46 RTAC-SVX01F-EN

Installation - Mechanical

Water Pressure Relief Valves

CAUTION

Shell Damage!

To prevent shell damage, install pressure relief valves in the evaporator

water system.

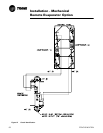

Install a water pressure relief valve in the evaporator inlet piping between the evapo-

rator and the inlet shutoff valve, as shown in Figure 25. Water vessels with close-cou-

pled shutoff valves have a high potential for hydrostatic pressure buildup on a water

temperature increase. Refer to applicable codes for relief valve installation guidelines.

Freeze Protection

If the unit will remain operational at subfreezing ambient temperatures, the chilled

water system must be protected from freezing. Heaters are factory-installed on the

packaged unit evaporator and will help protect it from freezing in ambient tempera

-

tures down to -20°F (-29°C).

Install heat tape on all water piping, pumps, water box nozzles and other components

that may be damaged if exposed to freezing temperatures. Heat tape must be

designed for low ambient temperature applications. Heat tape selection should be

based on the lowest expected ambient temperature.

Add a non-freezing, low temperature, corrosion inhibiting, heat transfer fluid may also

be added to the chilled water system. The solution must be strong enough to provide

protection against ice formation at the lowest anticipated ambient temperature. Refer

to

Table 1 through Table 5 in the General Information section for evaporator water

storage capacities.

NOTE: Use of glycol type antifreeze reduces the cooling capacity of the unit and

must be considered in the design of the system specifications.

CAUTION

Evaporator Damage!

ALL unit chilled water pumps must be controlled by the Trane CH530 to

avoid catastrophic damage to the evaporator due to freezing. Refer to

RLC-PRB012-EN.

Low Evaporator Refrigerant Cutout and % Glycol

Recommendations

1. Solution freeze point is 4 deg F below operating point saturation temperature.

2. LRTC is 4 deg F below freeze point.

Procedure

1. Is operating condition contained within Table 9? If no see “Special” below.

2. For leaving fluid temperatures greater than 40 deg F, use settings for 40 deg F.

3. Select operating conditions from Table 9.

4. Read off recommended % glycol.

5. Go to Table 10. From the % glycol.