Getting Started Teledyne API T801 NDIR CO2 Analyzer Operation Manual

52

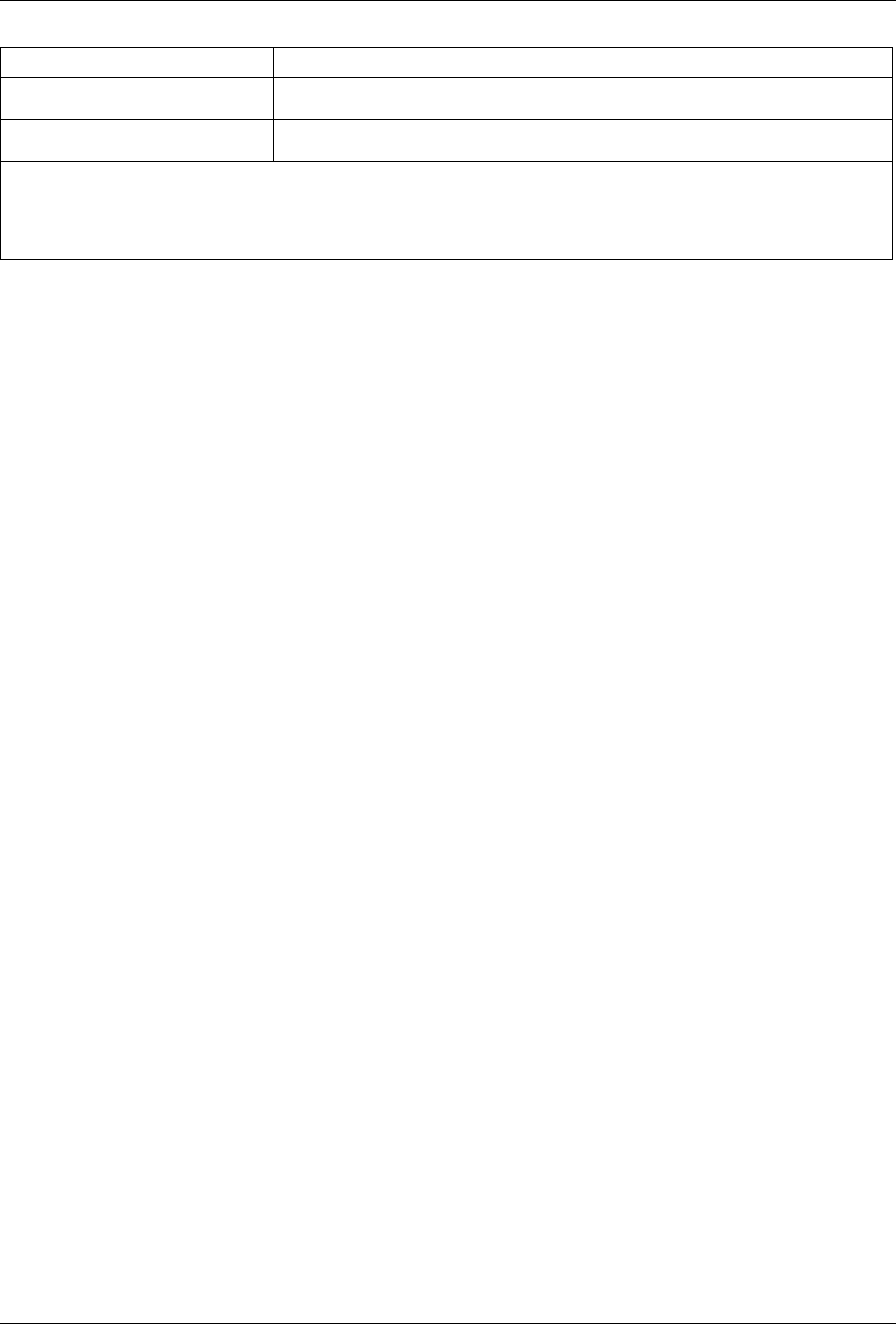

MESSAGE DEFINITION

SAMPLE PRESS WARN

Sample gas pressure outside of operational parameters.

SYSTEM RESET

1

The analyzer was rebooted or the CPU was reset.

1

Does not clear after power up.

2

Clears the next time successful span calibration is performed.

3

Clears the next time successful zero calibration is performed.

4

Only active if the Concentration Alarm Option is installed

3.4.2. FUNCTIONAL CHECKS

After the analyzer’s components have warmed up for at least 60 minutes, verify

that the software properly supports any hardware options that were installed. For

information on navigating through the analyzer’s software menus, see the menu

trees described in Appendix A.1.

Check to make sure that the analyzer is functioning within allowable operating

parameters. Appendix C includes a list of test functions, viewable from the

analyzer’s front panel, and their expected values. These functions are also useful

tools for diagnosing performance problems (Section 11.1.2) with your analyzer.

The enclosed Final Test and Validation Data Sheet (PN 068340

000) lists these

values before the instrument left the factory. To view the current values of these

parameters, press the front panel button sequence for TEST functions. Remember

until the unit has completed its warm up these parameters may not have

stabilized.

If your local area network (LAN) is running a dynamic host configuration

protocol (DHCP) software package, the Ethernet will automatically configure its

interface with your LAN. However, it is a good idea to check these settings to

make sure that the DHCP has successfully downloaded the appropriate network

settings from your network server (see Section 6.3.1).

If yo

ur network is not running DHCP, see your network administrator or

configure the Ethernet interface manually (see Section 6.3.2).

3.4.3. INITIAL CALIBRATION

To perform the calibration you must have sources for zero air and span gas

available for input into the SAMPLE port on the back of the analyzer. See

Section 3.3.2.1 for instructions for connecting these gas sources.

The initial calibration should be carried out

using the same reporting range set up

as used during the analyzer’s factory calibration. This will allow you to compare

your calibration results to the factory calibration as listed on the Final Test and

Validation Data Sheet.

If both available DAS parameters for a specific gas type are being reported via

the instrument’s analog outputs e.g. CONC1 and CONC2 when the DUAL

range mode is activated, separate calibrations should be carried out for each

parameter.

07274B DCN6418