160 RTAC-SVX01F-EN

Maintenance Procedures

oil will result in high oil circulation rates which will foul the condenser and evaporator

performance. This will result in inefficient operation of the chiller. Taken to an

extreme, high oil levels may result in erratic expansion valve control or shut down of

the chiller due to low evaporator refrigerant temperature. Too much oil may contribute

to long term bearing wear. Additionally, excessive compressor wear is probable when

the compressor is started with the oil lines dry.

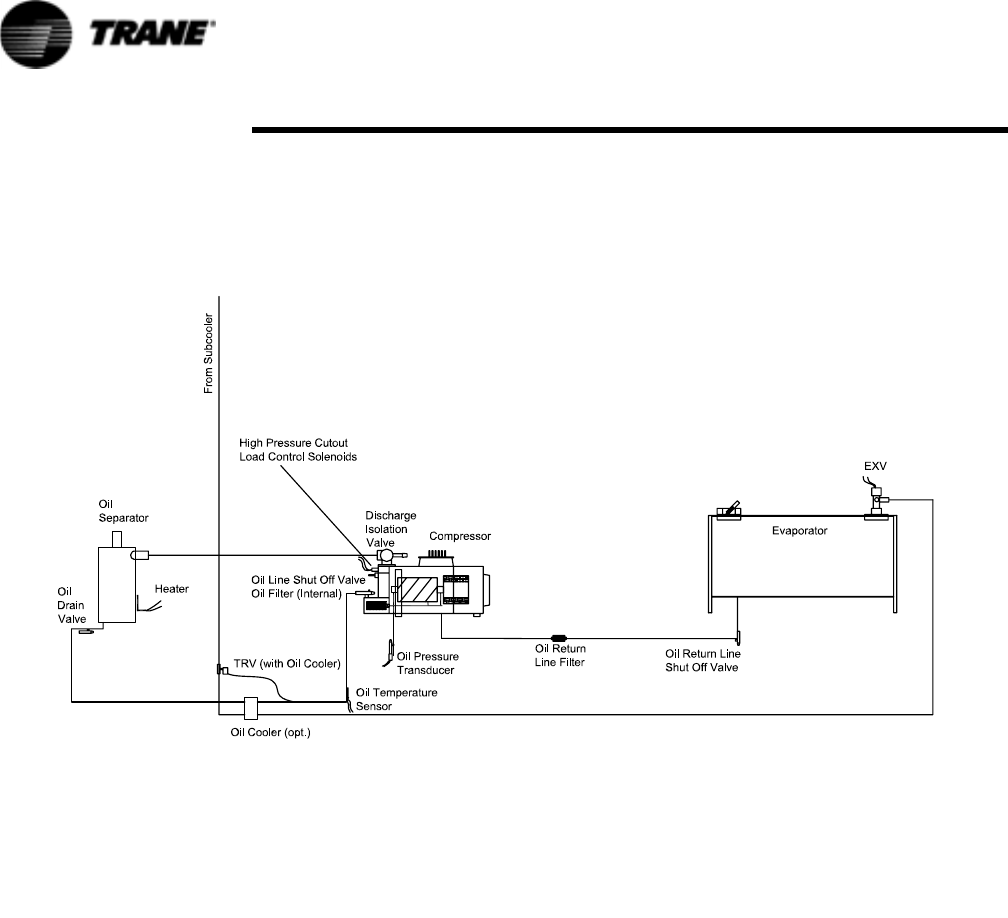

Figure 46 Oil System Schematic

Oil system consists of the following components:

• Compressor

• Oil separator

• Discharge line with service valve

• Oil line from separator to compressor

• Oil line drain (lowest point in system)

• Oil cooler - optional

• Oil temperature sensor

• Oil line shut off valve with flare service connection

• Oil filter (internal to compressor) with flare fitting service connection and schrader

valve

• Oil flow control valve (internal to the compressor after the filter)

• Oil return line from evaporator with shut off valve and strainer

Refer to Table 1 - Table 5 for the standard oil charge for each circuit.

NOTE: Recommendation: check the oil level in the sump using a sight glass or a

manometer, attached to charging hoses.