Troubleshooting and Service Teledyne API T801 NDIR CO2 Analyzer Operation Manual

188

In general, flow problems can be divided into three categories:

1. Flow is too high

2. Flow is greater than zero, but is too low, and/or unstable

3. Flow is zero (no flow)

When troubleshooting flow problems, it is crucial to confirm the actual flow rate

without relying on the analyzer’s flow display. The use of an independent,

external flow meter to perform a flow check as described in Section 10.3.4 is

essential.

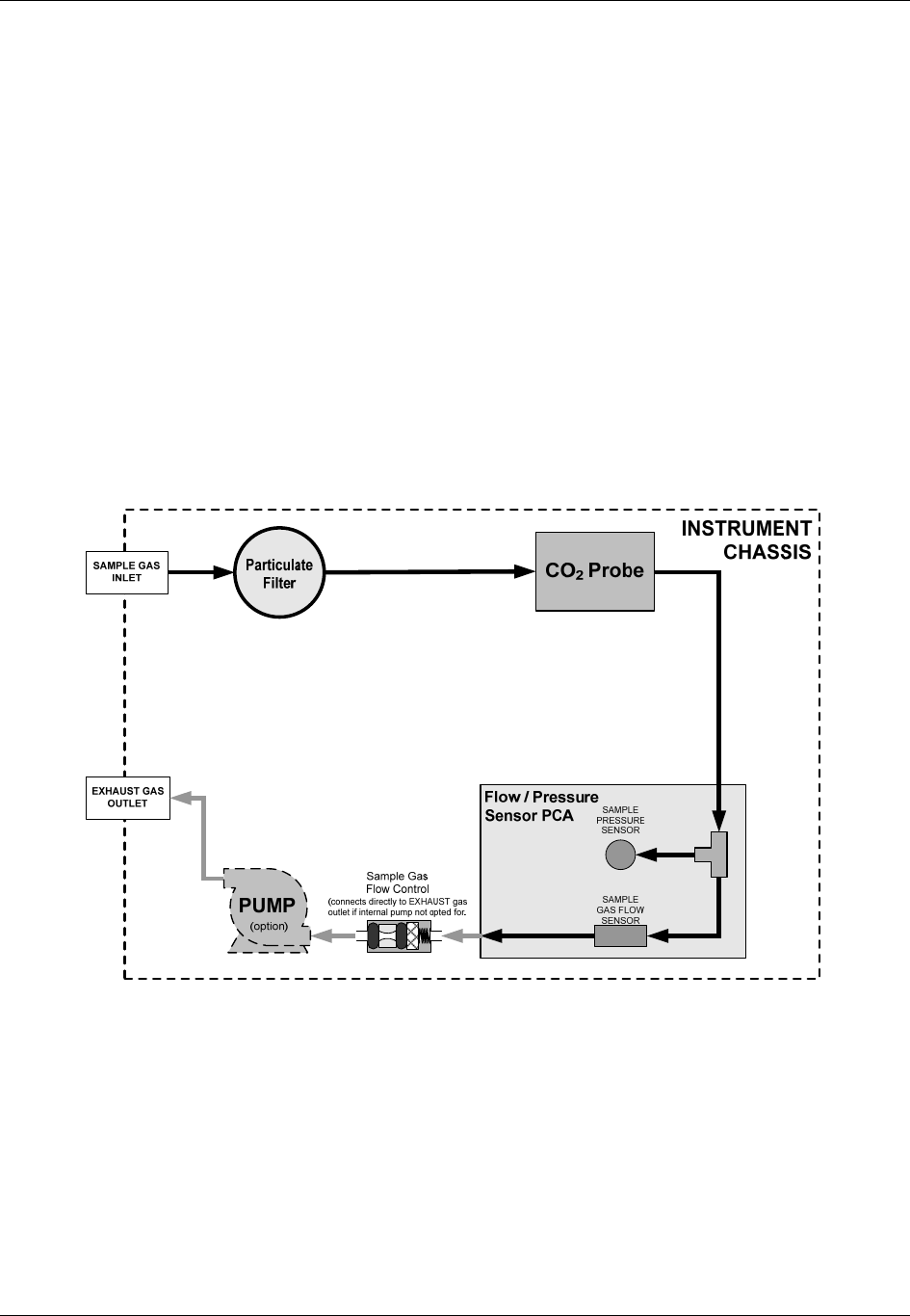

The flow diag

rams found in a variety of locations within this manual depicting

the T801 in its standard configuration and with options installed, can help in

trouble-shooting flow problems. For your convenience the diagrams are collected

here.

11.3.1. T801 INTERNAL GAS FLOW DIAGRAMS

Figure 11-5: T801 – Internal Gas Flow

11.3.2. TYPICAL SAMPLE GAS FLOW PROBLEMS

11.3.2.1. FLOW IS ZERO

The unit displays a SAMPLE FLOW warning message on the front panel display

or the SAMPLE FLOW test function reports a zero or very low flow rate.

Confirm that the sample pump is operating (turning). If not, use an AC voltmeter

to make sure that power is being supplied to the pump. If no power is present at

the electrical leads of the pump, take the following steps:.

07274B DCN6418