale of

the analyzer’s currently selected reporting range.

EXAMPLE: If the reporting range is set for 0 to 10%, an appropriate span

point would be 8%.

4.4. SETUP MODE

The SETUP mode is used to configure the analyzer’s hardware and software

features, perform diagnostic procedures, gather information on the instrument’s

performance and configure or access data from the internal data acquisition

system (DAS) (Section 7). SETUP Mode has a Primary and a Secondary setup

menu.

Note

Any changes made to a variable during one of the SETUP procedures are not

acknowledged by the instrument until the ENTR button is pressed. If the EXIT

button is pressed before the ENTR button, the analyzer will beep to notify the

user that the newly entered value has been lost.

07274B DCN6418