201

Introduction to the Quaternary Pump

Overview

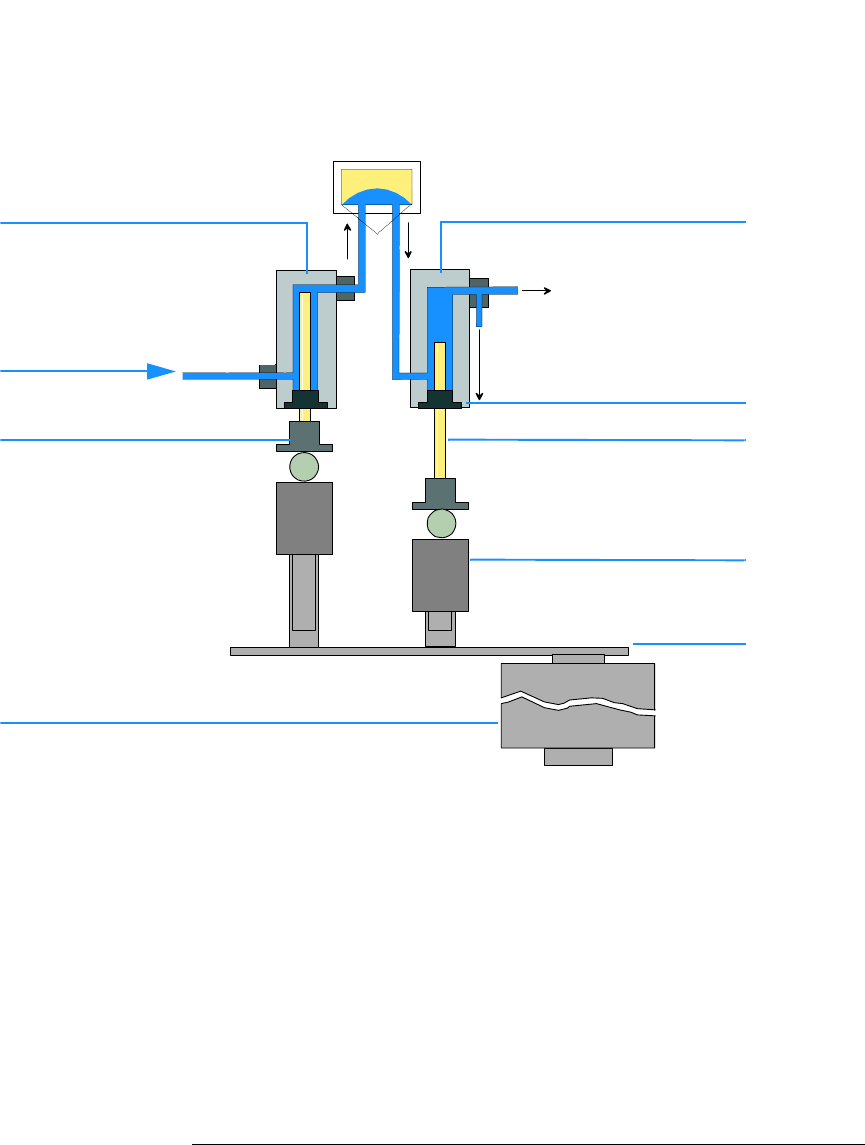

Figure 42 Principle of the Quaternary Pump

When turned on, the quaternary pump runs through an initialization

procedure to determine the upper dead center of the first plunger. The first

plunger moves slowly upwards into the mechanical stop of chamber and

from there it moves back a predetermined path length. The controller stores

this plunger position in memory. After this initialization the quaternary pump

starts operation with the set parameters. The active inlet valve is opened and

the down-moving plunger draws solvent into the first chamber. At the same

time the second plunger is moving upwards delivering into the system. After

a controller-defined stroke length (depending on the flow rate) the drive

motor is stopped and the active inlet valve is closed. The motor direction is

reversed and moves the first plunger up until it reaches the stored upper limit

and at the same time moving the second plunger downwards. Then the

sequence starts again moving the plungers up and down between the two

limits. During the up movement of the first plunger the solvent in the

From solvent bottle

Inlet

valve

Outlet

valve

Damper

To mixing chamber

Seal

Chamber 1

Ball screw drive

Motor with encoder

Gear

To waste

Purge valve

Plunger 2

Chamber 2

Plunger 1